Digital differential control system for gas-liquid flow

A digital differential and control system technology, applied in the flow control of electric devices, etc., can solve the problems of low fuel consumption areas, the angle of valve core rotation cannot be accurately controlled, and cannot be adjusted in place in one step, so as to achieve precise adjustment and eliminate fuel consumption. The effect of high consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

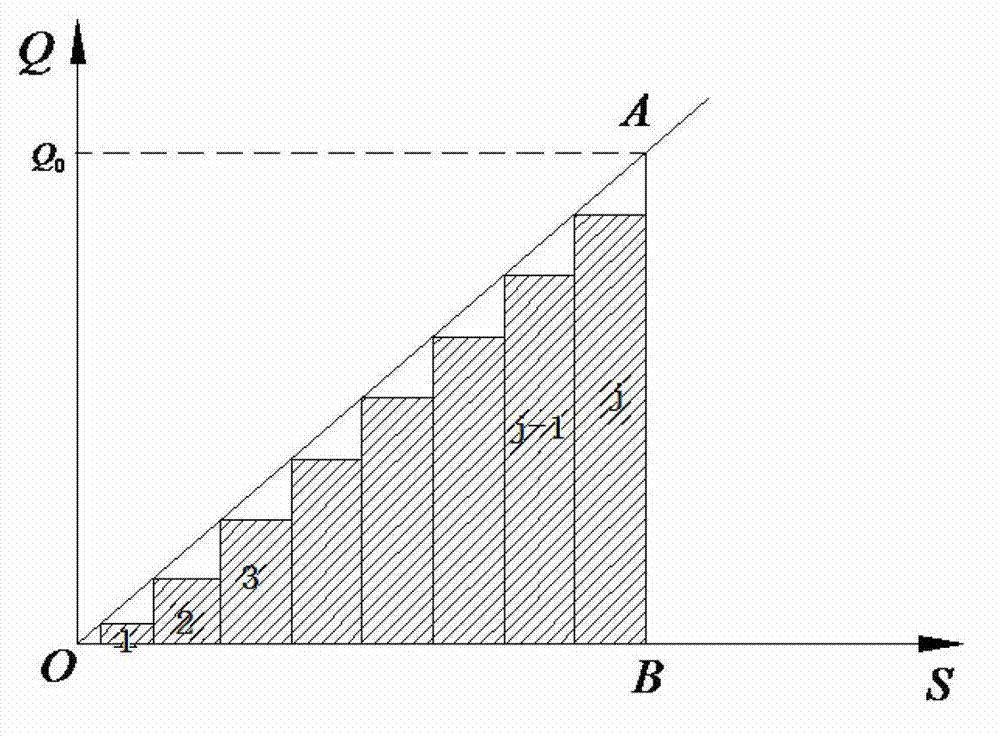

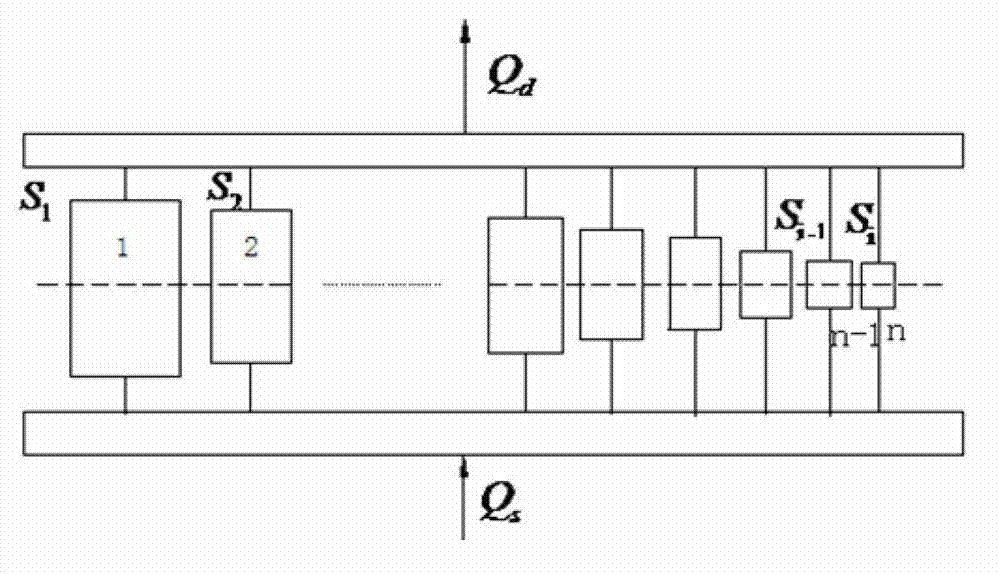

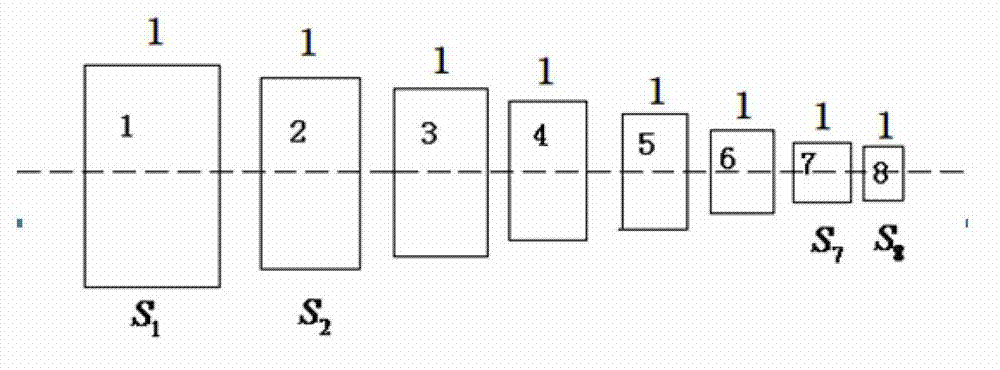

[0024] The gas-liquid flow digital differential control system for internal combustion engines, gas boilers, etc. provided by the present invention can completely overcome the shortcomings of traditional stepping motor adjustment, and achieve precise adjustment in place at one time. The principle of the gas-liquid flow differential control system consists of figure 1 Indicates that the abscissa S in the figure is the flow area of the valve, and the ordinate Q is the gas-liquid flow rate. At a certain set flow rate Q 0 Below, the total flow area of the valve is represented by the triangle area OAB, and the total flow area after the flow digital differential adjustment control is represented by the shaded area in the figure, that is, the triangle area is replaced by the rectangular area of several valves. If very accurate Adjustment, you can set multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com