Steel ball racking machine

A packing machine and steel ball technology, applied in the direction of packaging, transportation and packaging, and the type of packaged items, can solve the problems of high labor intensity and low efficiency, and achieve the effects of reducing labor intensity, huge economic benefits, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

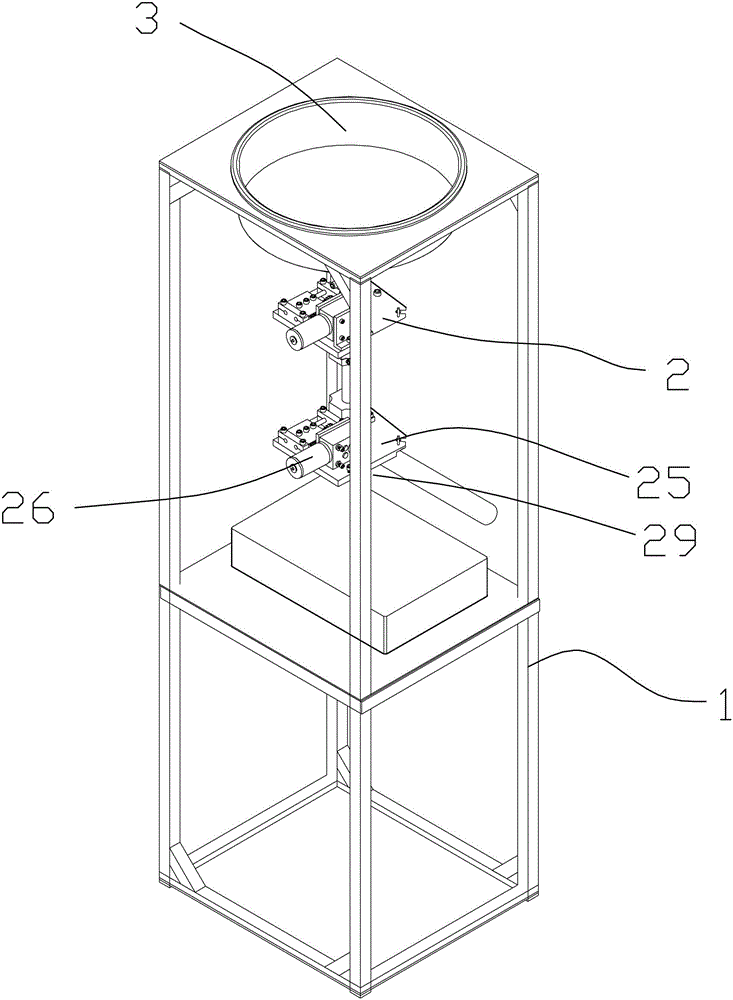

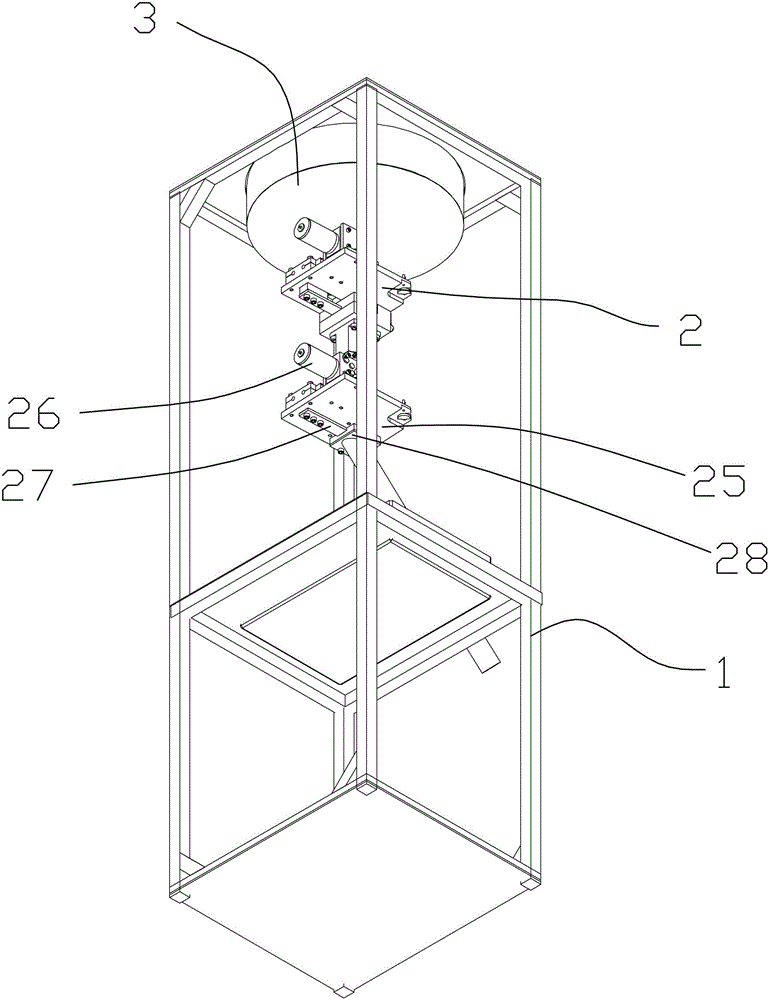

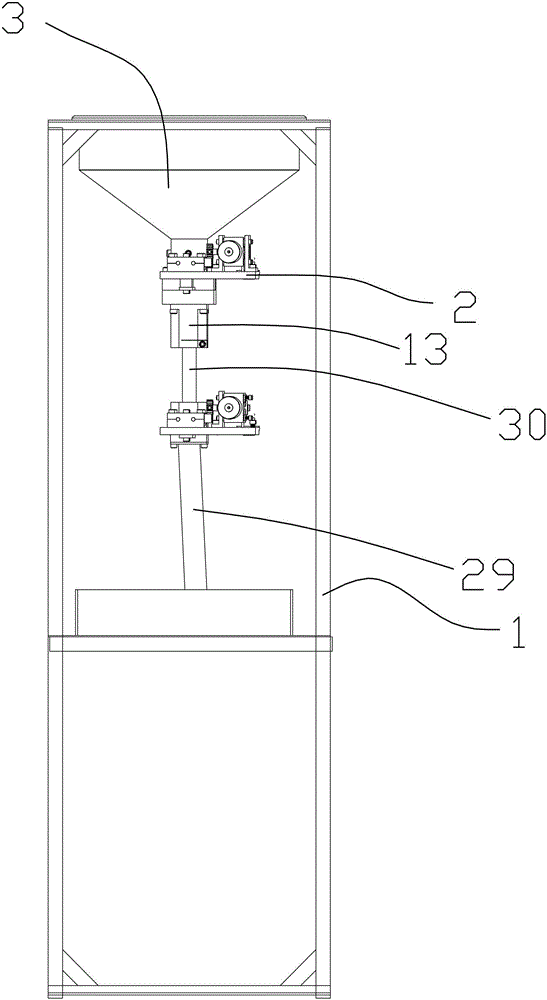

[0035] refer to Figure 1 to Figure 7 , the invention discloses a steel ball dispensing machine, comprising a frame 1 for supporting, a funnel 3 arranged on the frame 1, the funnel 3 is used to store steel balls to be sorted, and an upper valve is closed The mechanism includes a first support plate 2 arranged on the frame 1, and a first drive mechanism 5 is arranged on the first support plate 2. The first drive mechanism 5 adopts a common motor as a power source, and the first drive mechanism 5 is connected to There is a first transmission mechanism, the first transmission mechanism is connected with the first push mechanism, the upper valve 6 is connected with the first push mechanism, and the lower valve closing mechanism includes the second supporting plate 25 arranged on the frame 1, the second The support plate 25 is provided with a second drive mechanism 26, the second drive mechanism 26 is connected with a second transmission mechanism, the second transmission mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com