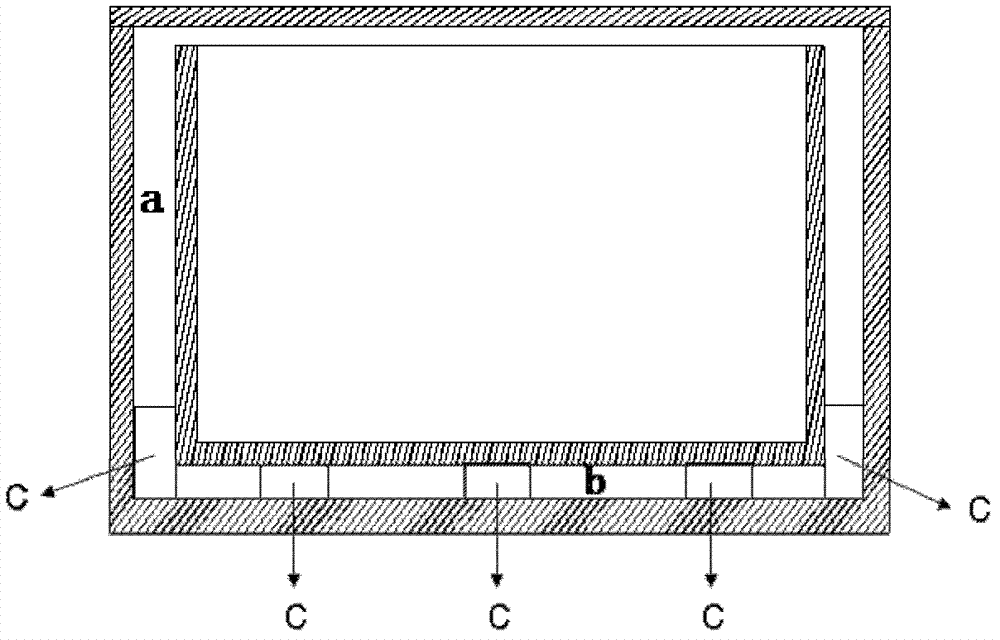

Ventilating moisture-proof container

A container and container cover technology, which is applied in the direction of anti-rot containers, containers, transportation and packaging, etc., and can solve the problems of short storage period, easy to be affected by moisture or infested with insects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

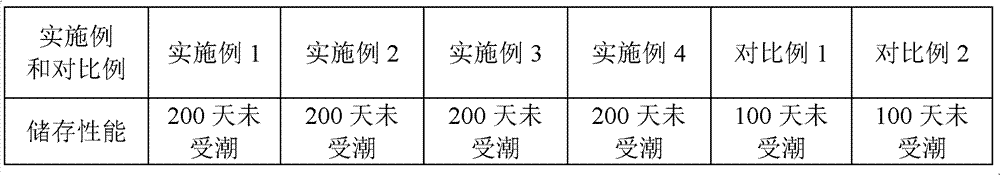

Examples

preparation Embodiment 1

[0053] This example is used to illustrate the preparation of the film-coated first aggregate particles provided by the present invention.

[0054] Heat 100 grams of quartz sand with an average particle diameter of 0.25mm to 50°C, then add 5 grams of liquid polyvinyl alcohol tert-butyraldehyde modified epoxy resin, stir well, then add 1 gram of polyamide curing agent, and stir evenly. The epoxy resin is coated on the surface of the quartz sand; then, cooled to room temperature, crushed and sieved to obtain the coated first aggregate particles, and calculated by weighing method, the total weight of the coated first aggregate particles As a basis, the content of the hydrophobic substance coating layer was 6% by weight.

preparation Embodiment 2

[0056] This example is used to illustrate the preparation of the film-coated first aggregate particles provided by the present invention.

[0057] Heat 100 grams of ceramsite with an average particle diameter of 0.23mm to 50°C, then add 4 grams of silicone resin, stir thoroughly, then add 0.5 grams of dibutyltin dilaurate curing agent, and stir evenly to make the silicone resin Cover the surface of the quartz sand particles; then, cool to room temperature, crush and sieve to obtain the first aggregate particles of the coating, and calculate by weighing method, based on the total weight of the first aggregate particles of the coating, The content of the hydrophobic substance coating layer was 4.3% by weight.

preparation Embodiment 3

[0059] This example is used to illustrate the preparation of the film-coated first aggregate particles provided by the present invention.

[0060] Mix 50 grams of quartz sand with an average particle diameter of 0.25 mm and 50 grams of glass microspheres with an average particle diameter of 0.31 mm and heat to 50 ° C. After that, add 2 grams of liquid polyurethane resin, stir well, and then add TDI trimer 0.2 grams of body curing agent, stirred evenly, so that the polyurethane resin is coated on the surface of quartz sand and glass beads; then, cooled to room temperature, crushed and sieved to obtain the first aggregate particles coated with the coating, and calculated by weighing method , based on the total weight of the film-coated first aggregate particles, the content of the coating layer of hydrophobic substances is 2.2% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com