Cycling system of a plurality of ore pulp agitating grooves and cycling method thereof

A slurry mixing tank and circulation system technology, which is applied to the circulation conveying system and its circulation field, can solve the problems of unsafe time-consuming, polluting the environment, affecting the continuity of slurry transportation, etc., so as to improve work efficiency and avoid environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

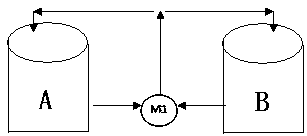

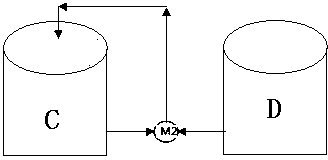

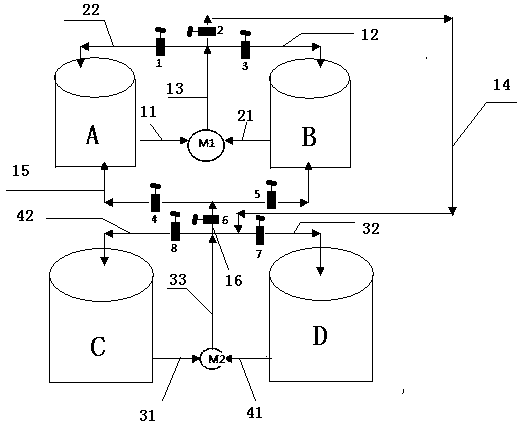

[0028] Combine below image 3 , the present invention is further described:

[0029]A circulation system of multiple ore slurry stirring tanks, at least including stirring tank A, stirring tank B, stirring tank C and stirring tank D, each stirring tank D is connected to the main pump, characterized in that: any two stirring tanks The ore pulp between them is poured mutually, while the rest of the mixing tanks continue to deliver the ore slurry to the main pump. A first output pipeline 11, AB general pipeline 13 and A second output pipeline 12 are sequentially connected between the output end of the stirring tank A and the input end of the stirring tank B, and B is connected between the output end of the stirring tank B and the input end of the stirring tank A in sequence. First output pipeline 21, AB general pipeline 13 and B second output pipeline 22, stirring tank A and stirring tank B share AB general pipeline 13, on B second output pipeline 22, be provided with the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com