Technique for cooling deep mining area by using ground temperature of shallow goaf and waste roadway

A goaf and deep technology, which is used in mine/tunnel ventilation, mining equipment, earth-moving drilling, etc., can solve the problem of pre-cooling air volume, wind resistance adjustment, difficulty in air flow adjustment, and heat exchange area between wind flow and surrounding rock in the goaf. Small problems such as optimizing the ventilation system management mode, improving the ventilation management level, and consolidating the effect of cooling and pre-cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further describe the present invention, the technology for cooling deep mining areas by using the ground temperature of shallow mined-out areas and waste roadways of the present invention will be further described in detail in conjunction with the accompanying drawings and examples below.

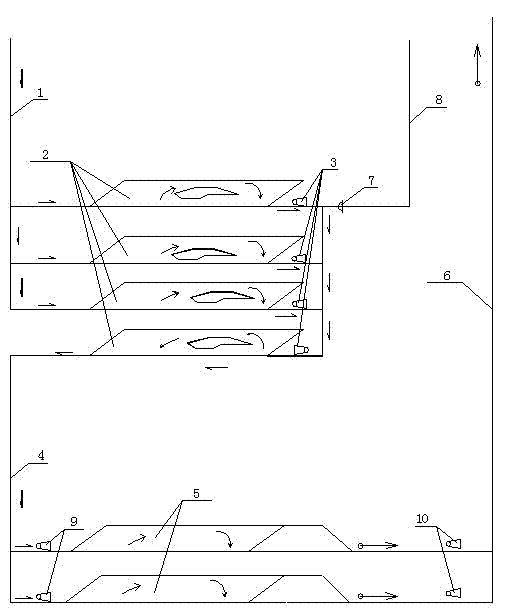

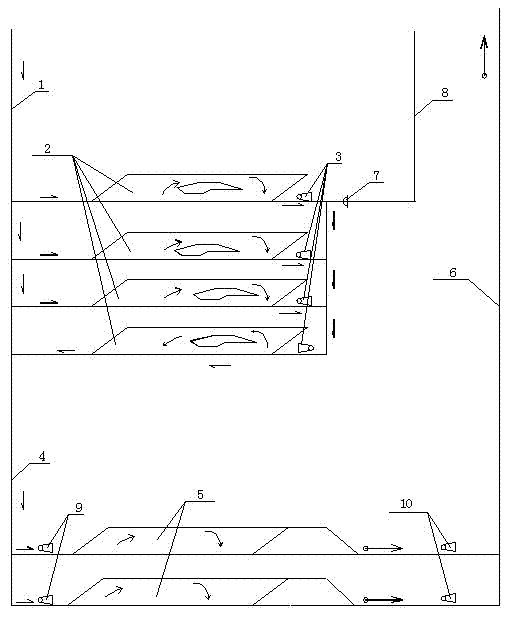

[0027] Depend on figure 1 The schematic diagram of the deep mining area cooling system using the shallow goaf and waste roadway ground temperature to cool the deep mining area with all the air flow precooling of the deep air inlet source is shown. The shallow air intake shaft 1 goes down, and under the negative pressure of the pre-cooling fan 3 in the upper (n-1) shallow gobs and the middle section where the waste roadway 2 is located (the pre-cooling fan is pulled out), the mine All the fresh air flow into the shallow goaf and the abandoned roadway 2 is introduced into the shallow mined-out area and the low-temperature rock mass of the abandoned roadway 2 for heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com