Four-dimensional sewage treatment tank sludge scrapping mechanism

A sewage treatment tank, four-dimensional technology, applied in the direction of chemical instruments and methods, separation methods, sedimentation separation, etc., can solve the problems of high cost, many components of the mud scraping device, difficult operation, etc., and achieve simple structure and good mud scraping effect , The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

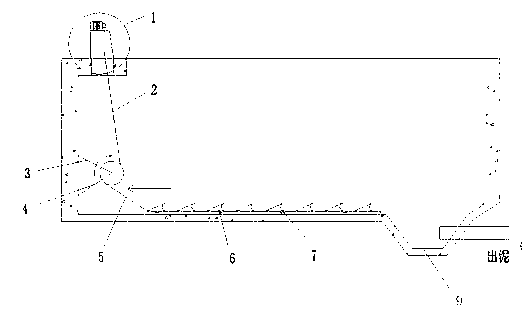

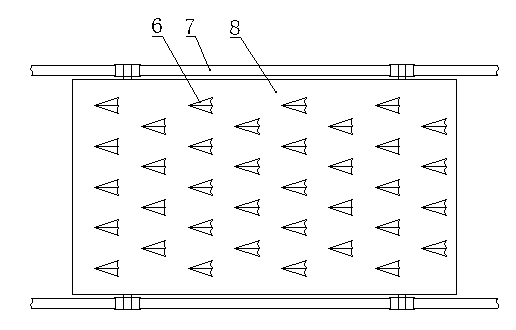

[0010] Such as figure 1 As shown, the hydraulic press 1, the hydraulic rod 2, the crankshaft 3, the support rod 4, the connecting rod 5, the scraper 6, the track 7, the inertial push plate 8, and the mud trough 9.

[0011] The inertial push plate 8 is arranged at the bottom of the sewage treatment tank, one end of the inertial push plate 8 is connected to the reciprocating drive mechanism, and the other end is adjacent to the mud outlet 9 at the bottom of the pond.

[0012] The inertial push plate 8 basically covers the bottom of the pool, but the two ends are at a certain distance from the pool wall, so as to be able to smoothly realize left and right reciprocating movement driven by the reciprocating drive mechanism. The two ends of the inertial push plate 8 are installed on the track 7 at the bottom of the pool. The track 7 includes a guide rail and guide wheels. The guide rail is fixed to the bottom of the pool. The guide wheels are installed on both sides of the inertial push p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com