SUV (sports utility vehicle) front cover paint spraying aid and using method thereof

A technology of front cover and auxiliary equipment, which is applied in the direction of spraying devices, coatings, and devices for coating liquid on the surface. Appearance quality, convenient and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

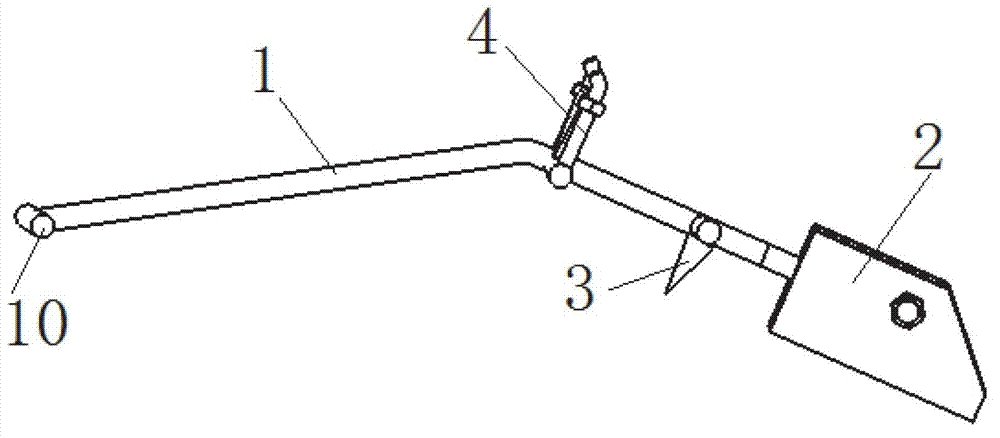

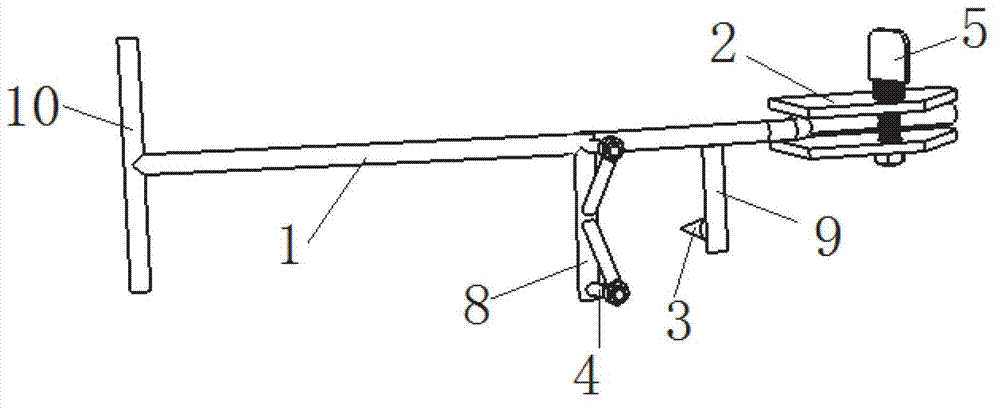

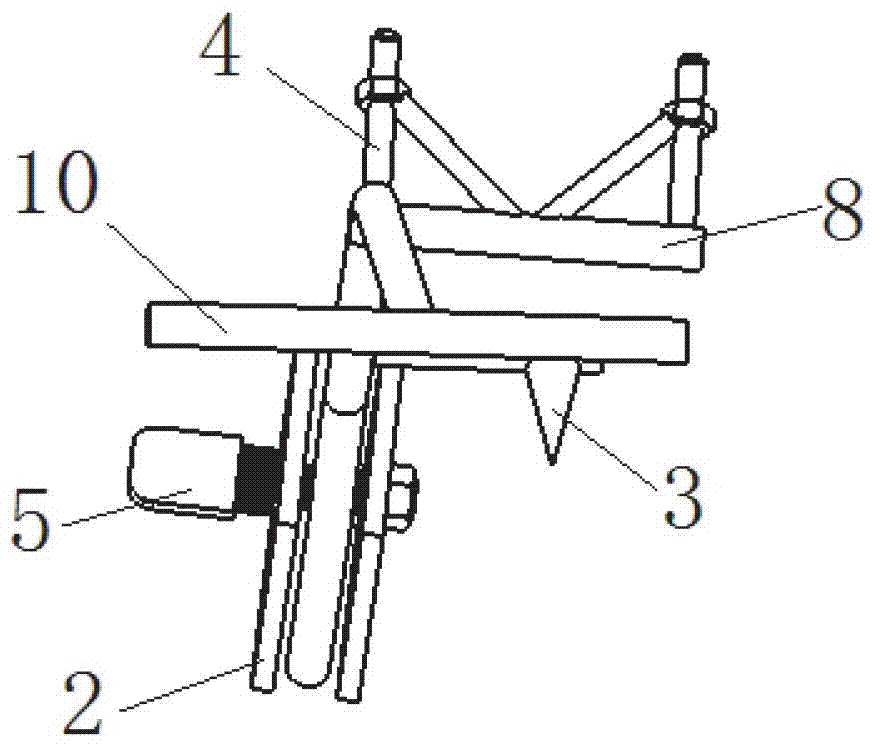

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown is an SUV car front cover painting aid of the present invention, which is used to clamp the front cover 6 of the vehicle body during the coating process of the intermediate coating. The painting aid includes a main pole 1 for supporting the front cover 6 The positioning assembly, the splint assembly and the small strut 3 that are hingedly connected to the lock on the front cover 6 of the vehicle body, the main strut 1 is a rod that is bent downward in a vertical plane, along the length of the main strut 1 Direction, the positioning assembly, the small strut 3 and the splint assembly are fixedly connected to the main strut 1 in sequence, and the small strut 3 protrudes toward the bottom of the main strut 1 for supporting on the front cross member 7 of the vehicle body. Compared with the prior art, the painting aid has a simple structure, is easy to operate, and can fully meet the requirements of the productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com