Valve unit for a coating system

A valve unit, paint technology, applied in electrostatic spraying device, thin material processing, friction discharge spraying, etc., can solve problems such as unsatisfactory material resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

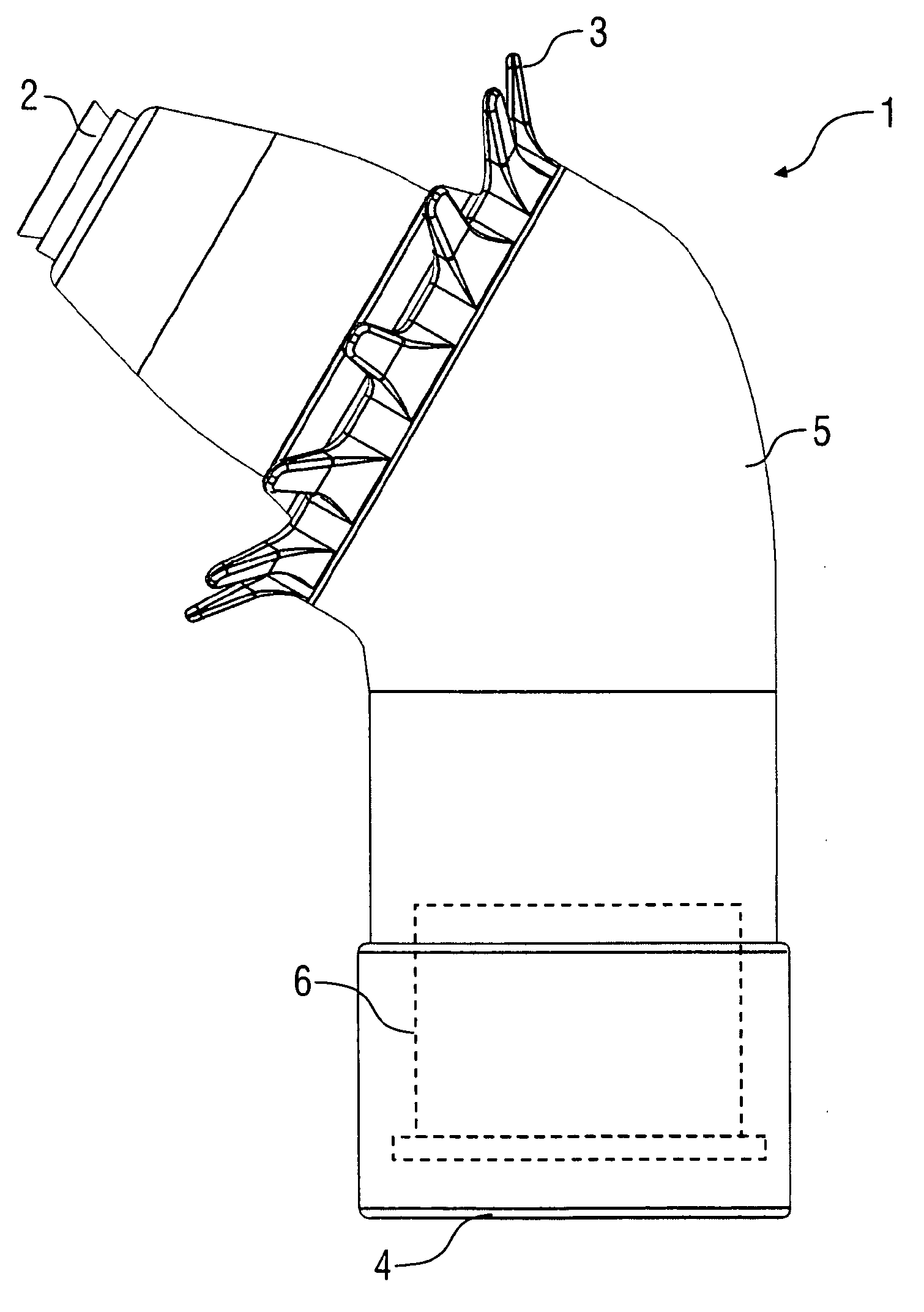

[0039] figure 1 A side view of a rotary atomizer 1 according to the invention is shown, which can be used, for example, for painting motor vehicle body parts. The rotary atomizer 1 has a rotary bell cup 2 as injection element, which is driven by a turbine.

[0040] In addition, the rotary atomizer 1 has an outer charging ring 3 in order to electrostatically charge the sprayed application agent so that the application agent deposits better on electrically grounded components.

[0041] As is known from the prior art, the rotary atomizer 1 can be fixed on a connecting flange 4 on the arm shaft of a multi-axis painting robot.

[0042] Furthermore, the rotary atomizer 1 has a housing 5 in which a valve unit 6 according to the invention is accommodated, which is used as an integrated color changer (ICC) and whose cf. Figures 2 to 5 Explained later.

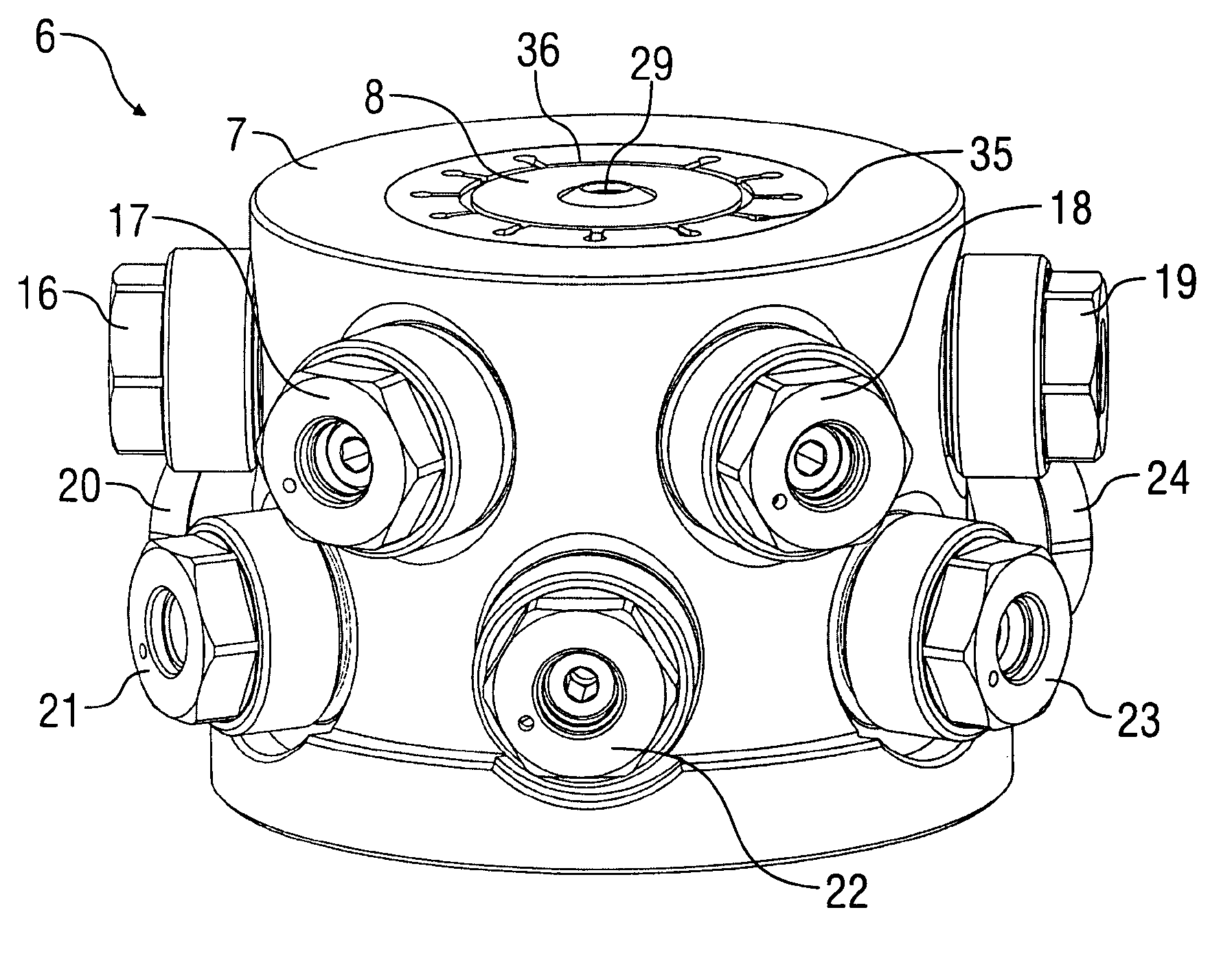

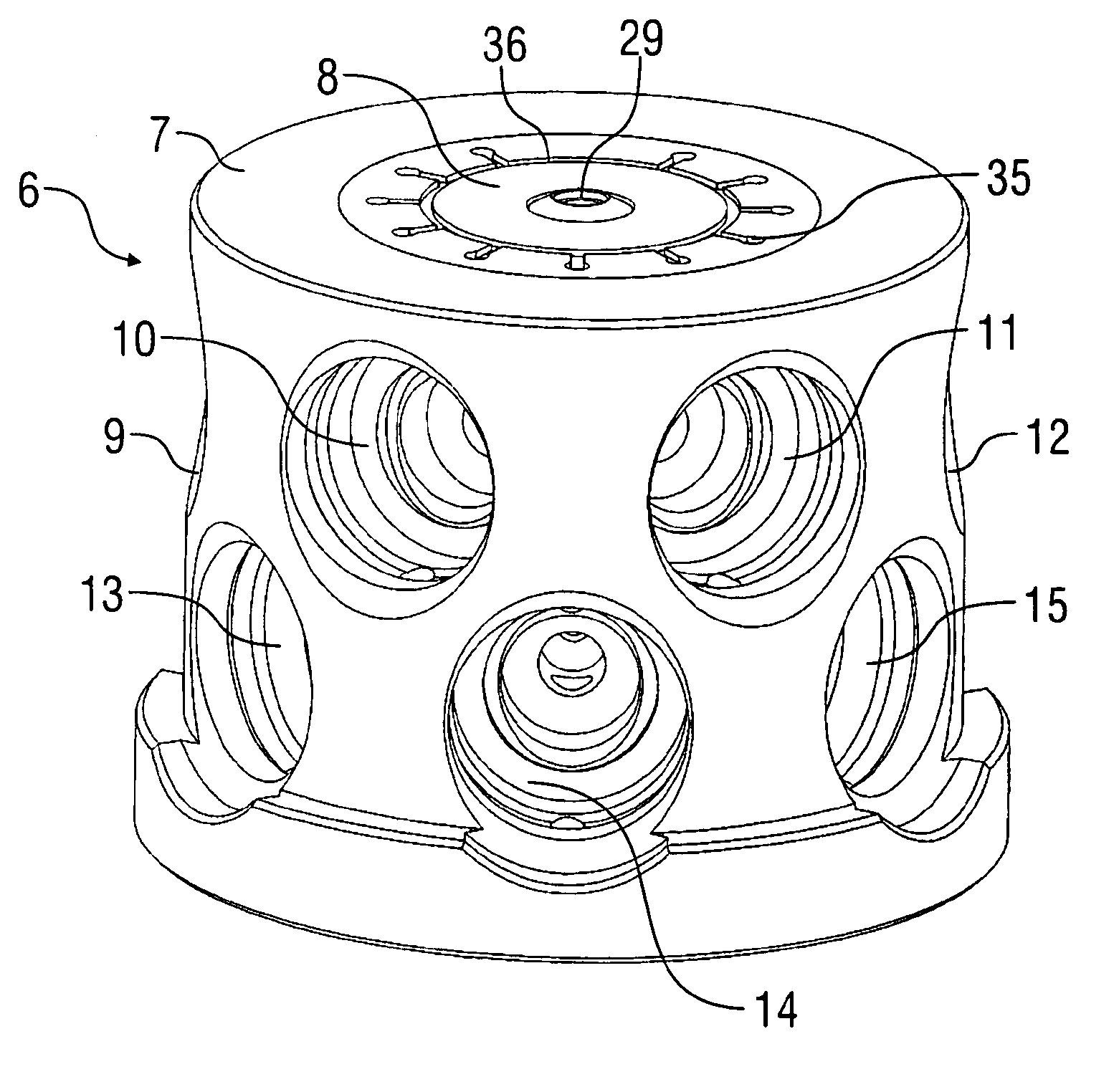

[0043] The valve unit 6 has a substantially cylindrical housing comprising a cylindrical casing 7 made of plastic (eg POM: polyoxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com