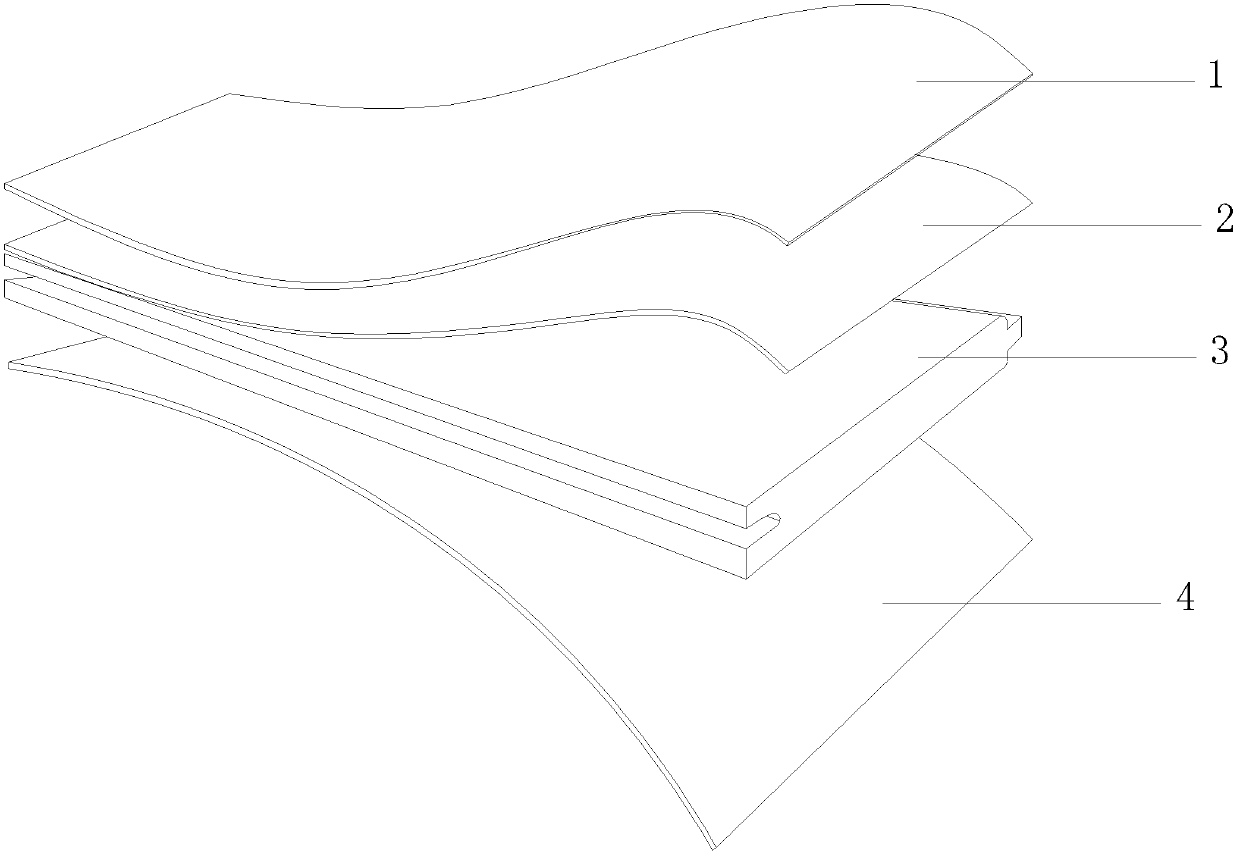

Large-area solid wood composite block floor as well as production method and installation method thereof

A solid wood composite, large-area technology, applied in the production and installation of large-area solid wood composite parquet floors, can solve the problems of different appearance gaps, harsh installation environments, and loose combination, etc., to improve the comprehensive utilization rate and surface three-dimensional effect The effect of strong, improved installation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0085] Sanding back: Sanding is carried out on the forming linear sand machine, and the semi-finished solid wood composite floor slab is sanded with a fixed thickness. The function of the fixed-thickness sanding is to prevent partial sanding or partial sanding due to uneven thickness of the slab in subsequent production. The situation where the sand is not available.

[0086] Sand surface: use oil sand machine for sanding on the paint line, sand leakage is not allowed, and offset printing and crushing are not allowed on the panel. Can not be sanded through, no sanding stripes. For slight sand leakage, use artificial hand sand, and the hand sand must be in place.

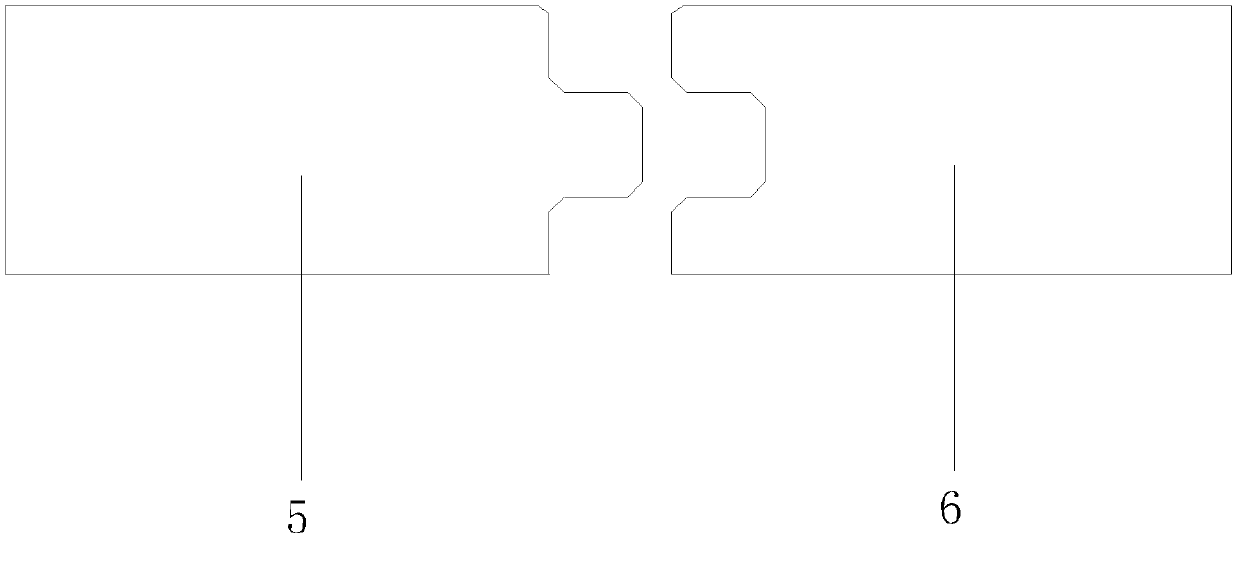

[0087] Step six, tongue and groove:

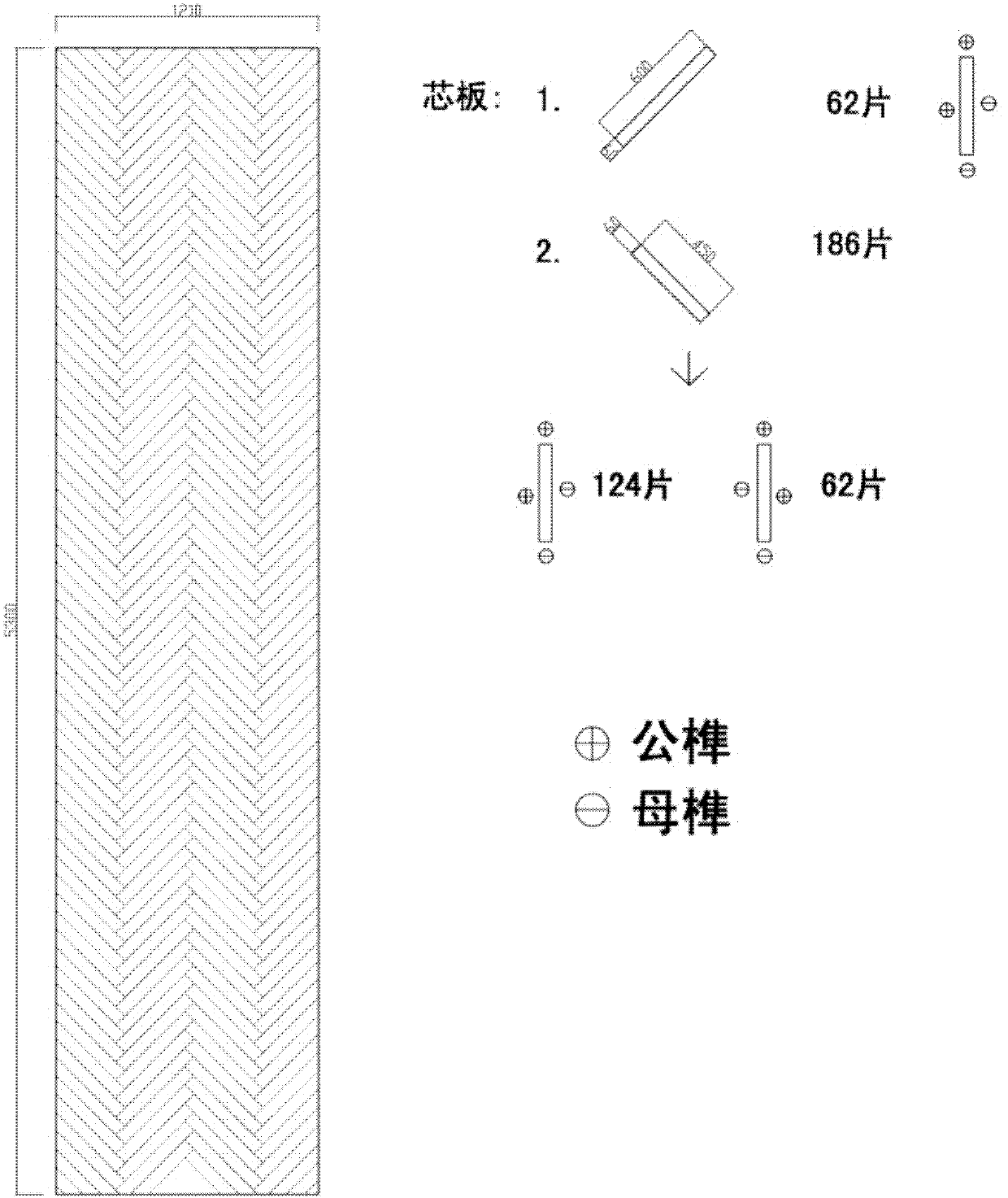

[0088] The process of cutting out the male tenons and female grooves of the parquet floor slabs that have reached the curing period.

[0089] The thickness of the floor is different, and the tongue and groove are different: 15mm thick floor: upper: 5.1mm, middle: 5.7mm, lower:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com