Method and device for operating actuator with brushless electric motor

一种电动马达、促动器的技术,应用在阀装置、仪器、电气控制等方向,能够解决耗费布线、促动器昂贵、耗费等问题,达到避免额外费用、避免电刷火花、小能量需求的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] FIG. 1 shows an actuator system 1 with an actuator 2 which is triggered by a controller 3 .

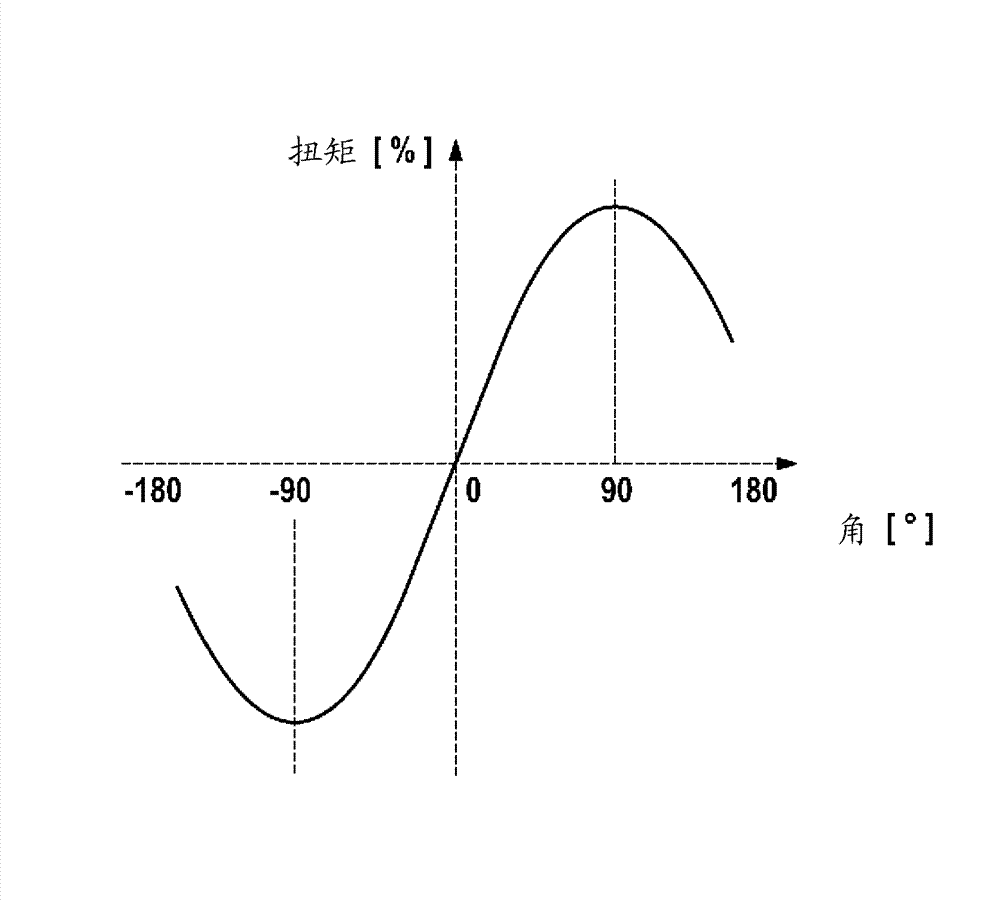

[0057] The actuator 2 comprises an electric drive 4 which has an electronically commutated, ie brushless, electric motor, for example a synchronous electric motor, an asynchronous electric motor or the like. The driver 4 has an output shaft, which is coupled with the transmission mechanism 5 . The transmission 5 is also coupled to an actuator 6 . The actuator 6 triggered by the controller 3 should move or adjust into a predetermined position or orientation.

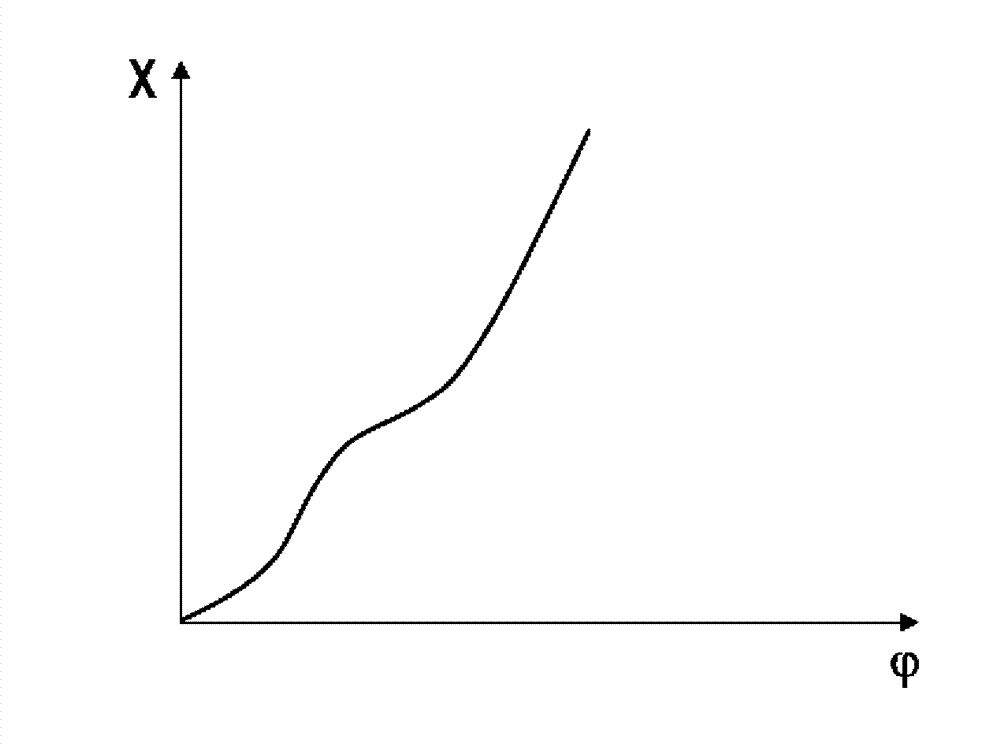

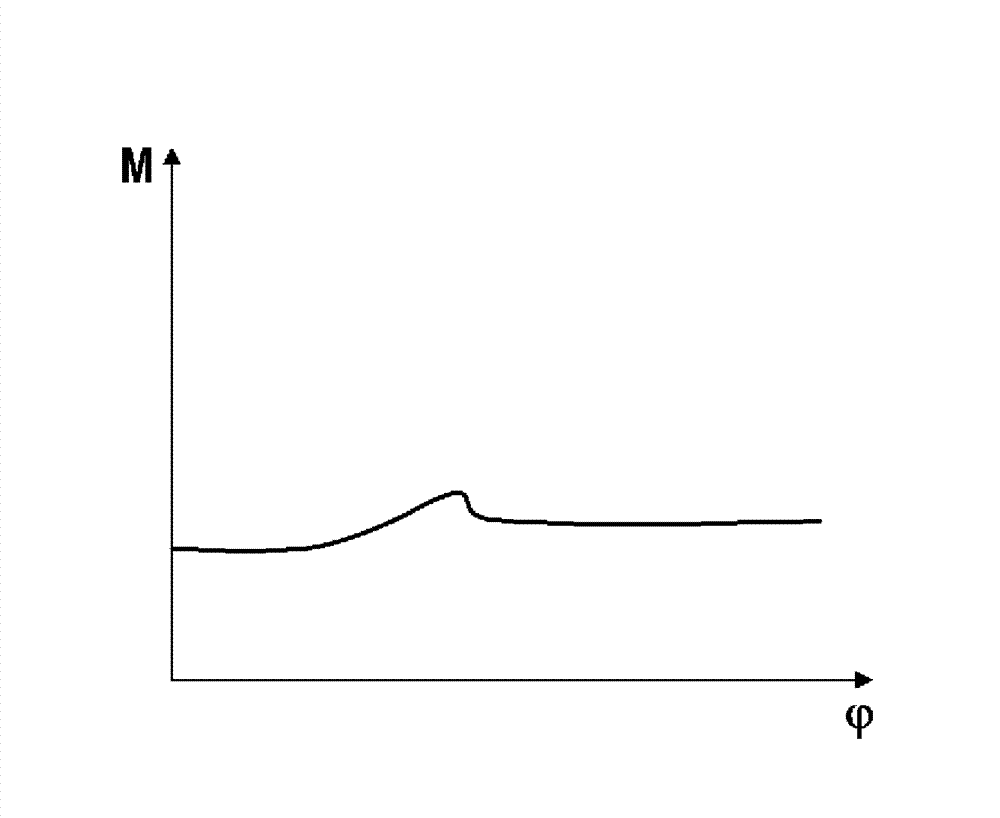

[0058] A position sensor 7 is arranged on the actuator 6 or, alternatively, on the transmission 5 . The adjustment movement or the position of the actuator 6 can be detected by means of the position sensor 7 . A statement about the detected position of the actuator 6 is forwarded to the controller 3 . The position sensor 7 can have, for example, a GMR sensor (GMR: giant magnetoresistance), a Hall sensor or the like. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com