Wind power high temperature electrolytic hydrogen preparation system and method

A high-temperature electrolysis and hydrogen production system technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of difficult to guarantee stability, slow development of electrolytic hydrogen production, and large fluctuation of wind power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

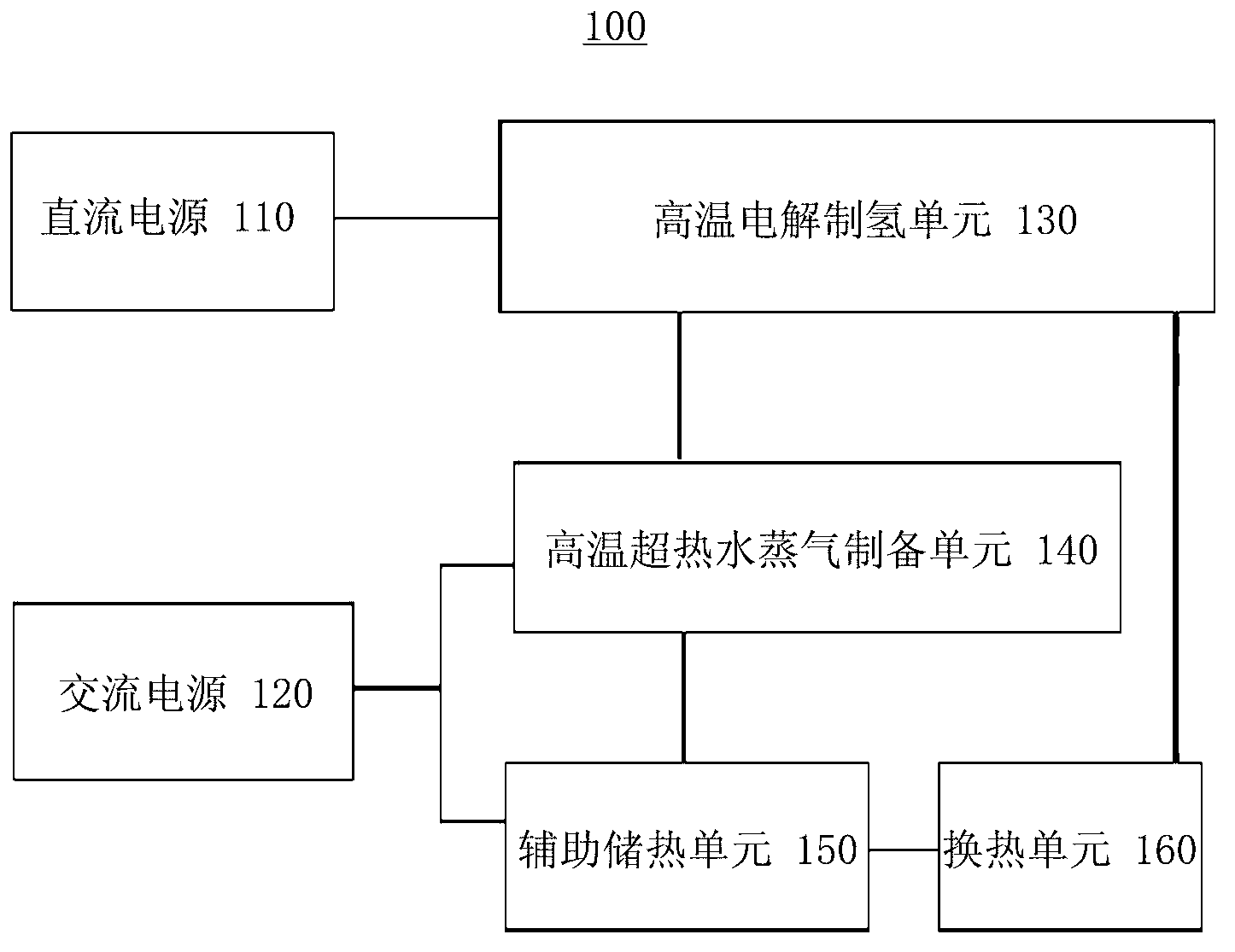

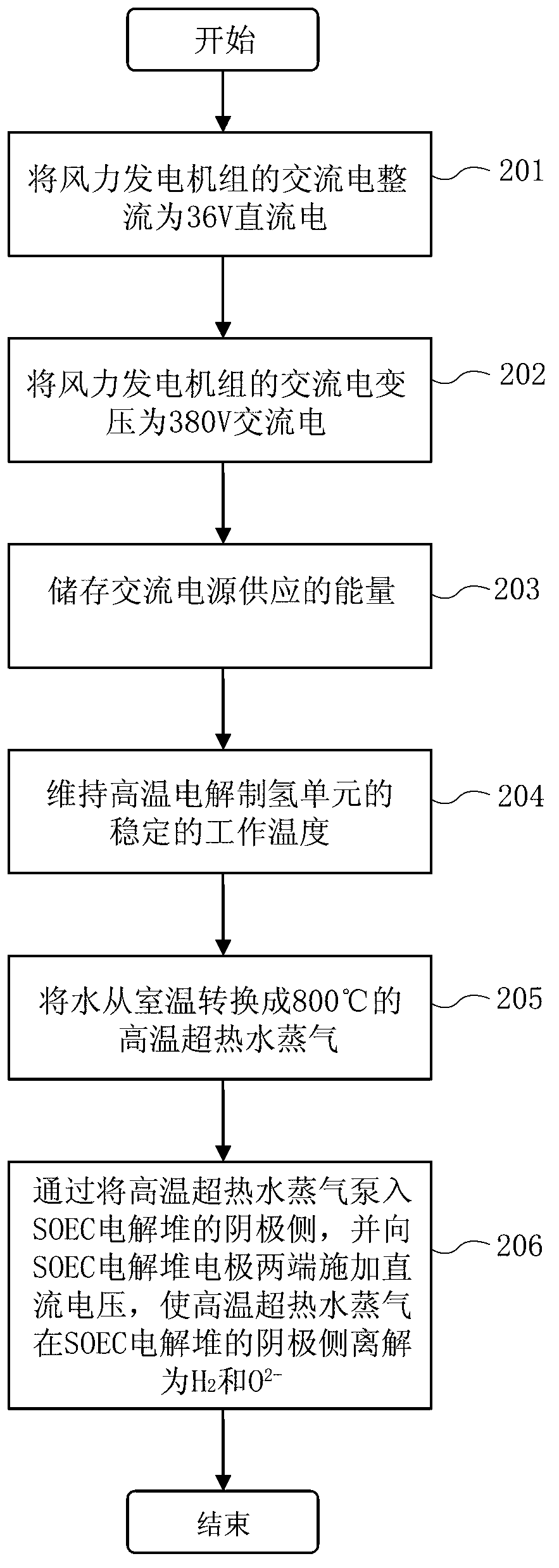

[0018] Embodiments of the invention will now be described in detail, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like parts throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

[0019] The present invention adopts high temperature electrolysis hydrogen production technology (High Temperature Electrolysis, HTE for short), and performs electrolysis hydrogen production at a high temperature of about 700°C to 900°C. In this way, part of the energy for hydrogen production from high-temperature superheated steam can be provided by cheap thermal energy. At the same time, because the high-temperature electrolytic hydrogen production technology works at high temperature, the reaction power is accelerated, the energy loss caused by electrode polarization is reduced, the overall efficiency of the system is improved, and the power consumption of electrolytic hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com