Grouped pile structure for preventing and treating landslide and construction method thereof

A construction method and technology of group piles, which are applied in basic structure engineering, excavation, sheet pile wall, etc., can solve the problems of increasing project cost, construction period, material waste, etc., and achieve the goal of saving project cost, preventing damage and saving project cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

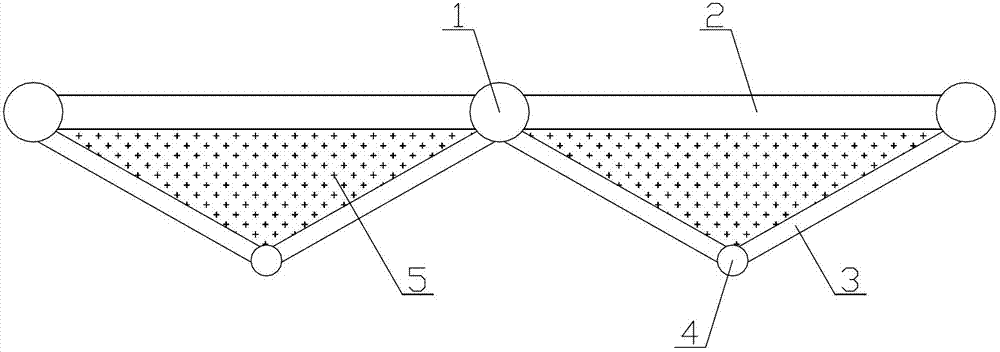

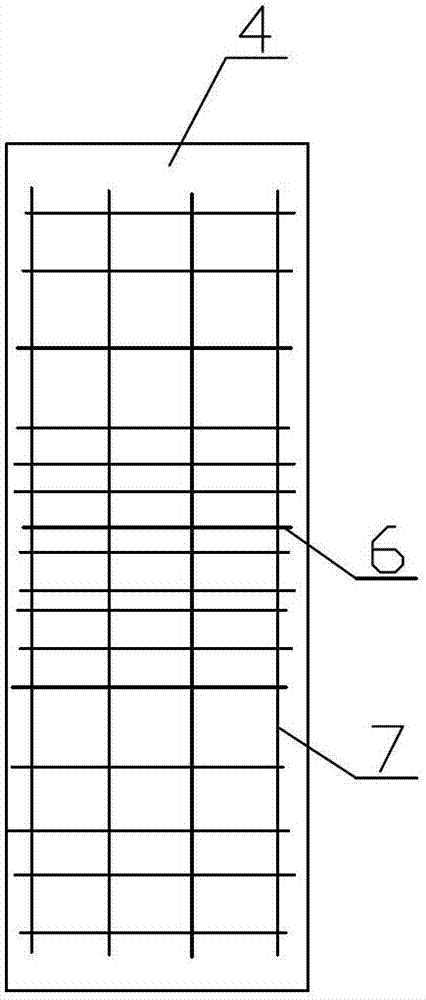

[0032] Such as figure 1 As shown, the invention discloses a pile group structure for preventing landslides, which is composed of a main anti-slide pile 1, a secondary anti-slide pile 4, a main crown beam 2, a secondary crown beam 3 and a green belt.

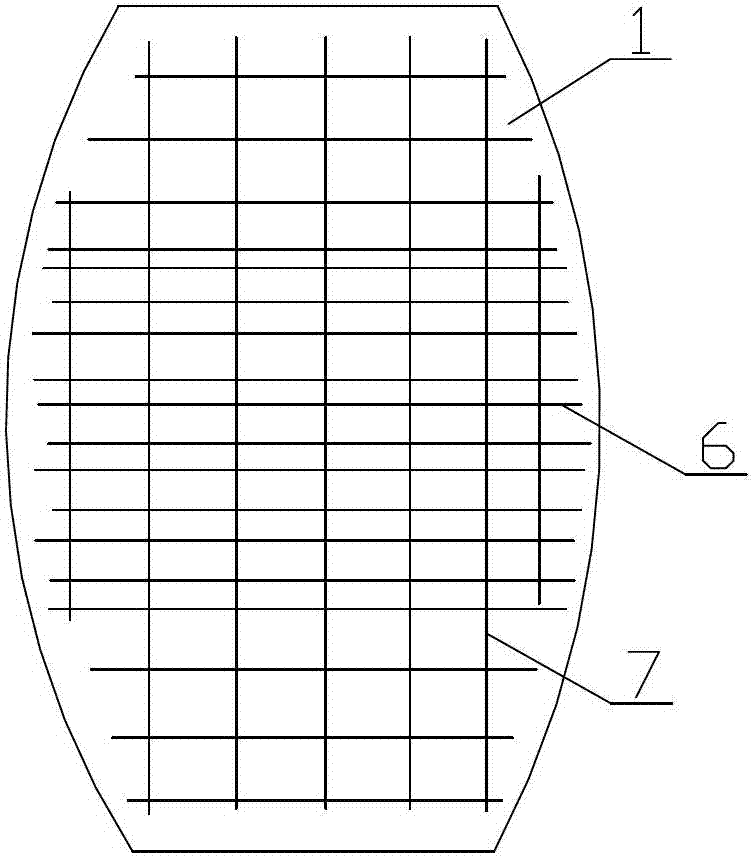

[0033] The main anti-slide piles 1 are arranged in one or more rows on the slope body according to the scale of the landslide and the sliding force. Such as figure 2 As shown, the shape of the main anti-slide pile 1 is thick in the middle and thin on both sides, and the thick and thin parts can be a smooth transition or a stepped transition, that is, the diameter of the middle part of the main anti-slide pile 1 is larger than the diameter of the upper and lower parts, and its minimum diameter is its max...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com