Full-automatic plastic bag sealing machine

A plastic bag and sealing machine technology, applied in packaging sealing/tightening, external support, transportation packaging, etc., can solve the problem of electric heating sealing clips closing each other and clamping, there is a gap, it is difficult for both ends of the beam to move synchronously, affecting the sealing quality, etc. problems, to achieve the effect of continuous operation process, more automation, convenient sealing operation, and improved automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

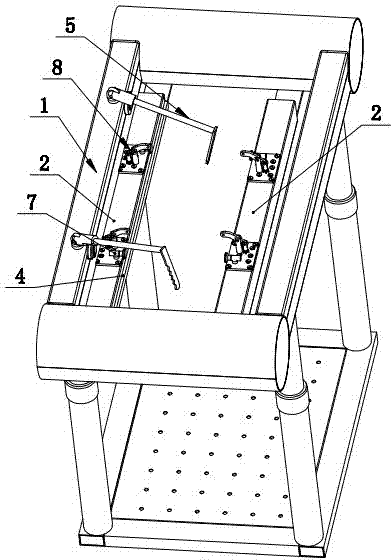

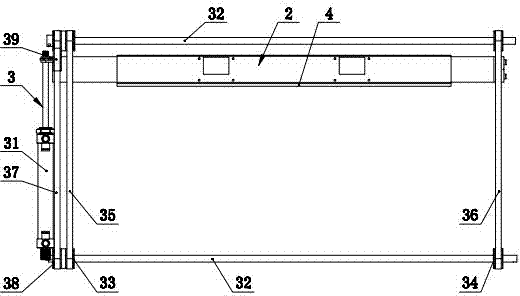

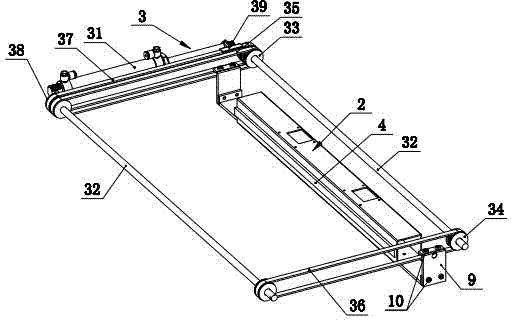

[0025] Such as figure 1 , 2, 3, 4, 5, 6, 7, and 8 show a fully automatic plastic bag sealing machine, including a body 1, and the body 1 is equipped with two oppositely moving crossbeams 2, each crossbeam 2 There is a set of transmission mechanism 3 that drives them to move back and forth in a horizontal straight line, and a piece of electric heating sealing clip 4 is fixedly installed on the opposite sides of the two beams 2, and there is a set on the top of the beam 2 for stretching and tensioning. The support rod 5 of the plastic bag and the swing mechanism 6 that drives the swing of the support rod 5, and the suction cup 7 and the plastic bag locking mechanism 8 for fixing the plastic bag are also installed on the described beam 2. Described strut 5 is made up of support knife 51, rocker arm connection shaft 52, rocker arm shaft 53, and rocker arm connection shaft 52 is placed horizontally, and described support knife 51 is placed vertically, and the front end of rocker a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com