Electromechanical folding carton gluer

A folder-gluer, electromechanical technology, applied in the direction of container manufacturing machinery, box making operations, paper/cardboard containers, etc., to achieve good economic benefits, compact structure, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Several embodiments of the present invention are discussed in detail below with reference to the accompanying drawings.

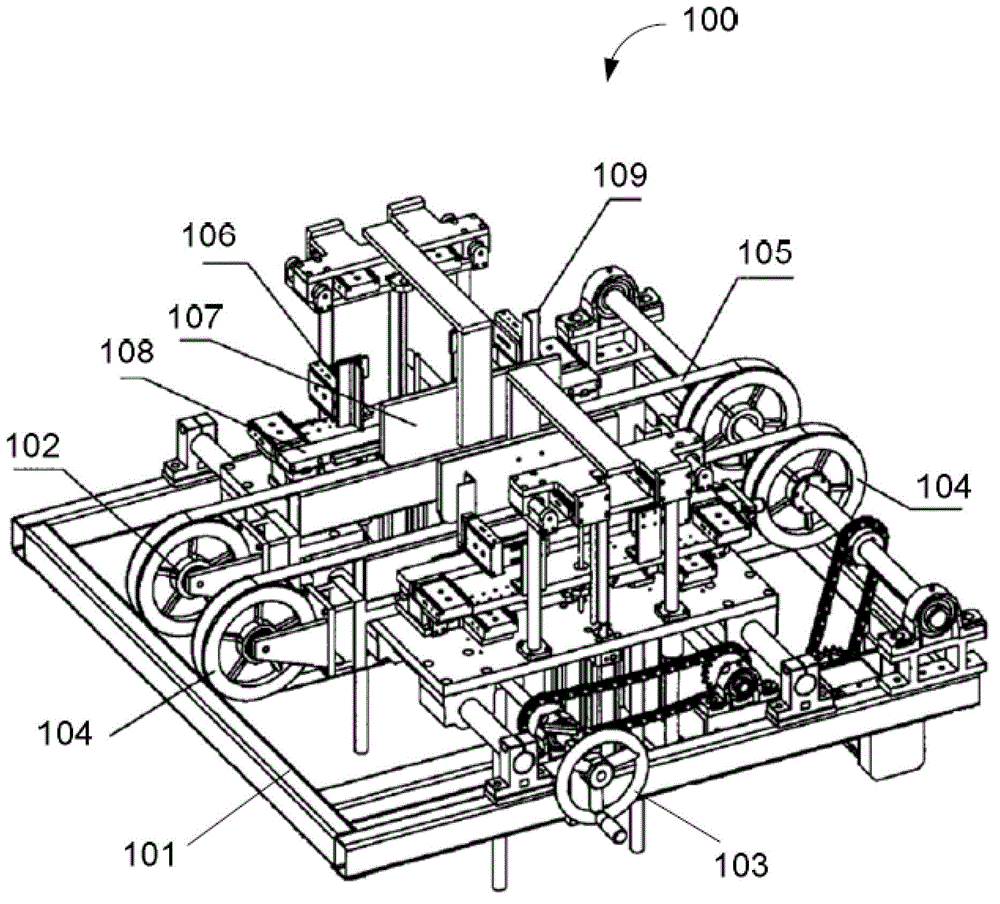

[0019] figure 1 It schematically shows the main structure of the electromechanical folder-gluer of the present invention. As shown in the figure, the electromechanical folder-gluer 100 of the present invention mainly includes: a rectangular frame 101, a hand-operated conveying mechanism 102, a handle 103, a roller 104, a conveyor belt 105, a glue roller 106, a pressure plate 107, and a swing arm 108 and a photoelectric converter 109.

[0020] The hand-operated conveying mechanism 102 is arranged on the rectangular frame 101, the handle 103 of the said hand-operated conveying mechanism 102 is located outside the said rectangular frame 101 and the front and rear two groups of rollers 104 of said hand-operated conveying mechanism 102 drive the conveying The belt 105 is conveyed on a plane parallel to the surface of the rectangular frame 101 .

[0021...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com