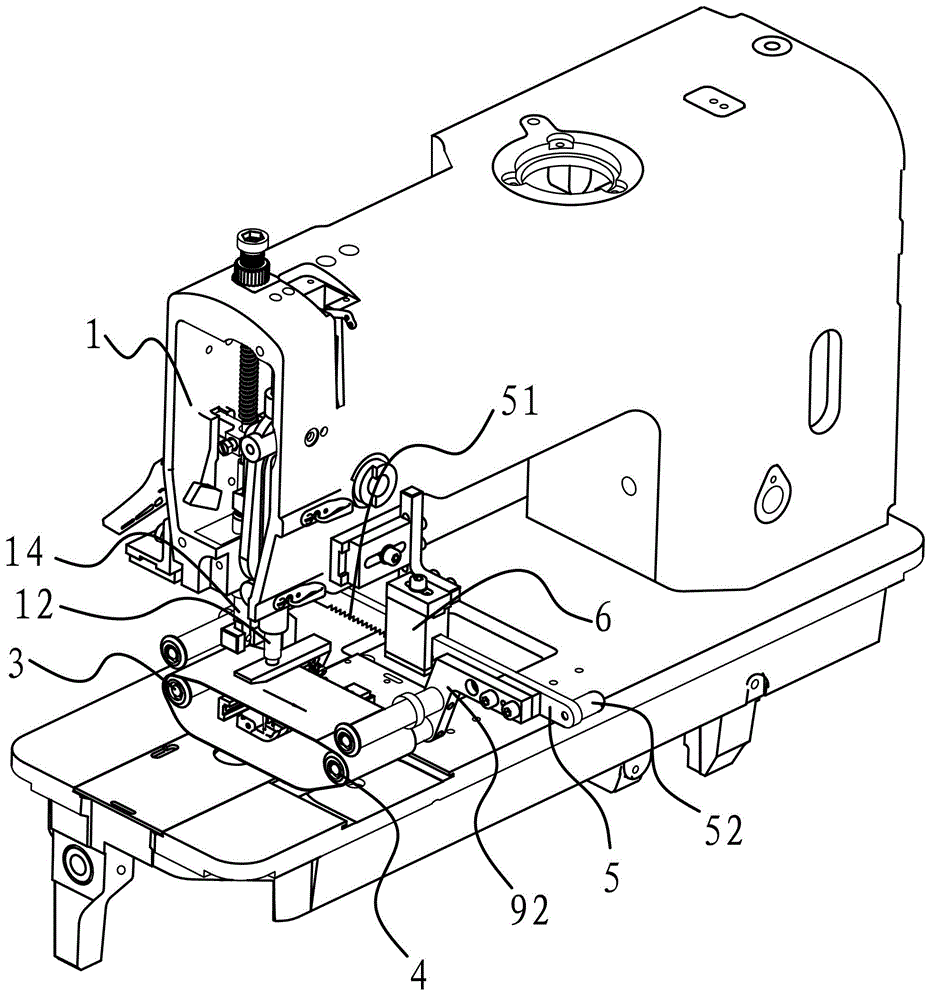

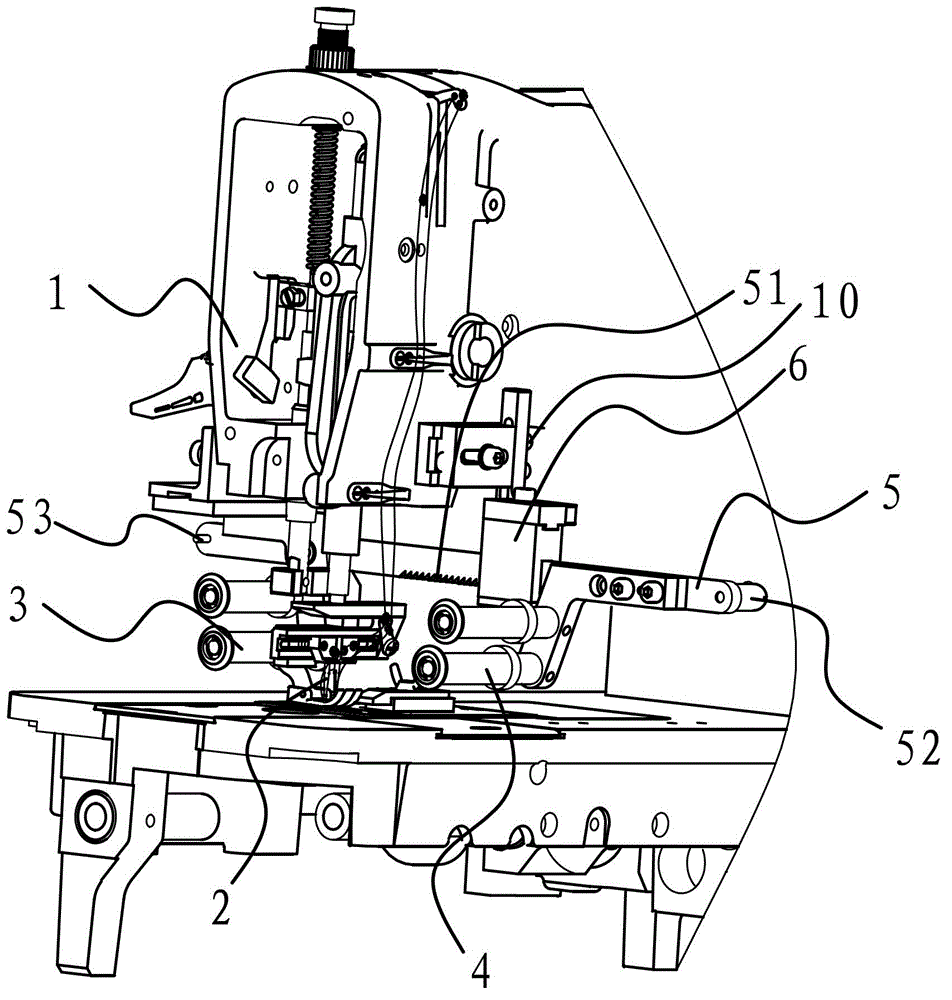

Cloth dragging device of sewing machine

A sewing machine and mopping technology, which is applied to sewing machine components, needle holders for sewing machines, sewing equipment, etc., can solve the problems of inconvenient operation, complex overall structure and high manufacturing cost, and achieve beautiful stitches, improve processing efficiency, and facilitate manipulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

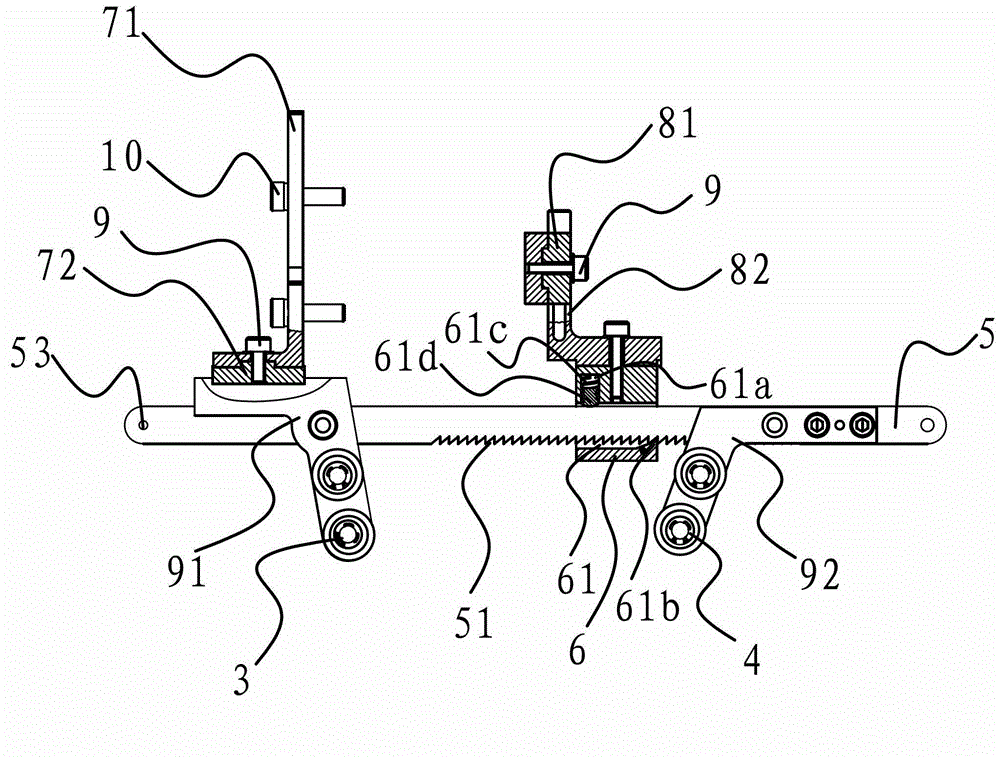

[0032] Such as Figure 5 and Figure 6 As shown, a needle bar 12 is provided on the machine head 1, and a needle bar joint 13 is fixed at the lower end of the needle bar 12, and the needle bar joint 13 has a U-shaped joint side slot 13a. The machine needle 2 is connected with the needle bar joint 13 through the needle distance adjusting structure. Wherein, the needle pitch adjustment structure includes a needle holder installation hole 13b opened on the needle bar joint 13, the needle holder installation hole 13b is strip-shaped and extends horizontally, and a needle holder 16 capable of sliding is provided in the needle holder installation hole 13b, the above-mentioned The machine needle 2 is fixed on the needle base 16, and a needle base locking screw 17 is arranged between the needle base 16 and the needle base installation hole 16a. When it is necessary to change the distance between two machine needles 2, you only need to loosen the needle seat locking screw 17, and sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com