Explosive fastening screws

A technology for fastening screws and screws, which is applied in the direction of connecting components, pins, mechanical equipment, etc., can solve problems such as difficult installation, inability to expand and open, and potential safety hazards, and achieve the effect of improving installation efficiency and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment one, as image 3 As shown, the main body screw 2 includes two independent parts, the screw body 23 and the limit expansion head 25, the tapered surface 21 is arranged on the upper part of the limit expansion head 25, and the limit expansion head 25 is sleeved on the screw rod The body 23 can be moved up and down to a suitable position to adapt to installation holes of different depths. After moving to a suitable position, the limit expansion head 25 can be fixed on the screw body 23 by pressing, punching a concave point 20 or hitting a pin. That is, the screw body 23 can be rotated, so that the non-slip expansion screw sleeve 1 expands and opens under the pressure of the conical surface 21 of the limiting expansion head 25 . The lower part of the screw body 23 can be either a threaded rod with an external thread or a rod with a smooth side wall. When it has an external thread, it can also be used to screw the support as described in the first embodiment The ...

Embodiment 2

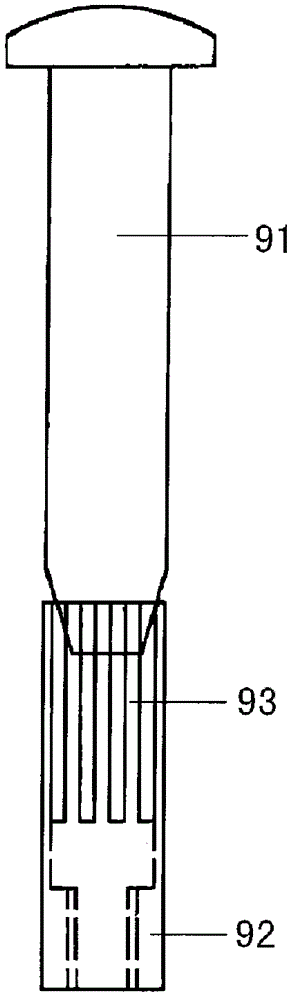

[0032] Embodiment two, such as Image 6 As shown, the main body screw 2 is a chandelier screw, its tail is provided with an external thread to cooperate with the non-slip expansion screw sleeve 1, its middle is provided with a tapered surface 21, and its top is provided with an enlarged nut 26, the nut 26 The periphery is provided with concavo-convex patterns, and the top surface is provided with a straight, cross or polygonal groove 27, which can be used for twisting the main body screw 2. When installing, drive the anti-slip expansion screw sleeve 1 into the installation hole, turn the main body screw 2, due to the anti-slip effect of the anti-skid positioning of the outer wall protrusion 12 of the anti-slip expansion screw sleeve 1, the anti-slip expansion screw sleeve 1 is under the pressure of the tapered surface 21 The expansion is opened, and the main body screw 2 can be installed with lighting or other objects.

Embodiment 3

[0033] Embodiment three, as Figure 7 As shown, the main body screw 2 is a welding connection screw, and its tail is provided with an external thread to cooperate with the non-slip expansion screw sleeve 1. The middle part is provided with a tapered surface 21, and its top is a flat connection head 28. The side wall of the tip 28 has at least one plane for welding other objects, in the present embodiment, such as Figure 8 As shown, the cross-section of the splice 28 is generally square. After turning the main body screw 2 to make the anti-slip expansion screw sleeve 1 open and fixed in the installation hole, other objects can be welded and fixed on the connecting head 28 by welding. In addition, a limiting convex edge 29 that limits the depth of the main body screw 2 into the installation hole can be provided along the periphery at the joint between the connecting head 28 and the middle part of the main body screw 2, and the exposed connecting head after installation can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com