U+U type laneway ventilating system of coalface

A technology for mining face and roadway ventilation, which is applied in mine/tunnel ventilation, mining equipment, earth-moving drilling and other directions, can solve problems such as difficult gas control, and achieve the effect of improving driving efficiency and reducing roadway engineering volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

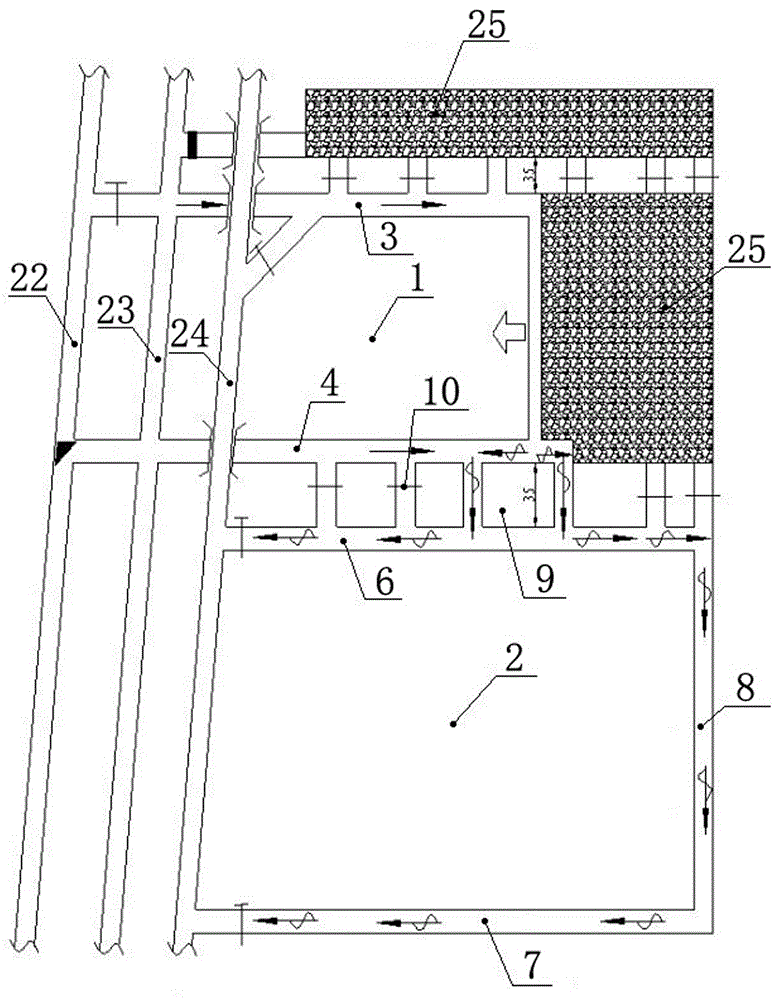

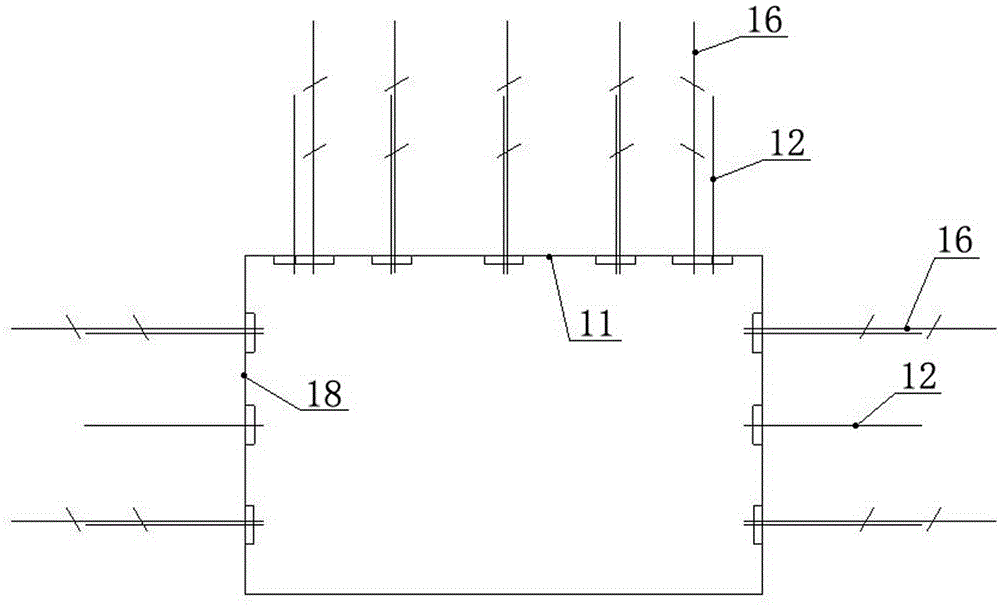

[0024] like figure 1 , 2 As shown, a U+U-shaped roadway ventilation system for a mining face includes a first mining face 1 and a second mining face 2 adjacently arranged; The roadway, the first U-shaped roadway includes the main air inlet lane 3 on both sides of the first mining face 1, the auxiliary air inlet and belt transport lane 4, and the first cutout 5 on the front side of the first mining face 1; The periphery of the second recovery working face 2 is provided with a second U-shaped roadway, and the second U-shaped roadway includes the first air return lane 6 and the second air return lane 7 on both sides of the second recovery working face 2, and the second recovery working face 2 The second cutout 8 on the front side; the auxiliary air inlet and belt transport lane 4 of the first U-shaped roadway is adjacent to the first air return lane 6 of the second U-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com