Color indicating epoxy resins and methods thereof

A technology for epoxy resin and curing epoxy resin, which is applied in the field of dyes and can solve problems such as difficulty in detecting completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0146] Advantages and embodiments of this invention are further illustrated by the following examples, but the particular materials and amounts thereof recited in these examples, as well as other conditions and details, should not be construed to unduly limit this invention. In these examples, all percentages, ratios and ratios are by weight unless otherwise indicated.

[0147] All materials are commercially available, eg, from Sigma-Aldrich Chemical Company; (Milwaukee, WI), or are known to those of skill in the art unless otherwise indicated or apparent.

[0148] Table 1 Materials

[0149]

[0150]

[0151] Preparation of Component A (amine-based curing agent) 20 g of TTD Mix with 10 wt.% (2.0 g) of silica for 2 minutes. Subsequently, the dye is added in fractional steps of 5 mg until a good visual impression of the color can be obtained. After each addition, the mixture was again mixed using the mixer for 1 minute at 3500 rpm.

[0152] Preparation of component B...

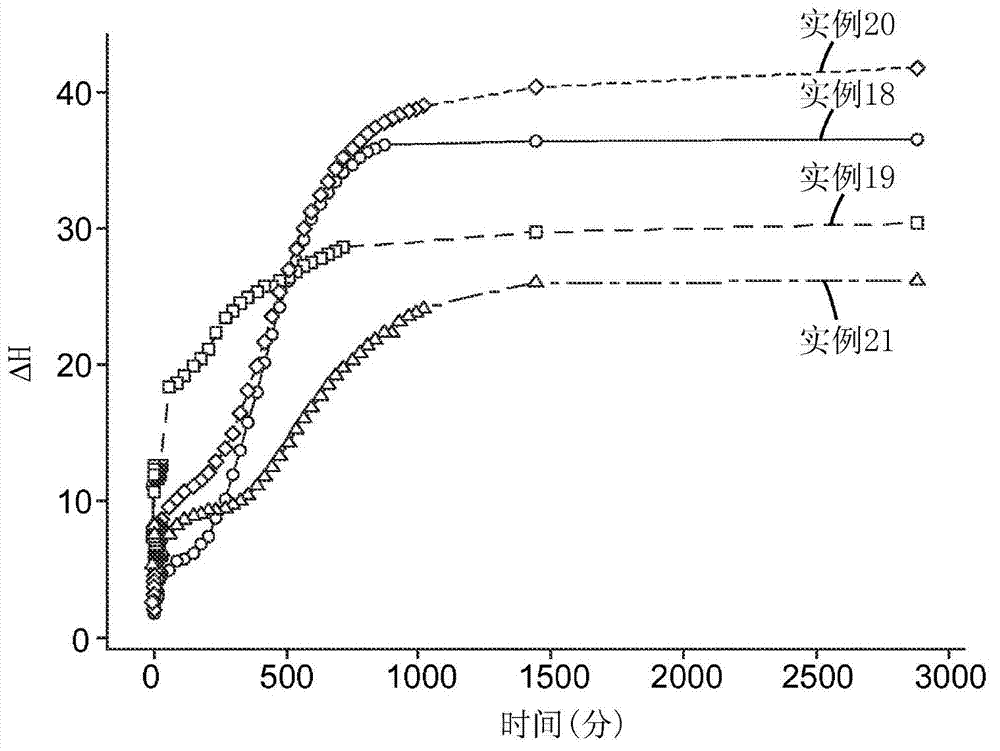

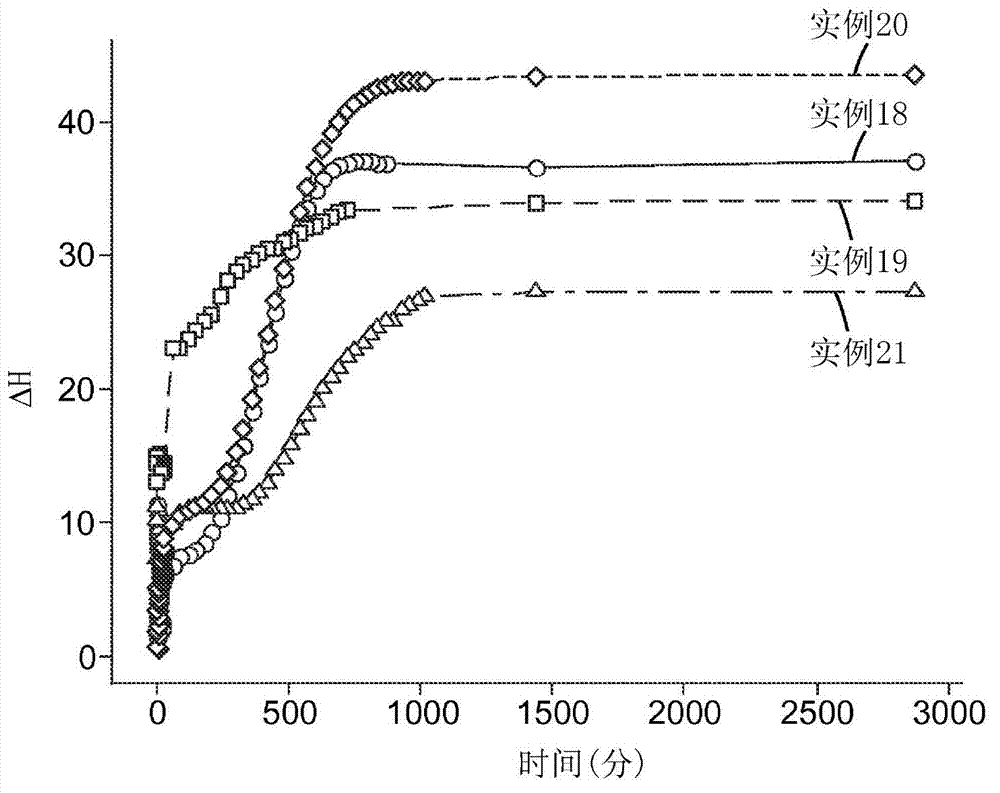

example 18

[0164] Example 18: The preparation of Component C listed above was prepared using Dye 10 in an amount of 0.25 wt%. The preparation of Component D listed above was prepared using 0.18 wt% of Dye 8.

example 19

[0165] Example 19: The preparation of Component C listed above was prepared using Dye 13 in an amount of 0.25 wt%. The preparation of Component D listed above was prepared using 0.18 wt% of Dye 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com