Method for dynamically setting parameters of coordinated control system on basis of preliminary coal supply control model

A technology for coordinating control systems and control models, applied in control/regulation systems, general control systems, adaptive control, etc., can solve problems such as control effects depending on the technical level of thermal engineers, complicated parameter tuning process, and difficulty in establishing mathematical models. , to achieve the effect of shortening the calculation time, high precision and large time span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

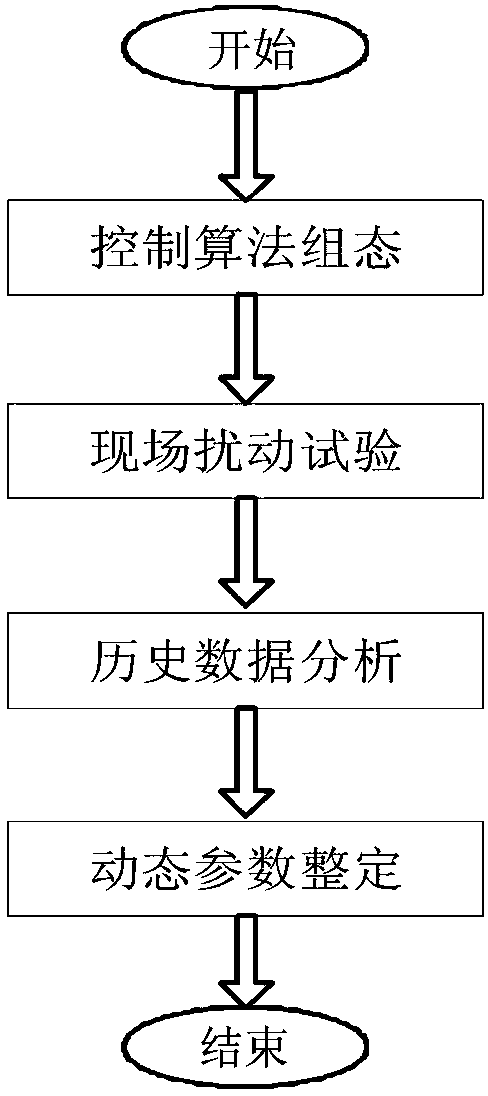

[0031] The present invention is a method for dynamically setting parameters of a coordinated control system based on a pre-feeding coal control model, comprising the following steps:

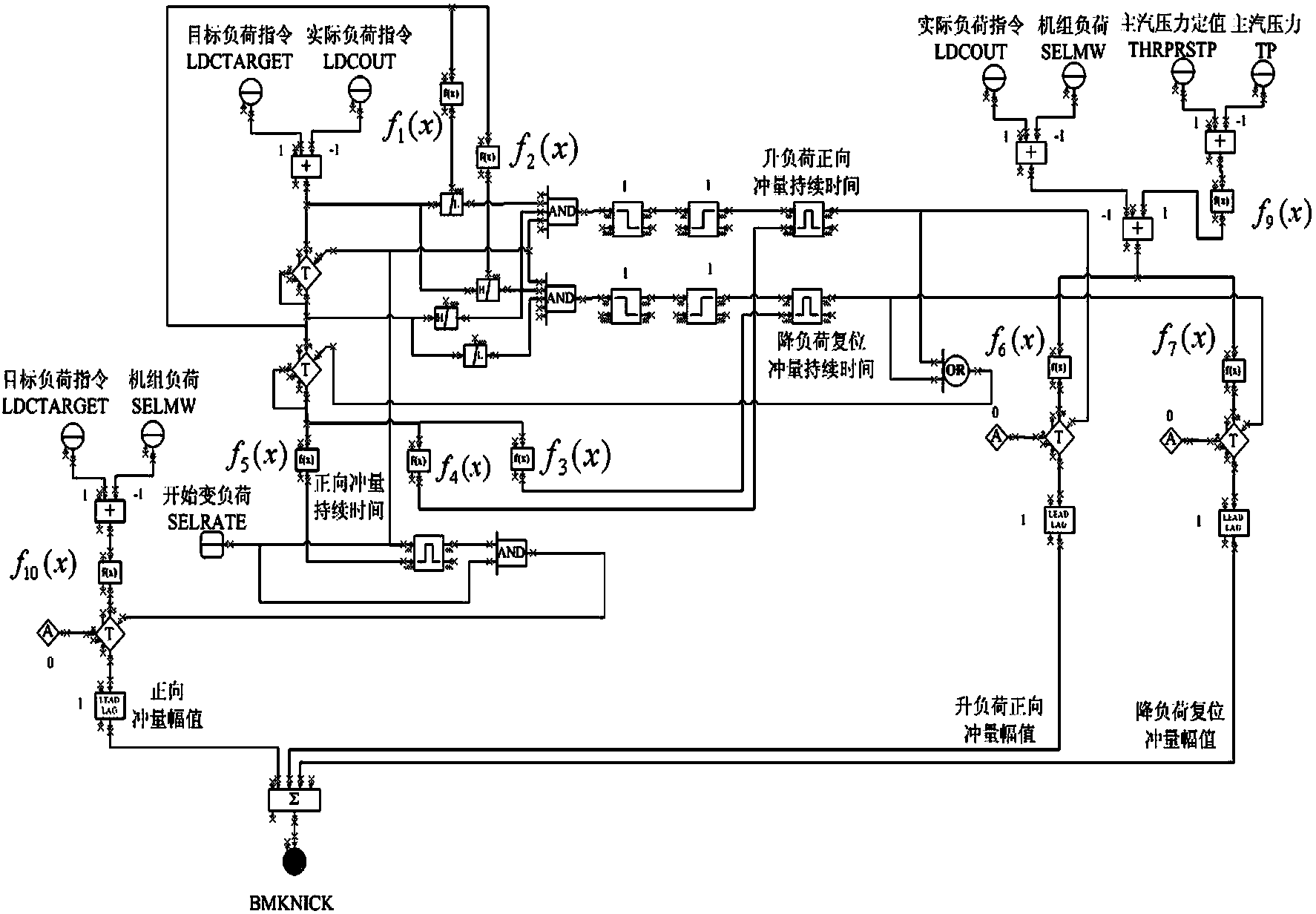

[0032] The first step: add the pre-feeding coal control loop interface to the logic configuration boiler main control loop of the original coordinated control system;

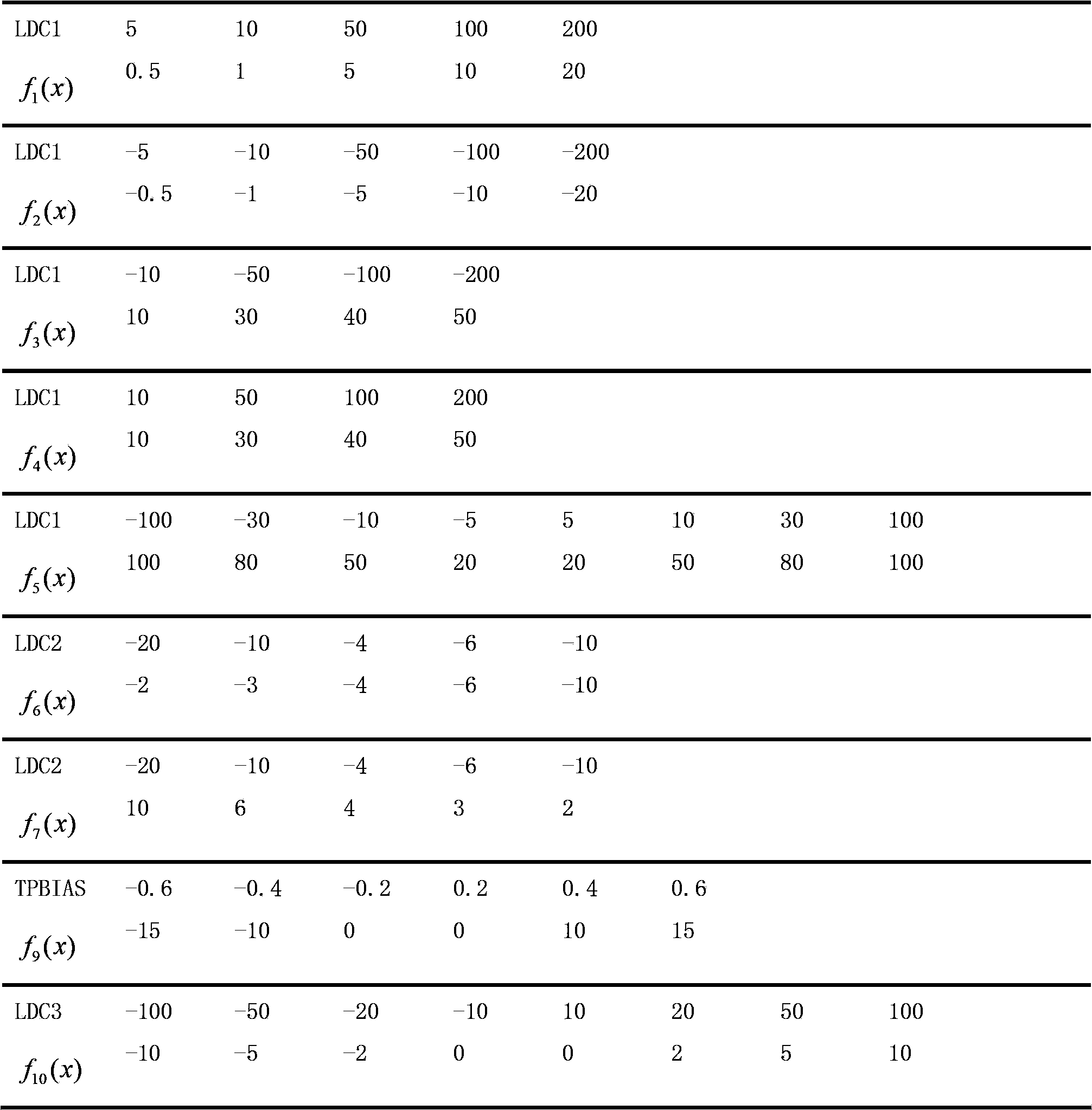

[0033] The second step: Carry out the logic configuration of the pre-feeding coal control loop, and introduce its output into the interface of the pre-feeding coal control loop as the feed-forward signal for boiler control;

[0034] The third step: add the main steam pressure internal model controller, and introduce its output into the main control circuit of the boiler as the input signal of the pressure circuit;

[0035] Step 4: Export historical data from the DCS historical station of the unit, and use computer software to assist in setting the parameters of the pre-feeding coal control model;

[0036] Step 5: Put the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com