Method for predicting coke quality through nonlinear optimization coal blending based on coal rock vitrinite total reflectance

A technology of coke quality and total reflectance, applied in the field of coal chemical industry, can solve the problems of no algorithm, weak generalization ability, predicting the difference of coke mechanical strength and thermal state performance, etc., to avoid overfitting and improve generalization ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in more detail below by means of embodiments in conjunction with the accompanying drawings.

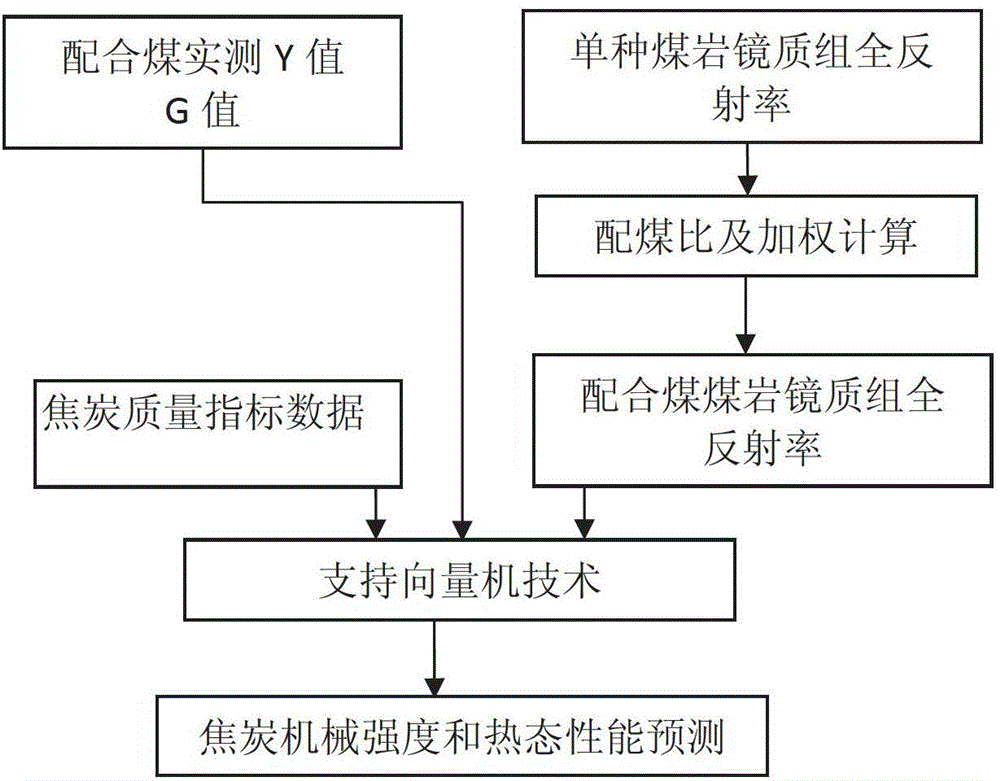

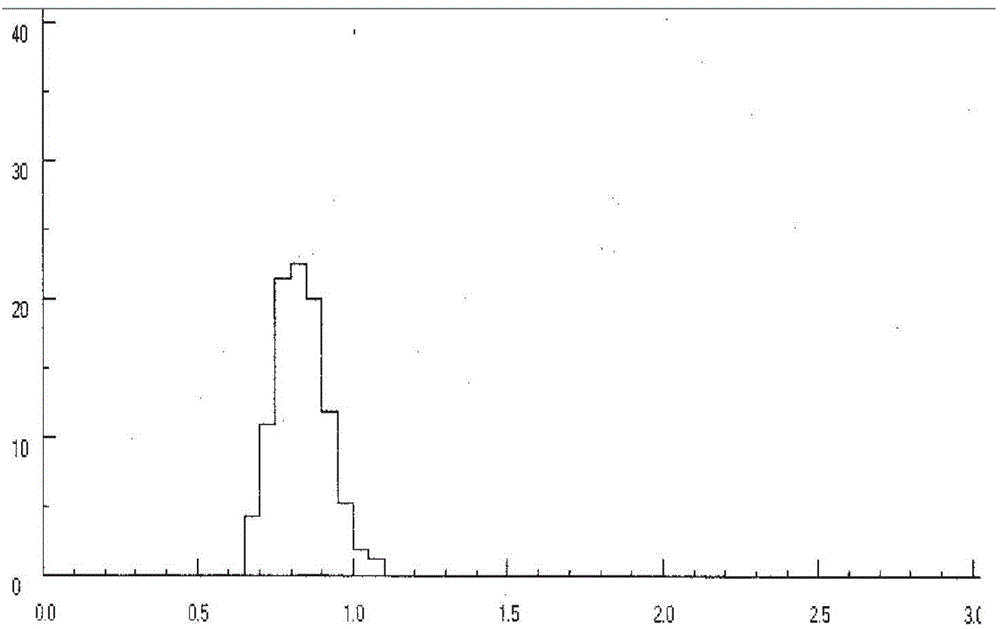

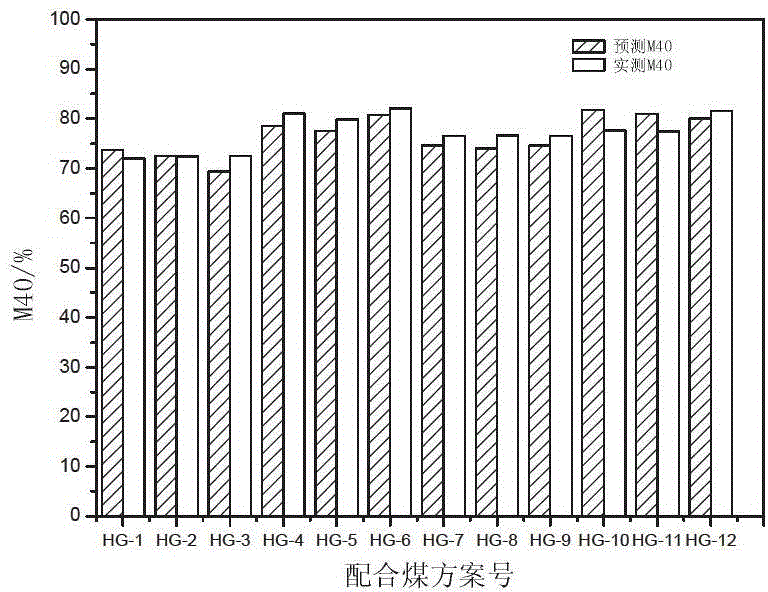

[0070] The present invention predicts the quality index of coke through the technology of support vector machine, and the cohesiveness index of coal quality that will be tested and analyzed with coking coal includes two factors of colloidal layer index and cohesive index, both input parameters; coal rock index, including The reflectance of all components of the vitrinite and the active-inert ratio of the microcomponents are two factors as independent variables, which are input parameters, and the mechanical strength of coke M 40 , M 10 And thermal performance CRI, CSR as output parameters, through the training of support vector machine, get the nonlinear relationship between input parameters and output parameters. The colloidal layer index, cohesion index, vitrinite total component reflectance and microscopic component activity-inert rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com