Direct-in/direct-out servo electrical pick-up machine

A straight-in, straight-out, electric technology, used in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of large movement range of hinged four-bar structure, unsmooth longitudinal feed movement, and longitudinal feed jitter, etc. Shorten production cycle, save work space, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

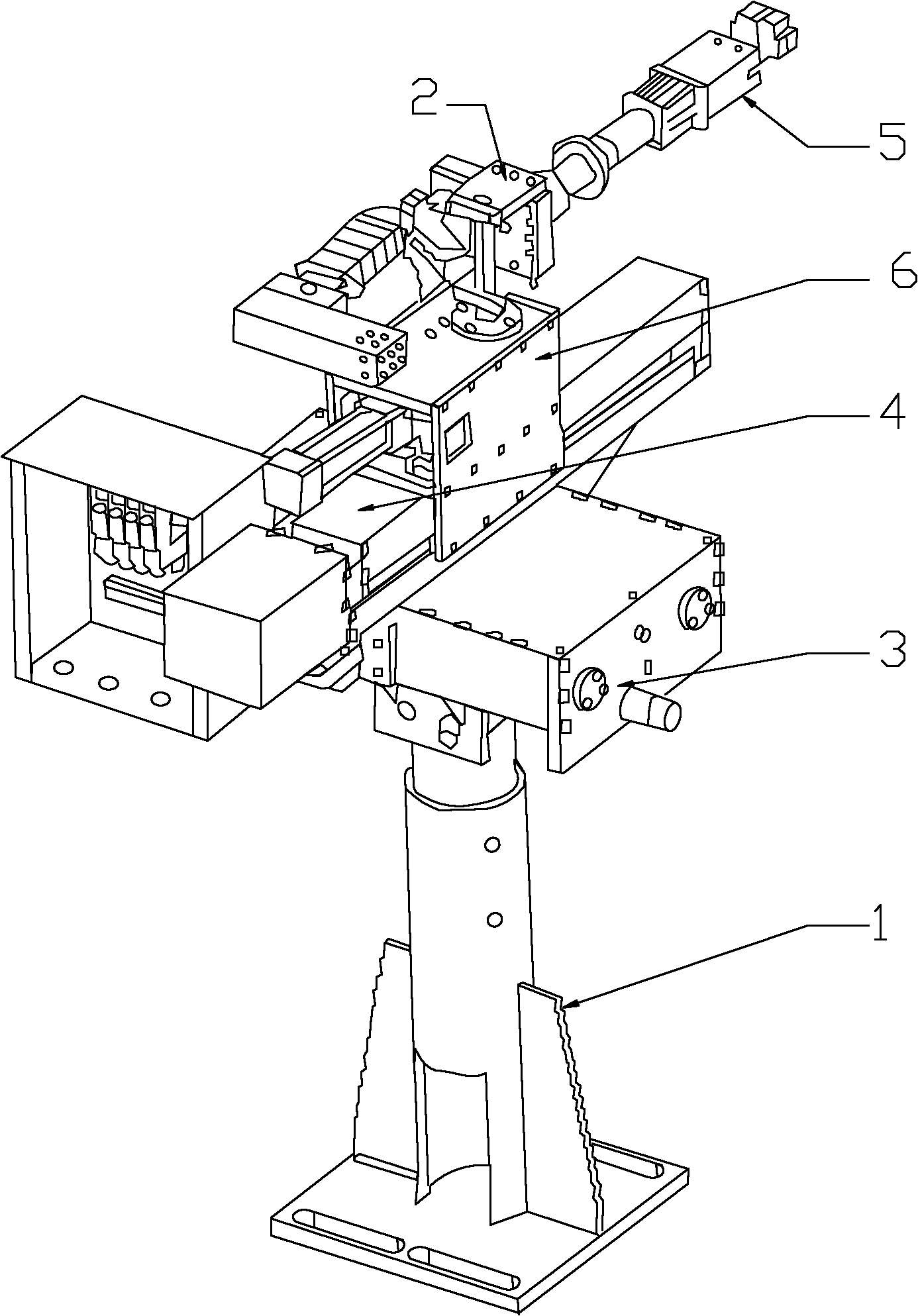

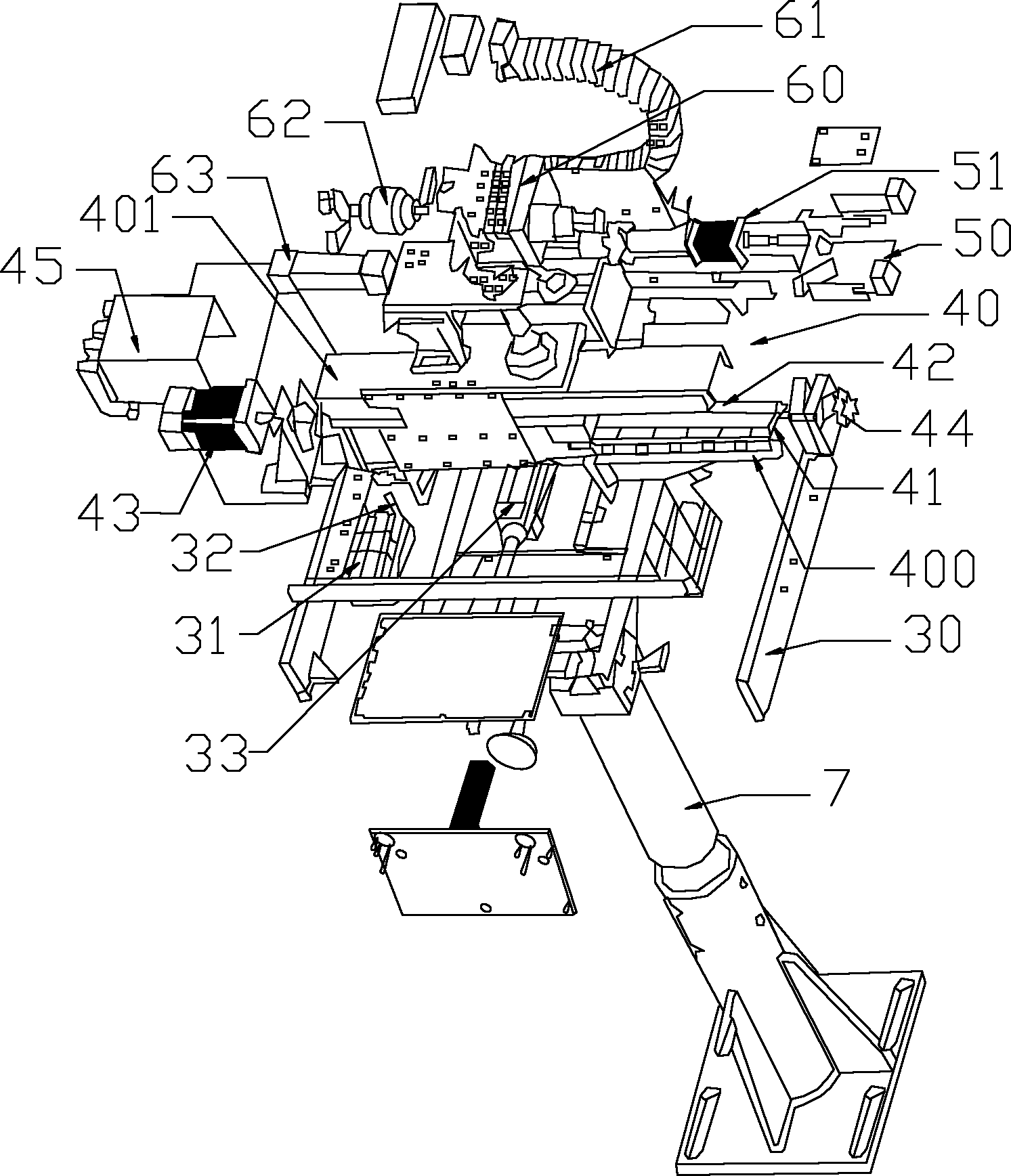

[0015] Such as figure 1 and figure 2 As shown, a straight-in and straight-out servo electric pick-up machine of the present invention includes a base 1, an arm 2 arranged on the base 1, a transverse feed mechanism 3 connected to the arm 2, a longitudinal feed mechanism 4, The arm clamp mechanism 5 and the arm horizontal rotation mechanism 6 have the advantages of saving working space, reducing the longitudinal stroke, shortening the production cycle, and improving work efficiency.

[0016] Wherein, the longitudinal feed mechanism 4 includes a casing 40 connected to the arm 2, a screw seat 41 arranged in the casing 40, a screw rod 42 arranged horizontally on the screw seat 41, and a screw rod 42 arranged on the screw seat 41. A servo motor 43 at one end of the screw mandrel 42 and engaged with the screw mandrel 42, and a bearing 44 arranged at the other end of the screw mandrel 42 and cooperating with the screw mandrel 42; the servo motor 43 is used to drive the screw mandrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com