Fruit and vegetable cleaning machine

A fruit and vegetable cleaning machine and body technology, which can be used in home appliances, applications, kitchen utensils, etc., and can solve the problems of short residence time, low mixing efficiency, and clogged micropores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

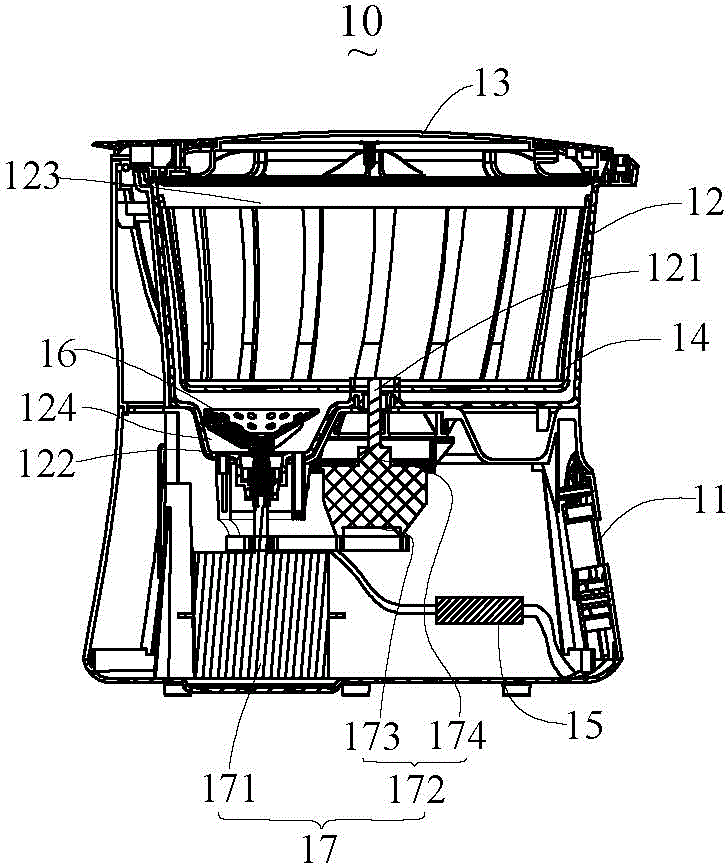

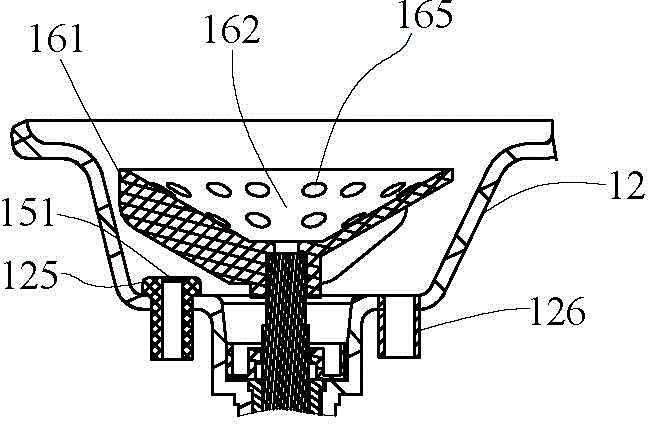

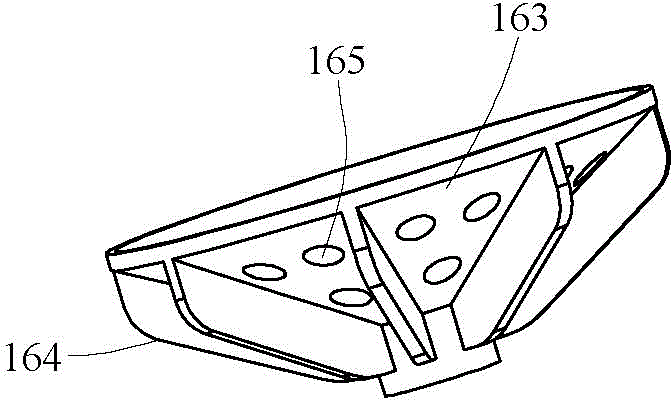

[0038] Please also refer to figure 1 , figure 2 As shown, the first embodiment of the fruit and vegetable cleaning machine of the present invention, the fruit and vegetable cleaning machine 10 includes a body 11, a washing bucket 12 for holding water, an upper cover 13, a washing basket 14 for holding fruits and vegetables, and the cleaning bucket 12 A washing rotating shaft 121 is provided, and the washing basket 14 is installed on the washing rotating shaft 121 , and the upper cover 13 is fastened to seal the washing tub 12 . The fruit and vegetable cleaning machine 10 also includes an ozone generator 15, an aeration device 16 and an aeration rotating shaft 122 arranged in the cleaning bucket 12, and the aerating device 16 is installed on the aeration rotating shaft 122, and the cleaning bucket 12 is provided with a connecting ozone The air inlet 151 of the generator 15. The body 11 is provided with a driving device 17 for driving the rotation of the washing shaft 121 and...

Embodiment approach 2

[0055] see Figure 4 , Figure 5 The difference between the shown second embodiment of the fruit and vegetable cleaning machine of the present invention and the first embodiment is that a filter 21 is provided at the bottom of the cleaning bucket 12 and the filter 21 is installed in the air inlet 151 .

[0056] The filter screen 21 can effectively prevent the stains of fruits and vegetables cleaned in the washing bucket 12 from blocking the air inlet 151 . In this way, the safety is further improved, and the smoothness of the ozone gas entering the cleaning tub 12 is guaranteed.

[0057] It can be understood that the fruit and vegetable cleaning machine of the present invention can also prevent the danger of dirt blocking the air intake hole during the drainage process through the structure of the baffle or the edge.

[0058] It can be understood that the filter screen of the present invention can also be covered on the air intake hole 151 .

[0059] In this implementation ...

Embodiment approach 3

[0061] see Figure 6 As shown in the third embodiment of the fruit and vegetable cleaning machine of the present invention, the difference between the fruit and vegetable cleaning machine 30 and the fruit and vegetable cleaning machine 10 is that the deceleration device 172 includes the input end 173 connected to the shaft of the motor 171 and the output end connected to the washing rotating shaft 121 A clutch 31 is provided between the input end 174, the input end 173 and the motor shaft.

[0062] In this embodiment, by setting the clutch 31, when the fruits and vegetables are cleaned, purified and disinfected, the clutch 31 is coupled, and the motor 171 drives the washing frame 14 and the aeration device 16 to rotate at the same time; The aeration device 16 rotates, and ozone water for sterilization and disinfection can be made in the cleaning barrel 12, so that this fruit and vegetable cleaning machine 30 has a multi-purpose function. Of course, the motor shaft of the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com