Moistureproof, mildewproof and anti-static spraying device

A technology of spraying device and conformal paint, applied in the direction of spraying device, can solve the problems of low spraying efficiency, low efficiency, complicated design, etc., and achieve the effect of good spraying effect, high spraying efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

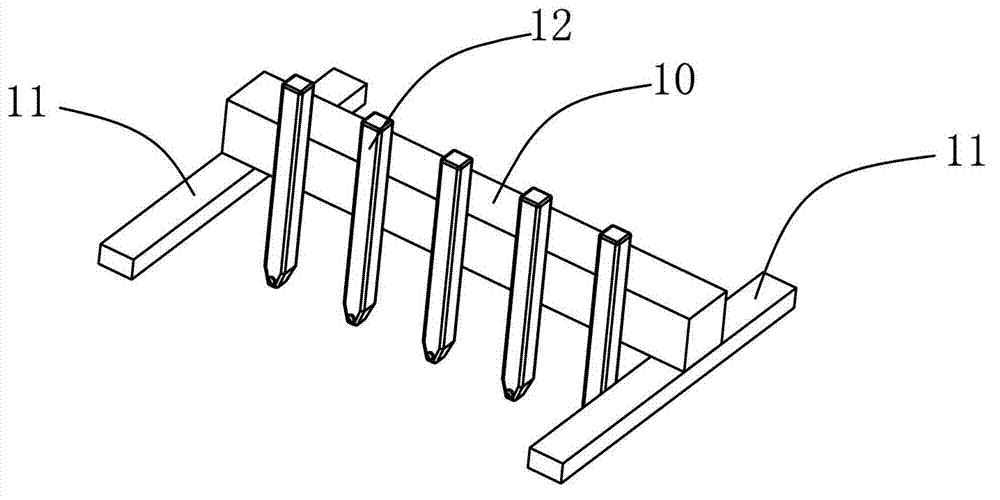

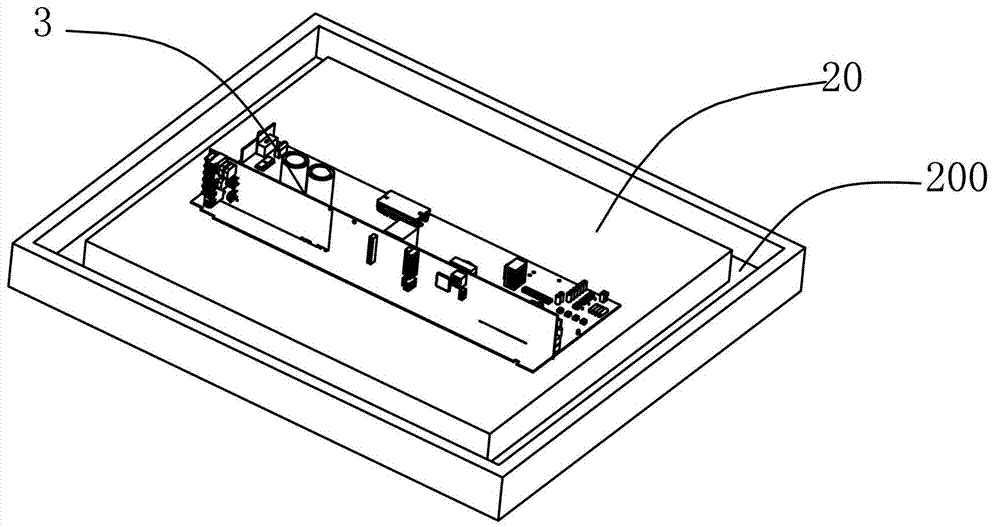

[0024] The invention discloses a three anti-paint spraying device, which combines figure 1 and figure 2 As shown, it includes a spraying assembly 1 that can rise and fall and a conveying assembly 2 located below the spraying assembly 1. The spraying assembly 1 includes a crossbeam 10, two horizontal rails 11 that are slidably connected with the crossbeam 10 and are located on A plurality of spray guns 12 on a beam 10 capable of rotating along its axis. In the above-mentioned structure, when the PCB board 3 is carried on the conveying assembly 2 and conveyed to the spraying position, the appropriate spraying distance is reached through the rise or fall of the spraying assembly 1, and then the beam 10 slides back and forth on the two horizontal rails 11, so that The spray gun 12 can evenly spray the conformal paint on the entire PCB board 3 . W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com