Antiknock container sealing structure

A container sealing and sealing ring technology, applied in the direction of locking equipment, etc., can solve problems such as inconvenience and laborious operation, and achieve the effect of preventing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

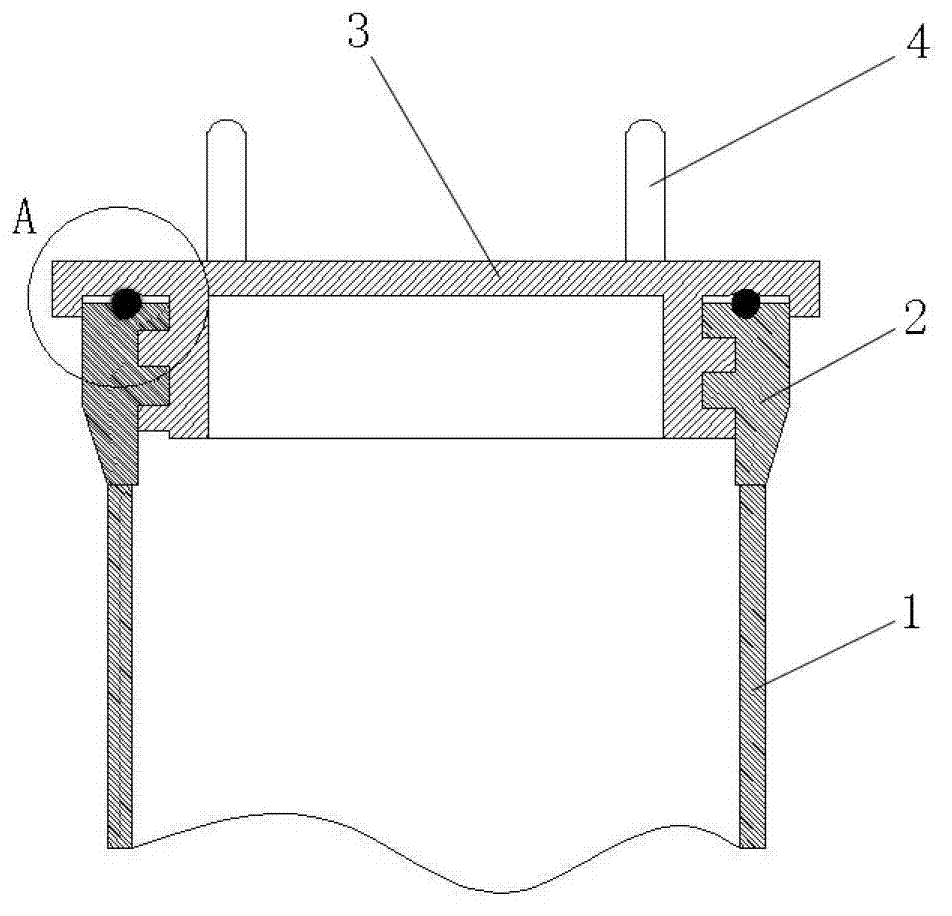

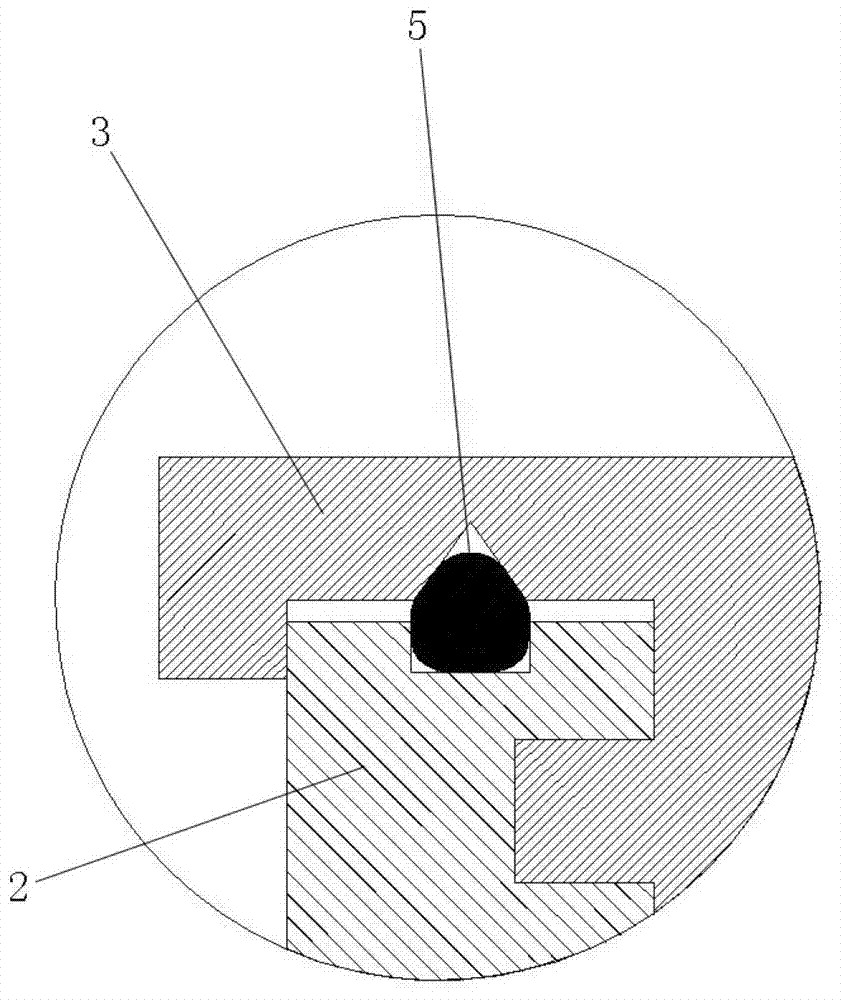

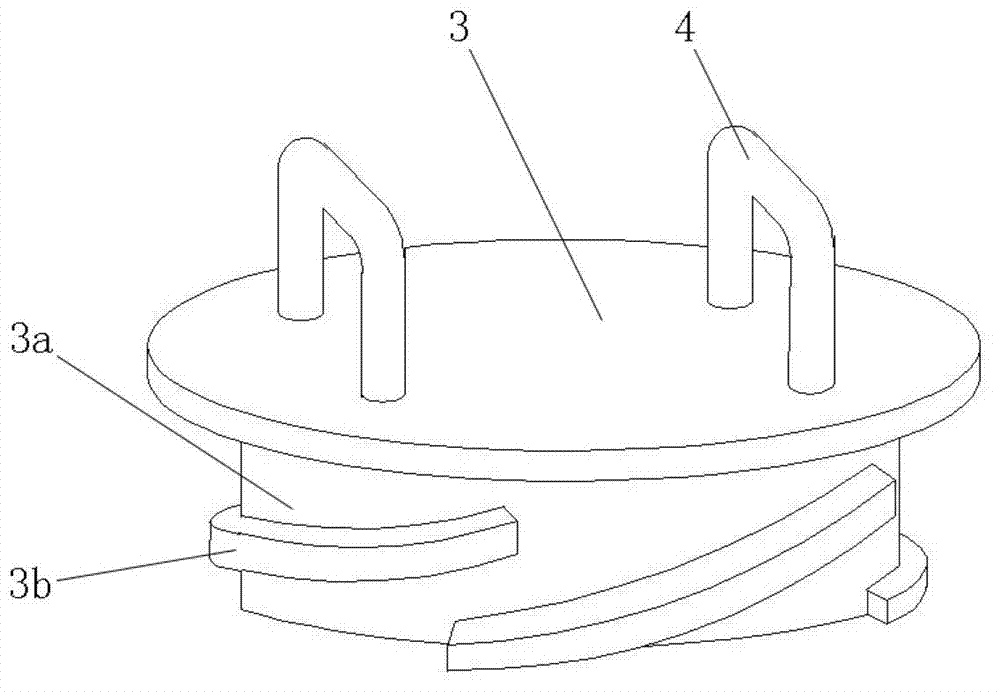

[0019] Reference attached figure 1 Attached Figure 5 , An anti-explosive container sealing structure, the structure of the anti-explosive container sealing structure includes an anti-explosive container body 1, a collar 2 and a cover 3, wherein the collar 2 is in the shape of a circular ring, and the collar 2 is fixed on the anti-explosive container At the opening of the container body 1, the top plane of the collar 2 is provided with an annular groove 2a, and the inner side of the collar 2 is provided with a multi-threaded thread 2b; the upper part of the lid 3 is in the shape of a disc, and the lower part of the lid 3 is cylindrical or Cylindrical shape, with a handle 4 on the top surface of the upper part of the cover 3, a retaining ring 3c on the side surface of the upper part of the cover 3, and a multi-threaded thread on the inner surface of the collar 2 on the outer surface of the lower part 3a of the cover 2b matching multi-threaded two 3b; on the bottom surface of the...

Embodiment 2

[0021] Reference attached figure 1 Attached Figure 5 , An anti-explosive container sealing structure, the structure of the anti-explosive container sealing structure includes an anti-explosive container body 1, a collar 2 and a cover 3, wherein the collar 2 is in the shape of a circular ring, and the collar 2 is fixed on the anti-explosive container At the opening of the container body 1, the top plane of the collar 2 is provided with an annular groove 2a, the inner side of the collar 2 is provided with a multi-threaded thread 2b, and a spring is provided on the thread 2b on the inner side of the collar 2 sheet. The rest of the structure is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com