Filter-type automatic water compensating pot

An automatic water replenishment and filtering technology, which is applied in the direction of water saving, water supply equipment, water supply pool configuration, etc., can solve the problems of affecting the normal supply of tap water, affecting the life of residents, and damaging water pumps, so as to ensure timely and normal supply and protect people from damage and avoid economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

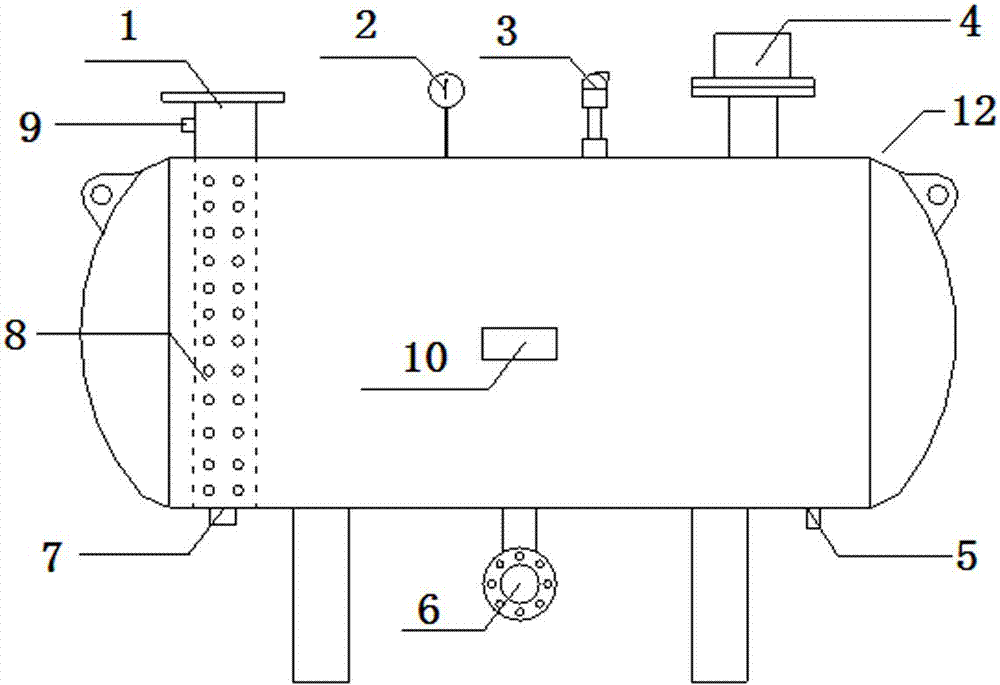

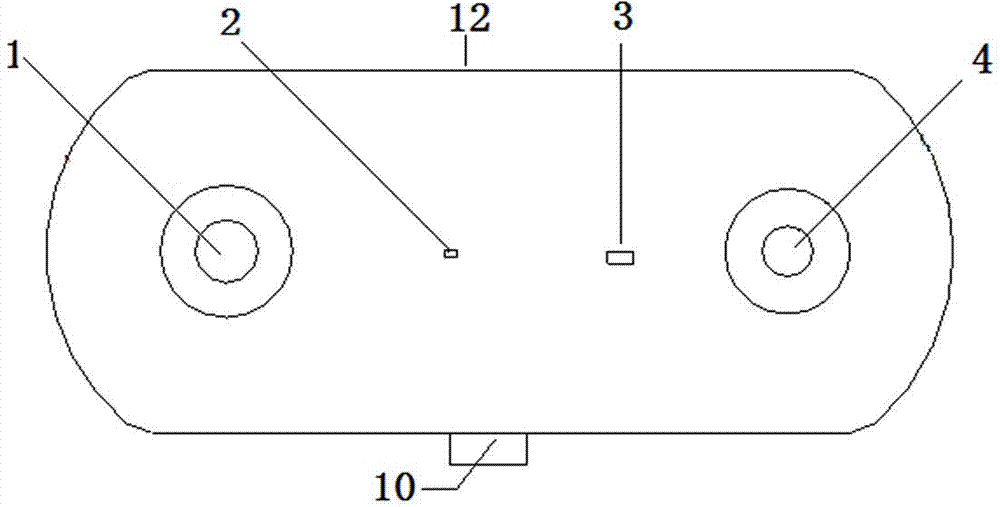

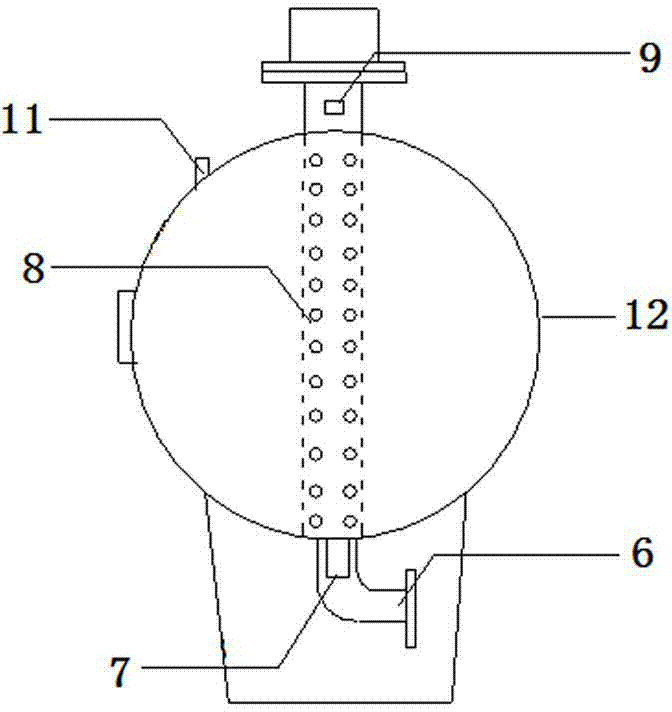

[0017] Such as figure 1 , figure 2 and image 3 The filter type automatic replenishment tank shown includes a regulating tank 12, a water inlet 1, a pressure gauge 2, a liquid level controller 3, a negative pressure eliminator 4, an emergency air intake valve 5, a water outlet 6, a water inlet pressure sensor 9, Water source filter device 8, sewage outlet 7 that can be opened or closed, sterilizer interface 11, sign 10, regulating tank 12 is a fully enclosed structure, water inlet 1, pressure gauge 2, liquid level controller 3 and negative pressure eliminator 4 are set Above the adjustment tank 12, the emergency air inlet valve 5 and the water outlet 6 are arranged at the bottom of the adjustment tank 12, the water inlet pressure sensor 9 is arranged on one side of the water inlet 1, and the sterilizer interface 11 is arranged obliquely above the adjustment tank 12 , the label 10 is located in front of the regulating tank 12, the upper end of the water inlet 1 is connected ...

Embodiment 2

[0019] A filter type automatic water replenishment tank, including a regulating tank, a water inlet, a pressure gauge, a liquid level controller, a negative pressure eliminator, an emergency air intake valve, a water outlet, a water inlet pressure sensor, a water source filtering device, and an openable or closed The sewage outlet, sterilizer interface, sign, and the regulating tank are fully enclosed. The water inlet, pressure gauge, liquid level controller and negative pressure eliminator are set above the regulating tank, and the emergency air inlet valve and water outlet are set on the regulating tank. At the bottom, the water inlet pressure sensor is set on the side of the water inlet, the sterilizer interface is set obliquely above the regulating tank, the sign is located in front of the regulating tank, the upper end of the water inlet is connected to the municipal tap water pipe, and the water source filtering device is set on the The square column-shaped pipeline struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com