Fluid loss monitoring device and method

A technology for monitoring device and fluid flow, used in gas/liquid distribution and storage, piping systems, mechanical equipment, etc., to solve problems such as inaccurate water flow measurement, water loss, and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

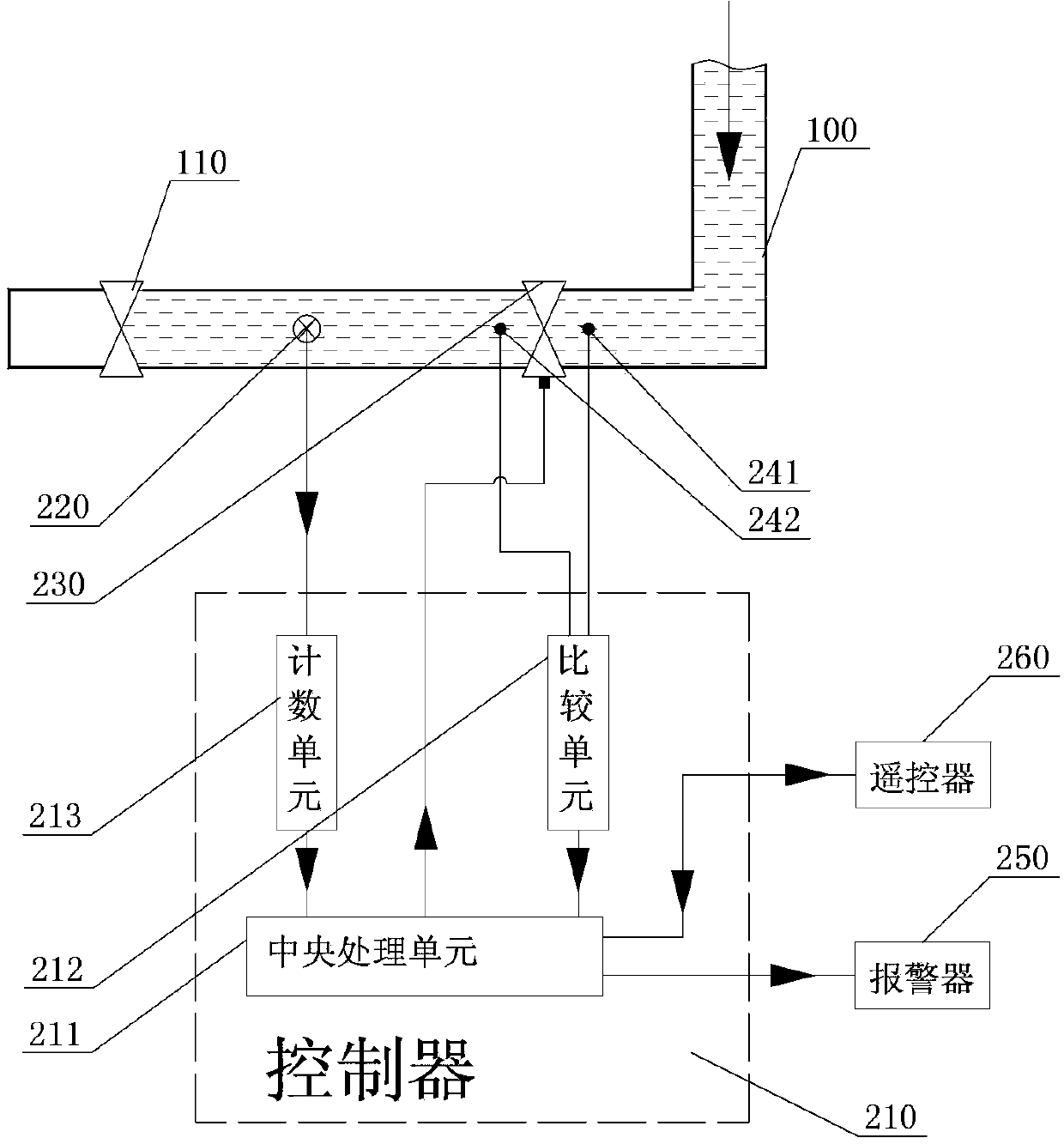

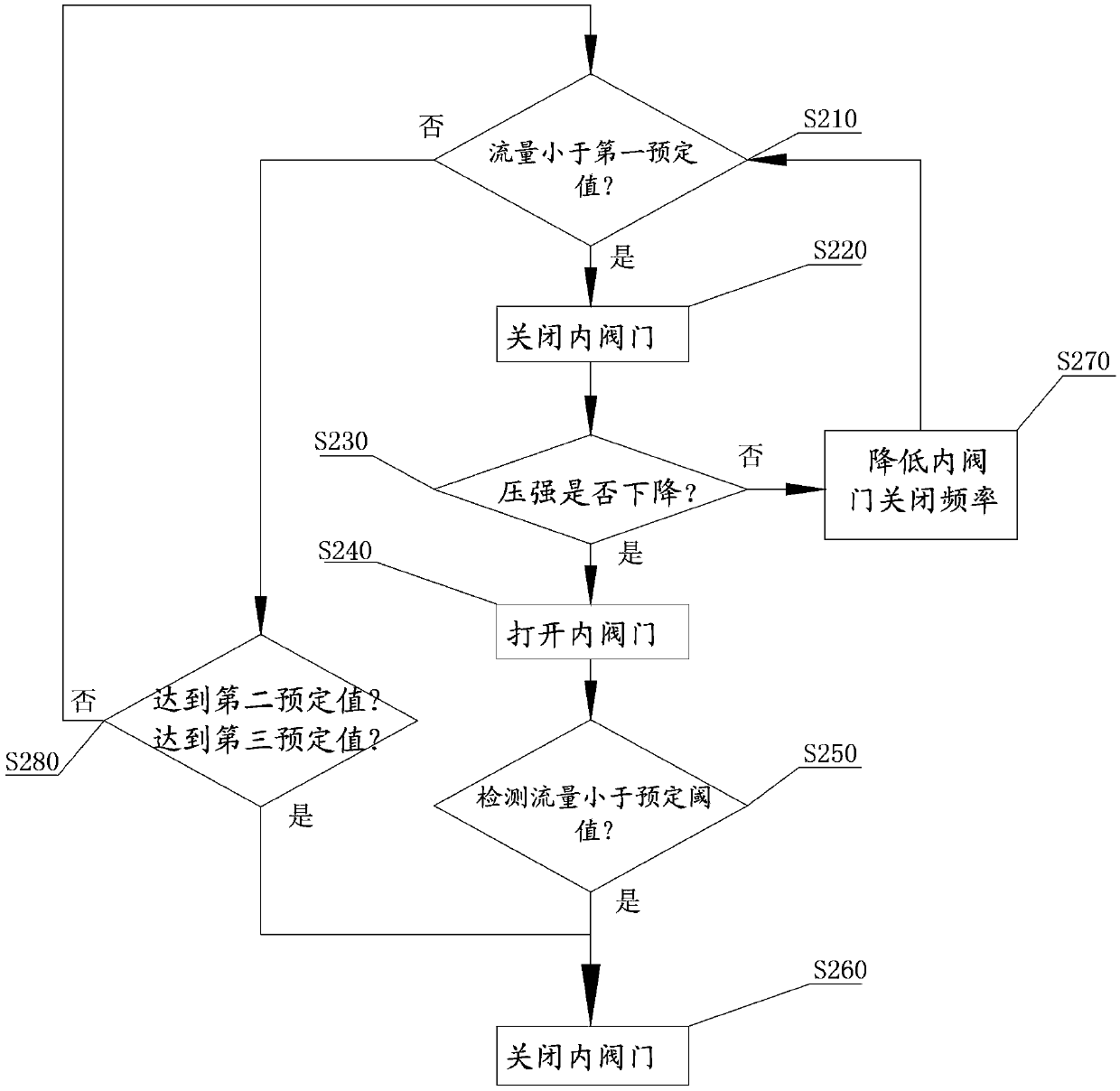

[0040] The core of the present invention is: by detecting the pressure of the fluid between the terminal valve and the inner valve, combined with the fluid flow, the accurate judgment and control of the pipeline state can be realized, and the quantitative judgment of the fluid flow can be converted into whether the pressure is reduced and the fluid flow rate is reduced. The qualitative judgment of whether the flow rate is less than a predetermined threshold can overcome the shortcomings of the existing quantitative detection technology and improve the accuracy of judgment.

[0041] The technical solution provided by the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not be regarded as limiting the technical content disclosed in the present invention.

[0042] It should be noted that in this document, the inner side refers to the side close to the fluid so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com