Method for carrying out scenting treatment to improve quality of tobacco leaves in tobacco leaf aging process

A tobacco leaf and scenting technology, which is applied in the field of scenting tobacco leaves, can solve the problems of high cost, long time consumption, miscellaneous gas and irritation, etc., and achieve the effects of low cost, simple process, and improved smoking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (1) Take commercially available finished tangerine peels, wrap each 14 kg tangerine peels with a single layer of absorbent cotton gauze, and wrap them into several tangerine peel bags.

[0014] (2) Tobacco leaf raw materials whose moisture content is controlled at 14% after re-curing are taken, and pre-pressed to form a smoke brick with a weight of 24 kg. The length, width and height of the smoke brick are 1100*680*100mm.

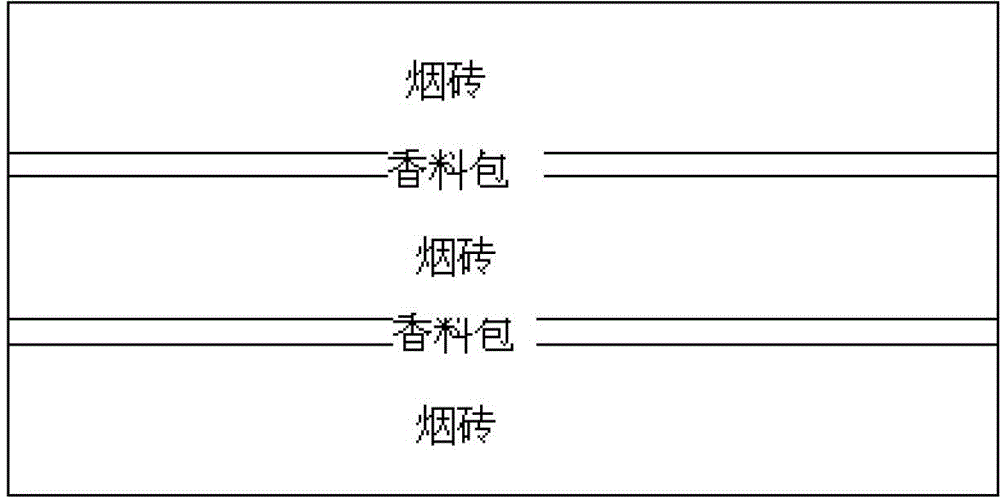

[0015] (3) Smoked bricks are stacked and stored, three smoked bricks are interlayered with two tangerine leather bags to form a group, wrapped tightly in a sealed plastic bag, then put into a carton with a size of 1115*690*400mm, and put into a normal aging In warehouse, natural aging for 2 years.

[0016] The specific mixing state of the smoke brick and the fragrant chrysanthemum bag is as follows: figure 1 shown.

Embodiment 2

[0018] (1) Take commercially available finished cinnamon, weigh 15 kg of chrysanthemum, wrap it with a single layer of absorbent cotton gauze, and wrap it into several cinnamon bags.

[0019] (2) Tobacco leaf raw materials whose moisture content is controlled at 13% after re-curing are taken, and pre-pressed to make tobacco bricks with a weight of 20 kg.

[0020] (3) Smoked bricks are stacked and stored, three smoked bricks are interlayered with two fragrant chrysanthemum bags to form a group, wrapped tightly in a sealed plastic bag, then put into a carton, put into a normal aging warehouse, and naturally aged for 1.5 years .

[0021] Table 1 Smoking description of sensory evaluation of tobacco leaves after scenting

[0022] sample number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com