Rapid hot melt type optical fiber connector

A connector and hot-melt type technology, applied in the coupling of optical waveguide, etc., can solve the problems of communication interruption, clamping of optical cable and connector shell, insufficient length of surplus section, etc., and achieve the effect of low success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

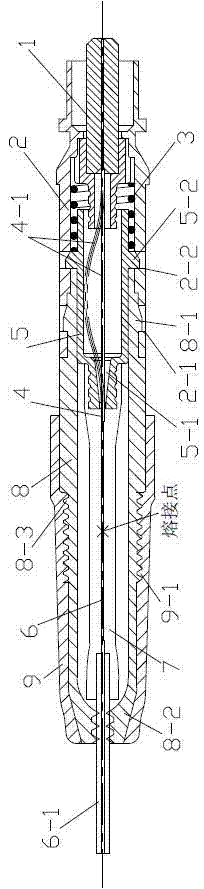

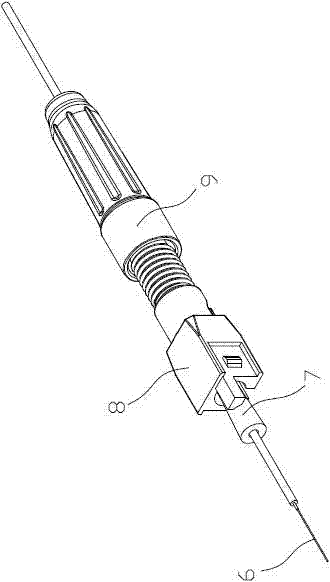

[0026] When assembling the hot-melt optical fiber connector on site, first thread the tightening nut 9, the tail shell 8, and the heat-shrinkable sleeve 7 into the optical fiber 6 at the cable end in sequence, and cut to length with a special tool. figure 2 .

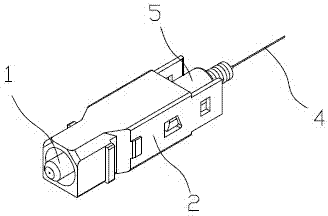

[0027] Put the prefabricated optical fiber 4 together with the connector housing 2 and the ferrule assembly 1 into a special tool for cutting to length, as shown in the attached image 3 .

[0028] Use a fiber optic fusion splicer to perform fiber fusion, and fuse the fiber 6 at the cable end and the prefabricated fiber 4 into a whole, as shown in the attached Figure 4 .

[0029] Put the heat-shrinkable sleeve 7 into the optical fiber fusion joint, and wrap one end on the outside of the inner tapered structure 5-1 of the connection bushing, and heat shrink it with a heat-shrinkable tube heating device to protect it outside the optical fiber fusion joint. Figure 5 .

[0030] Insert the tail shell 8 into the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com