A Suction Port for Improving Cavitation Performance of Centrifugal Pump

A suction port and centrifugal pump technology, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids, and can solve problems such as poor pump cavitation performance and low pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

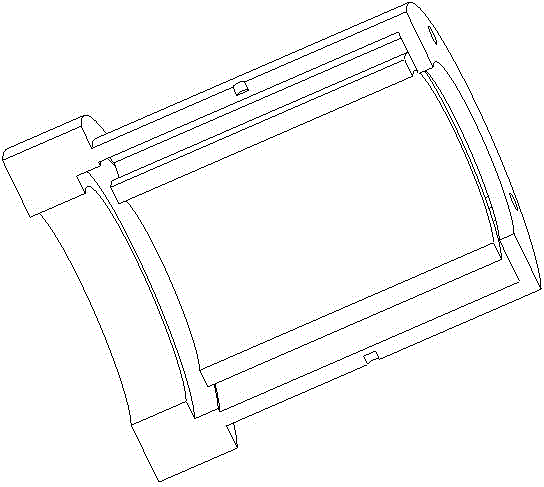

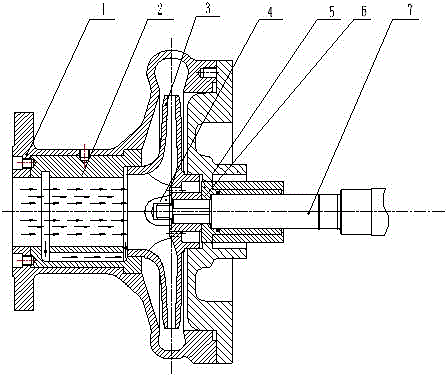

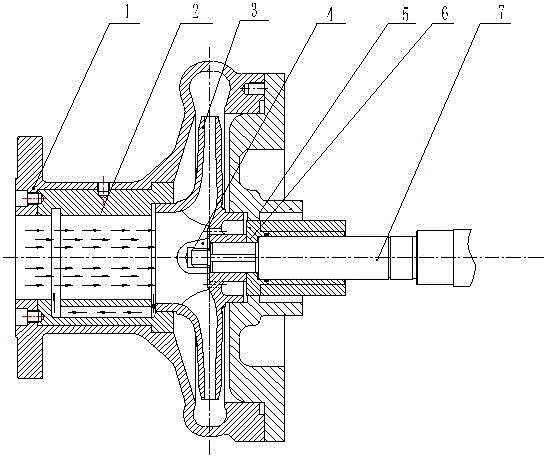

[0013] combine figure 1 , the centrifugal inlet structure of the present invention includes a backflow sleeve for reducing NPSH, the backflow sleeve is composed of an inner and outer two-layer annular inner ring and an outer ring, and the inner diameter of the inner ring of the backflow sleeve is consistent with the size of the pump flow channel , the outer diameter of the inner ring of the return sleeve is consistent with the size of the pump inlet of the pump body, the gap between the inner ring and the outer ring is one-twentieth of the outer diameter of the return sleeve, which is the flow channel of the return water, and the axial direction of the inner ring Both ends are shorter than the outer ring by one-twentieth of the outer diameter of the return sleeve, which is the inlet and outlet of the return water; there are 4 cube supports between the inner ring and the outer ring to connect the inner ring and the outer ring. Other structures of the centrifugal pump in the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com