Automatic stacking device of C type steel and stacking device

A technology of automatic stacking and C-shaped steel, which is applied in the stacking, transportation and packaging of objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

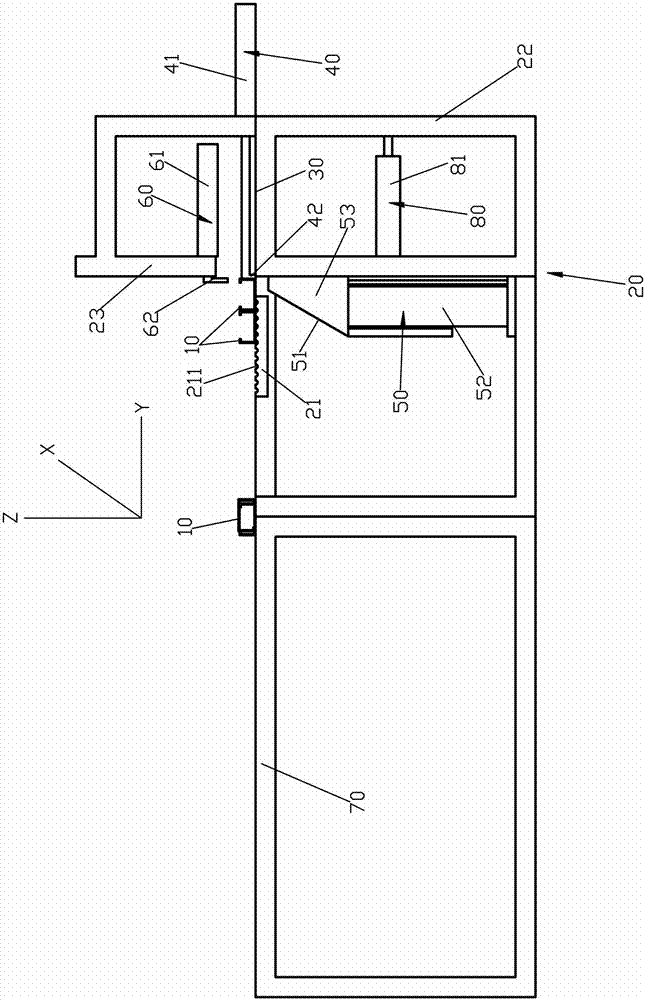

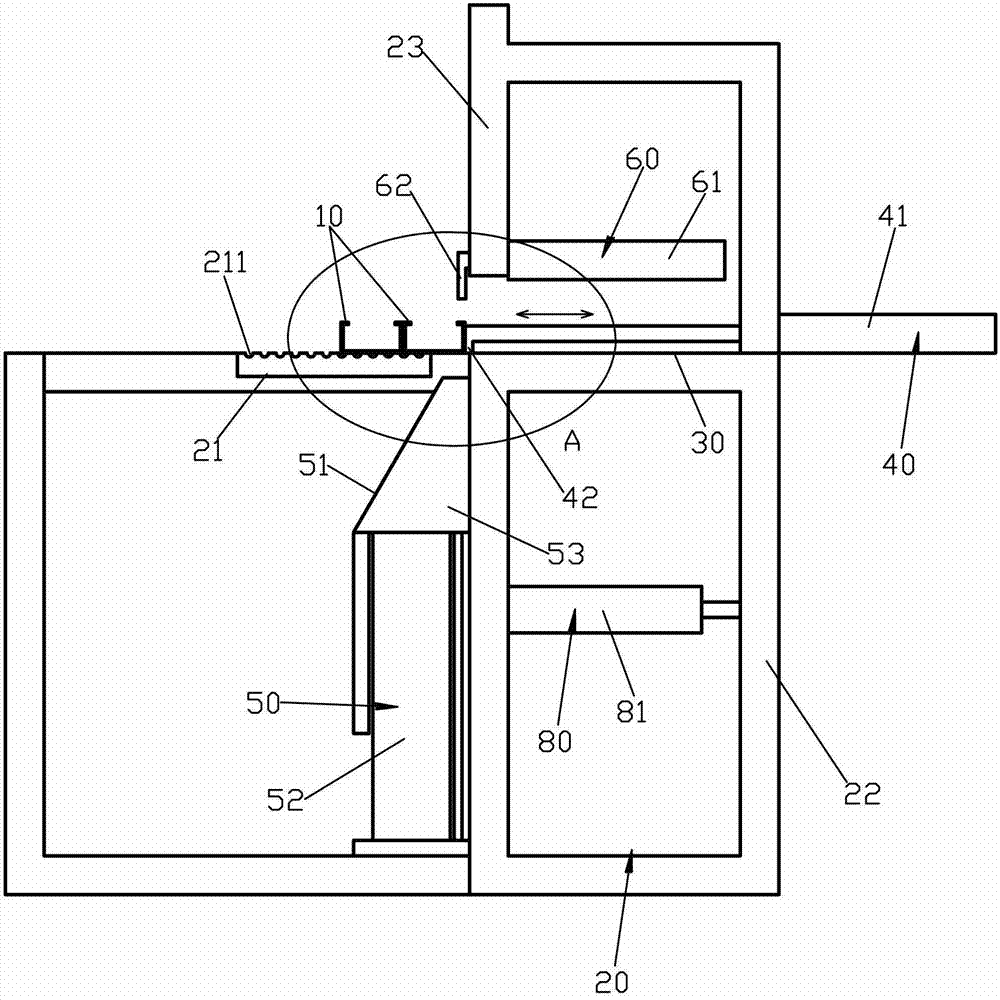

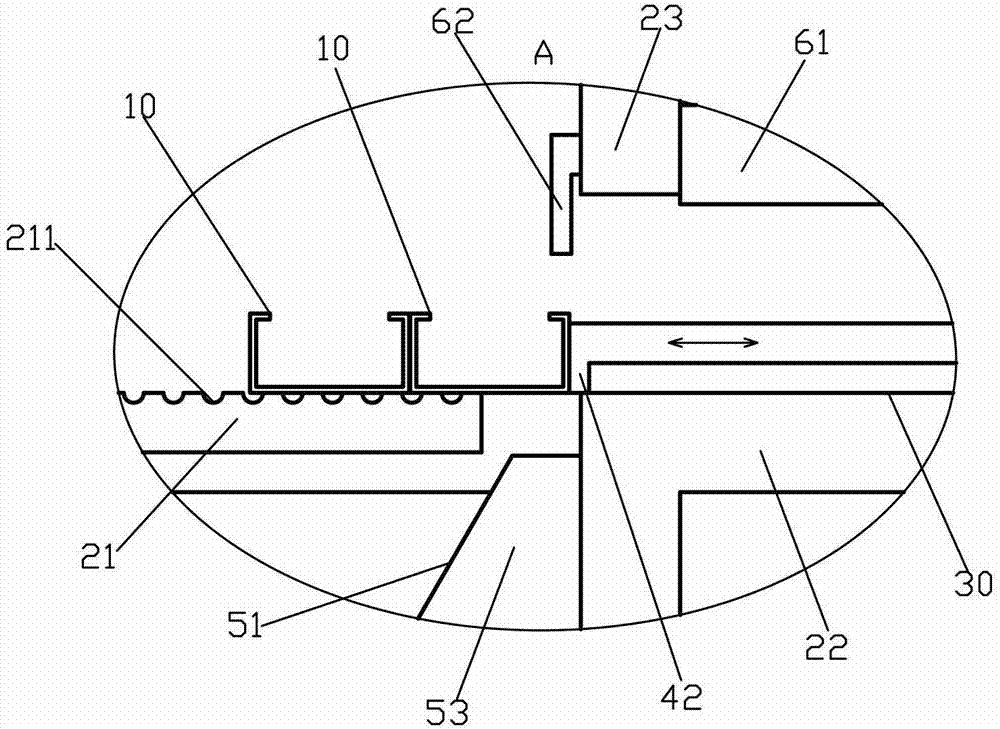

[0044] C-shaped steel automatic stacking equipment, please refer to Figure 1 to Figure 10 , including the machine base 20, the X-direction conveying mechanism 30, the first Y-direction pushing mechanism 40, the stacking mechanism, the stacking platform 70 and the third Y-direction pushing mechanism 80. The C-shaped steel 10 includes a bottom plate and two side plates respectively fixed on two sides of the bottom plate.

[0045] The machine base 20 is provided with a supporting platform 21 . The table surface of the support platform 21 is provided with a plurality of grooves 211 along the X direction arranged at regular intervals along the Y direction, and the support platform 21 is provided with a plurality of through grooves along the Y direction arranged at intervals along the X direction. The base 20 includes a base 22, a first fixed frame and a second fixed frame 23, the first fixed frame is arranged on the first side of the base 22, and the second fixed frame 23 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com