Display and line sorting structure thereof

A wire management structure and wire management technology, which is applied in the direction of instruments, electrical digital data processing, digital data processing parts, etc., can solve the problems of wire management buckle jumping out of the shaft hole, high design difficulty, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

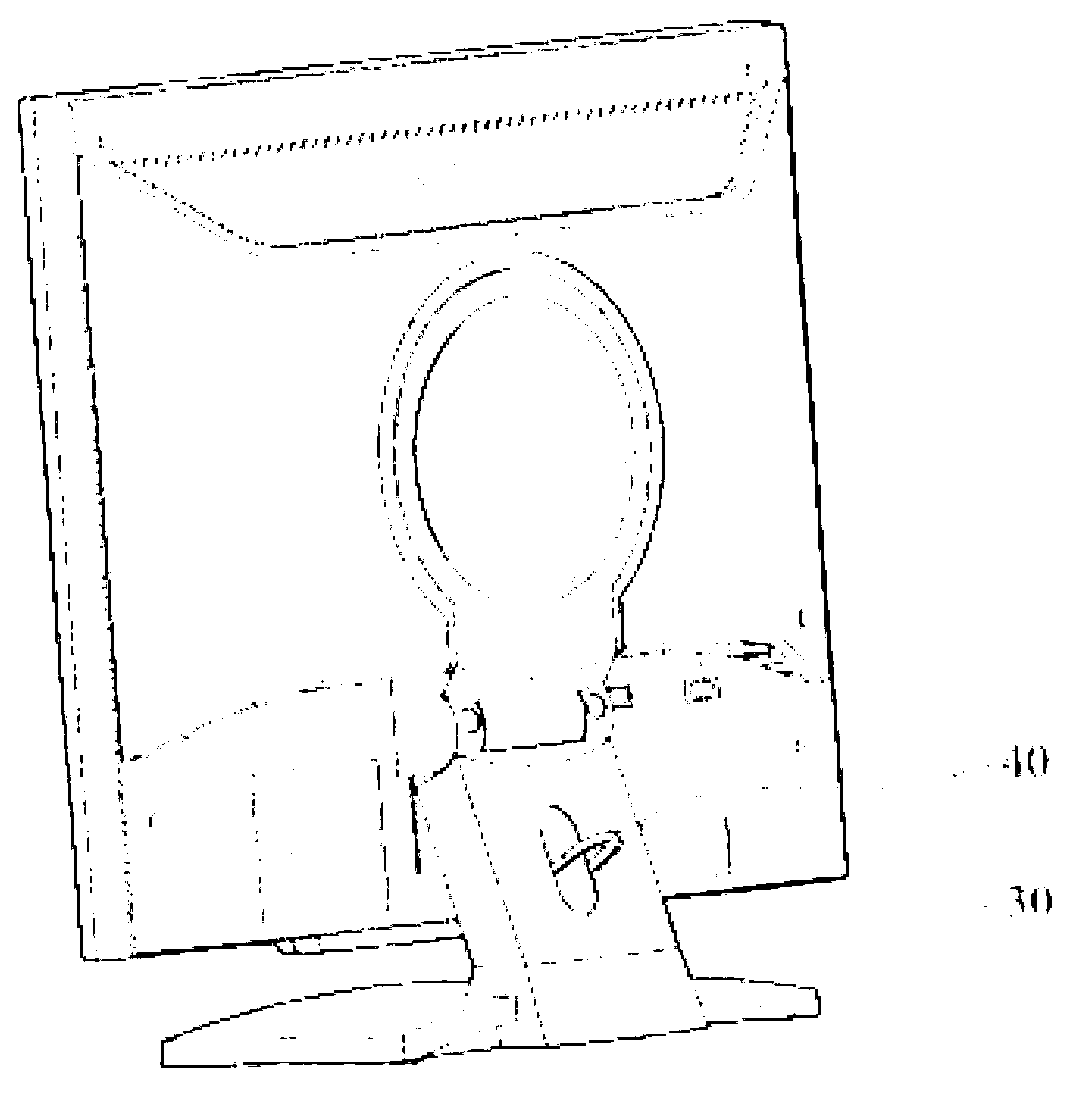

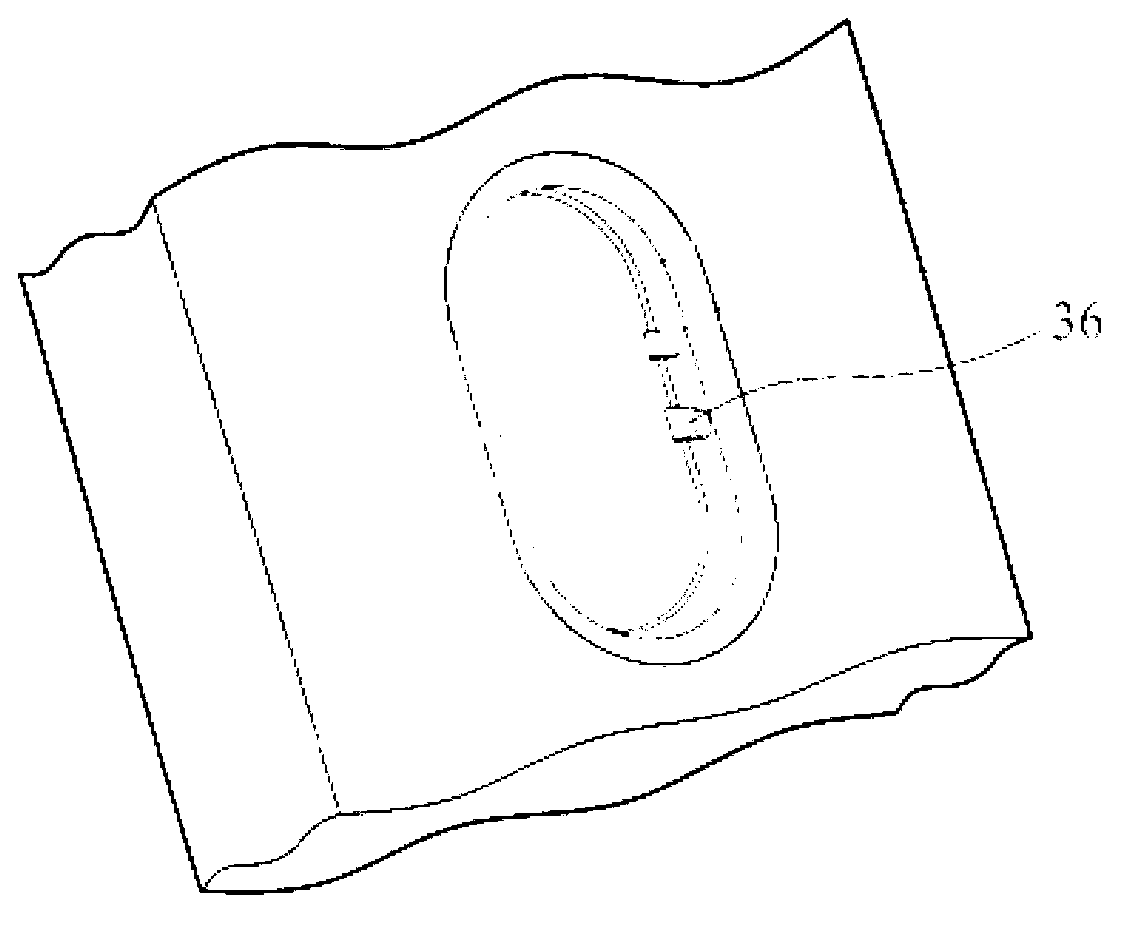

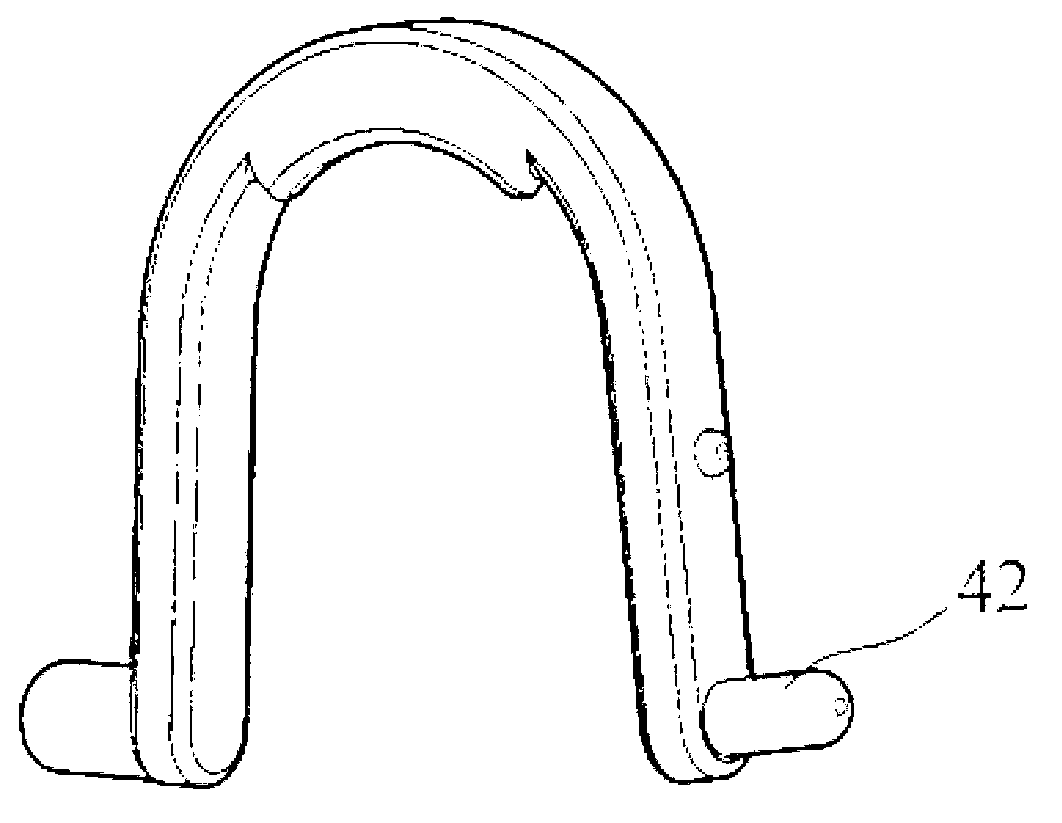

[0029] Please see Figure 4 , Figure 4 It is a structural schematic diagram of the display of the present invention. The display 100 includes a display body 10 , a cable management structure connected to the display body 10 , and a base 20 . The cable management structure includes a cable management buckle 30 and a support seat 40 . Such as Figure 5 and Figure 6 as shown, Figure 5 It is a schematic diagram of the cable management buckle of the cable management structure of the present invention, Figure 6 It is an enlarged schematic view of the first elastic arm of the cable management buckle of the present invention. The wire management button 30 has a button body 31 and two first elastic arms 32 connected with the button body 31. The button body 31 has a U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com