Insulating and anti-cracking structure and construction method of bus pier of aluminum electrolytic workshop

An aluminum electrolysis and workshop technology, applied in infrastructure engineering, construction, etc., can solve problems such as large load of busbar piers and fracturing at the top of busbar piers, and achieve the effect of ensuring safe production, improving compressive strength, and not easily crushed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

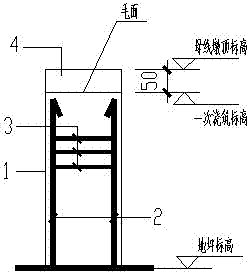

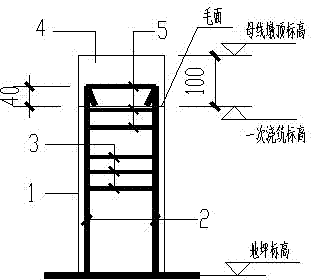

[0009] Attached below figure 2 The present invention will be described in further detail with specific embodiments.

[0010] The structure of the present invention is: it comprises reinforced concrete buttress 1, steel bar 2, stirrup bar 3, and steel bar 2 is higher than one pouring elevation 40mm, and the top of steel bar 2 is provided with encrypted stirrup bar 5 and steel bar 2 welding, secondary fine stone concrete The leveling layer 4 has a thickness of 100mm.

[0011] Construction method of the present invention is as follows:

[0012] In the first step, the reinforced concrete pier 1 is constructed to 100mm below the required level, but the short column steel bar 2 needs to be extended to 40mm above the primary pouring level, and three encrypted stirrup bars 5 need to be placed on the top of the steel bar 2, and they must be connected with the steel bar 2 Solder firmly.

[0013] In the second step, after the concrete pier 1 reaches the design strength, the construct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com