Device for purifying gas

A gas and intake pipeline technology, applied in the fields of inert gas compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of short utilization cycle, pause in the production process, low utilization rate of purified substances, etc. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

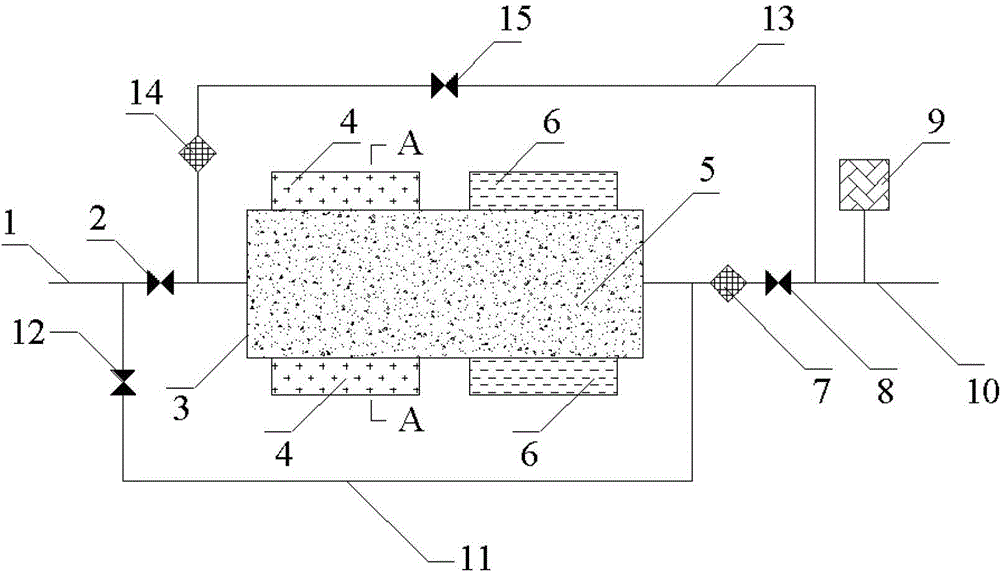

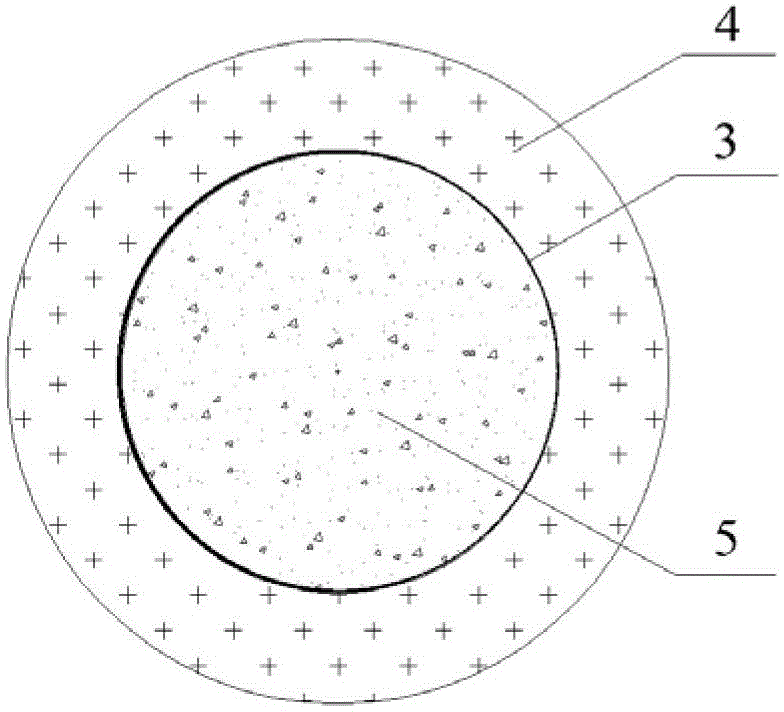

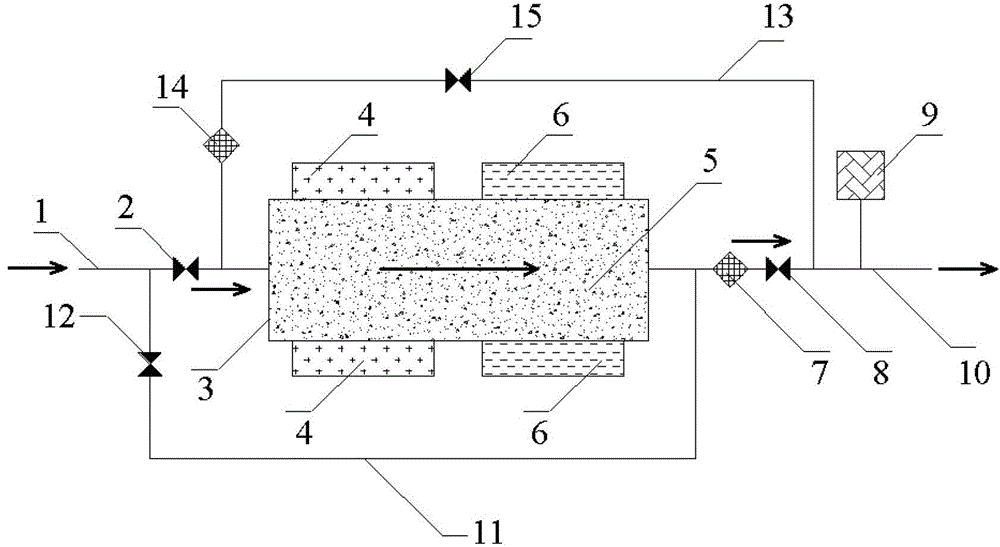

[0012] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 , this embodiment is a device for purifying gas, a device for purifying gas, which is composed of an intake pipeline 1, a first valve 2, a reactor shell 3, a heater 4, particulate matter 5, a cooler 6, a second A filter 7, a second valve 8, a hygrometer 9, an outlet pipeline 10, a first bypass 11, a third valve 12, a second bypass 13, a second filter 14 and a fourth valve 15, wherein, The reactor housing 3 is cylindrical, and the reactor housing 3 is filled with particulate matter 5 for purifying the gas. The lower bottom surface is communicated, a heater 4 is set on the side of the left half of the reactor shell 3, and a cooler 6 is set on the side of the right half of the reactor shell 3, the heater 4 and the cooler 6 can exchange positions, On the gas pipeline 1, from left to right, there are three-way joint I connected to the starting end of the first bypass 11, the first val...

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the particulate matter 5 is a mixture of calcium chips and ceramic particles. Others are the same as in the first embodiment.

[0018] The working mechanism of the purified gas that adopts the mixture of calcium chips and ceramic particles as the particulate matter 5 described in this embodiment is as follows: Process 1, the side of the left half of the reactor shell 3 is heated to the reactor shell by the heater 4 3. The calcium in the calcium chips in the left half of the interior evaporates. When the gas to be purified enters the reactor shell 3, it mixes with the calcium vapor. A part of the calcium vapor reacts with the impurities in the gas and becomes solid and deposits. The unreacted Part of the calcium vapor and the purified gas enter the right half of the reactor shell 3, and the side of the right half of the reactor shell 3 is cooled by the cooler 6, so that the unreacted part of th...

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of calcium chips and ceramic particles in the particulate matter 5 is 1:(0.2~5). Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com