High-strength bolt strength calculating method of wind generating set

A technology for wind turbines and high-strength bolts, which is applied in computing, electrical digital data processing, special data processing applications, etc., can solve problems such as bolt stress deviation, failure to take into account the way of applying bolt pre-tightening force, and increased calculation costs. , to achieve the effect of improving reliability and simple and practical calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is a further description of the present invention.

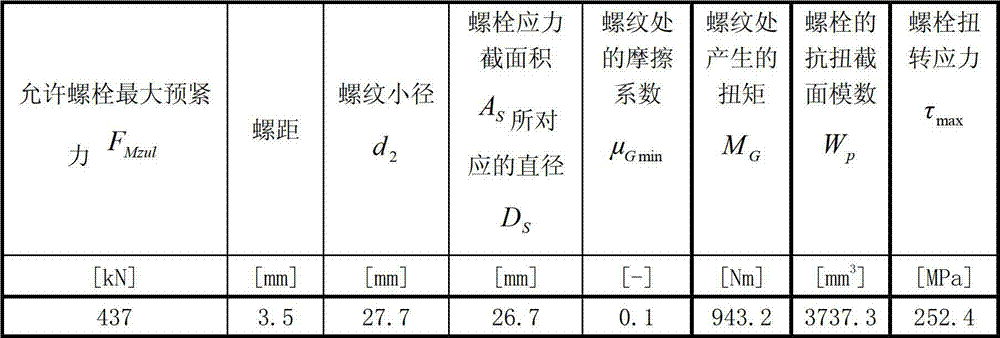

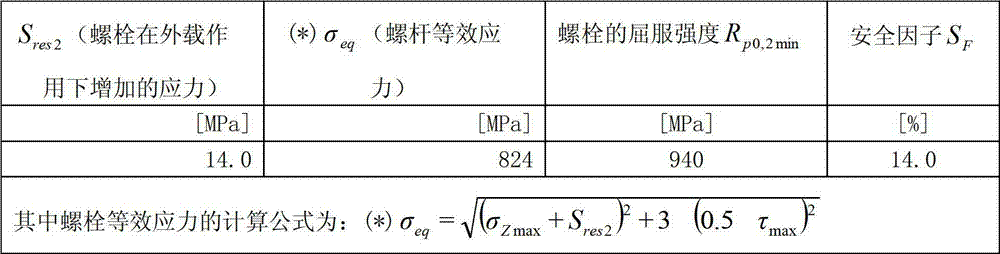

[0016] This example takes the calculation of the strength of high-strength bolts (M30) connecting the front and rear frames of the wind turbine as an example, and describes the specific calculation process of the bolt strength in detail as follows:

[0017] First, a finite element analysis model is established.

[0018] Use 3D software to establish the geometric model of the front and rear racks of the connected parts, convert it into a format recognized by the mesh software after assembly, and import it into the mesh software to divide all parts into meshes. The connected parts are all large metal structures, so solid meshes are used in the mesh division; in order to reduce the number of meshes, the bolts are simulated with three-dimensional beam elements. The connections are simulated by means of multi-point constraints.

[0019] Afterwards, the corresponding load boundary and constraint boundary con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com