Automatic feeder for electrode plates

A technology of automatic feeding and electrode sheets, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of rapid processing of unfavorable products, slow manual work efficiency, crushing workers' fingers, etc., to save working time, work conveniently, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The electrode sheet automatic feeder provided by the present invention will be further described in detail below through specific examples.

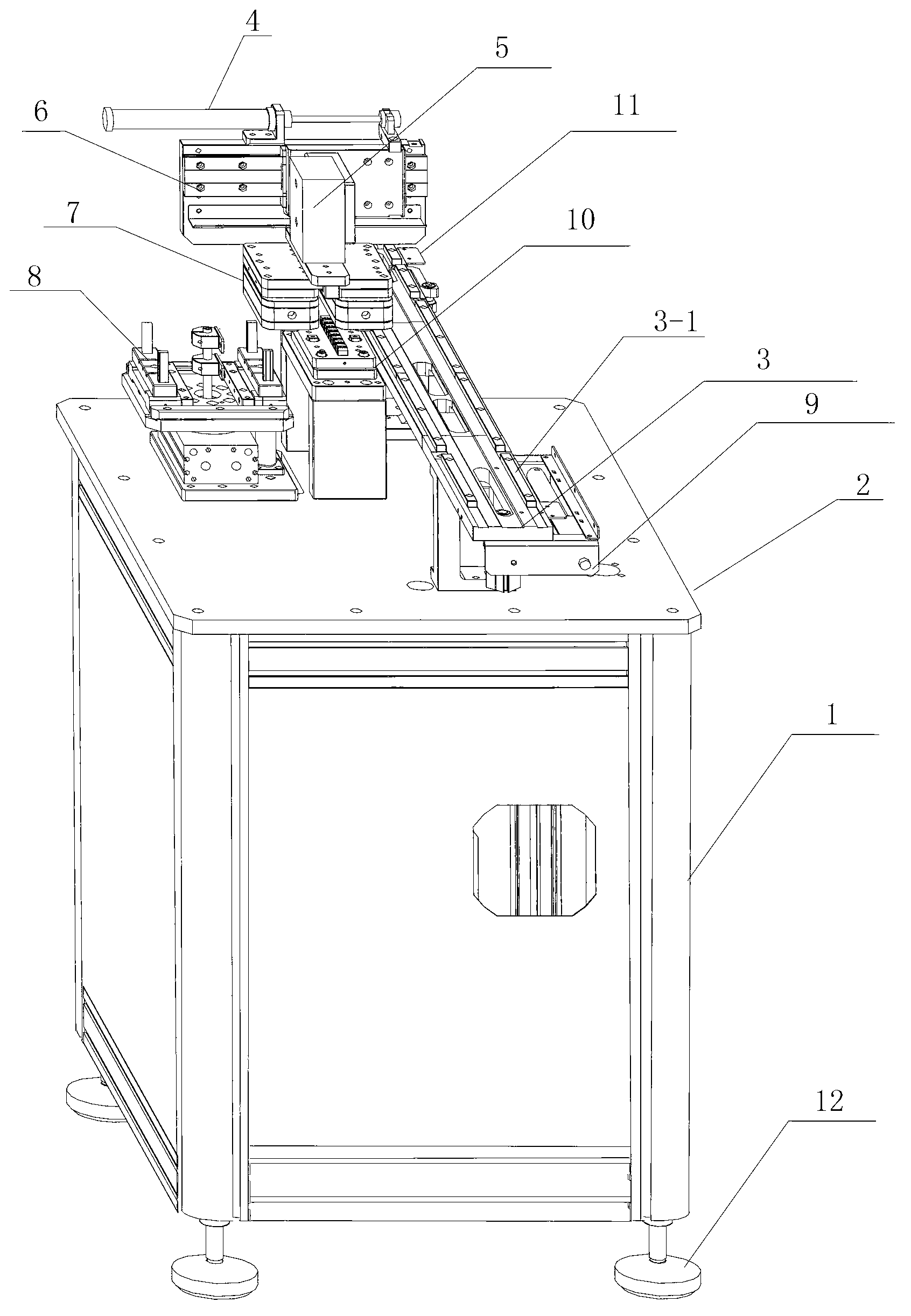

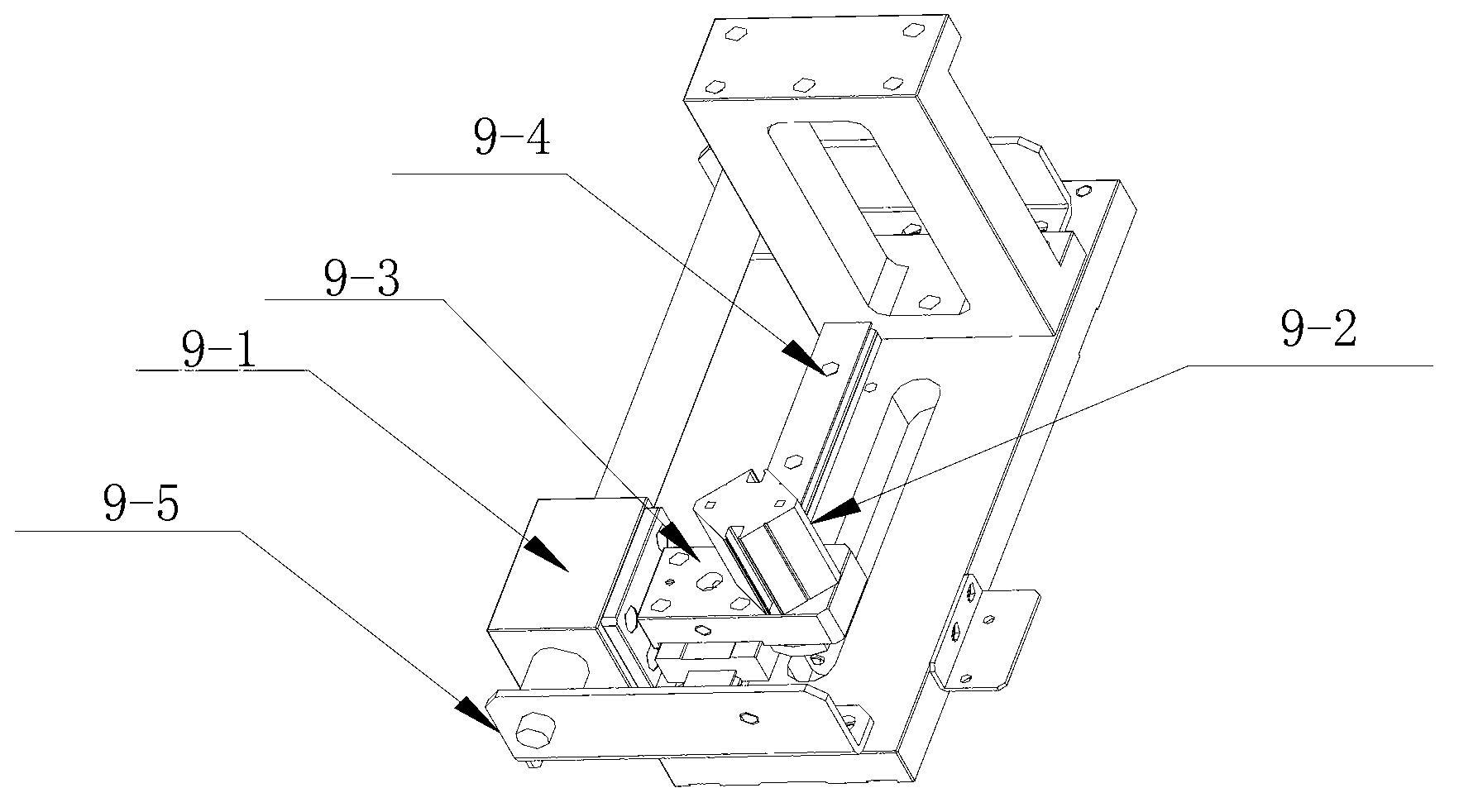

[0015] like figure 1 As shown, the electrode sheet automatic feeder includes an electric control cabinet 1, a mechanical base plate 2, a fixture guide rail 3, a left and right transplanting cylinder 4, a jacking cylinder 5, a linear slide rail 6, an electrode sheet adsorption block 7, and an electrode sheet feeding Module 8, automatic displacement fixture module 9, wherein the mechanical base plate 2 is installed above the electric control cabinet 1, the fixture guide rail 3 is fixed on the mechanical base plate 2 through the support, and the linear slide rail 6 is fixed on the mechanical base plate through the vertical plate. On the bottom plate 2 , the electrode piece adsorption block 7 is connected with the left and right transplanting cylinders 4 and the jacking cylinder 5 , and is installed on the linear slide rail 6 . The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com