Precise micro motion platform based on shape memory material coarse motion driver

A technology of micro-motion platform and memory material, which is applied in the field of micro-motion platform, can solve the problems of low positioning accuracy, cumbersome control process, and complex structure, and achieve the effects of high positioning accuracy, wide application prospects, and large output displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

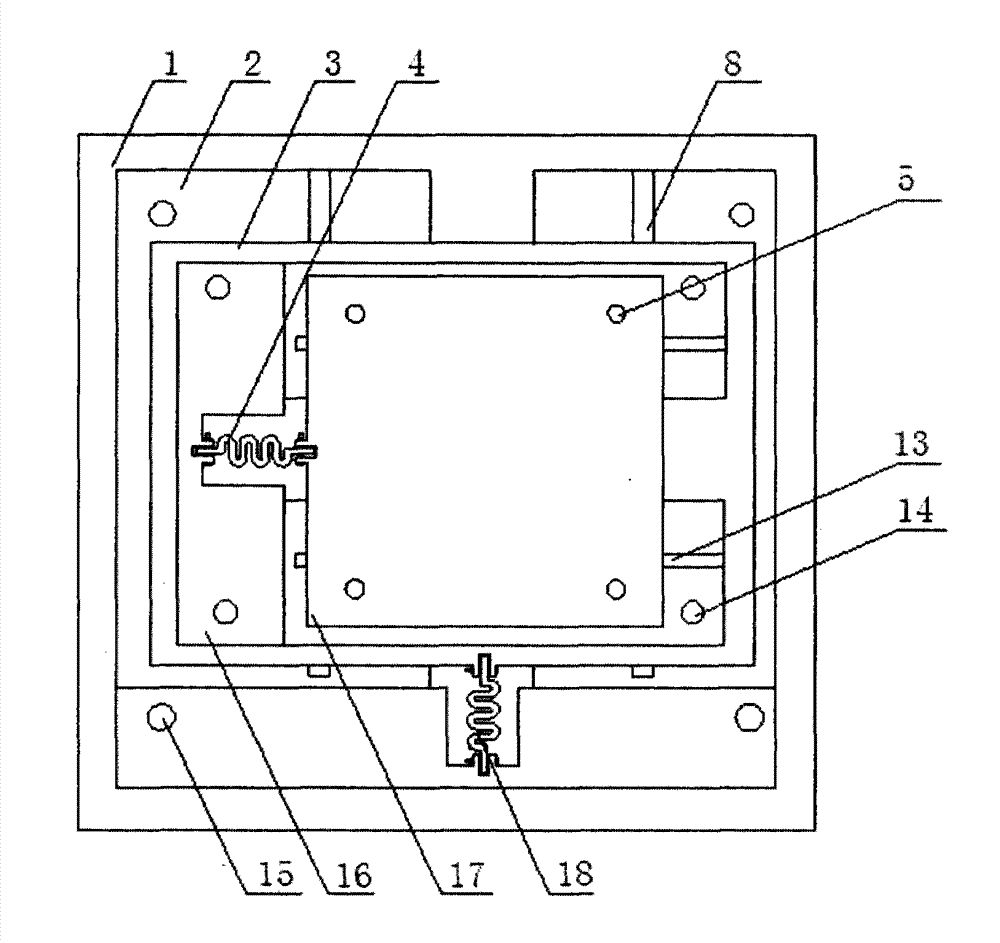

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A precision micro-motion platform based on a shape-memory material coarse motion driver. The stage 21 is fixed on the upper end surface of the Y-direction micro-motion platform 11 through the stage mounting bolts 10. The Y-direction micro-motion platform 11 passes four A Y direction micro-motion flexible hinge mechanism 9 is installed in the inside of X direction micro-motion platform 7; Y direction piezoelectric micro-driver 19 is installed in the drive groove of X direction micro-motion platform 7, and its two ends are connected with Y direction micro-motion platform respectively The moving platform 11 is in contact with the X-direction micro-movement platform 7; the X-direction micro-motion platform 7 is installed inside the base 12 of the XY two-dimensional micro-motion platform through four X-direction micro-movement flexible hinge mechanisms 20, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com