Improved pin socket for surface mount

A plug-in connector, mesh technology, applied in the field of pin sockets, can solve the problems of inaccurate function, bulky, disconnection of plug-in connectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

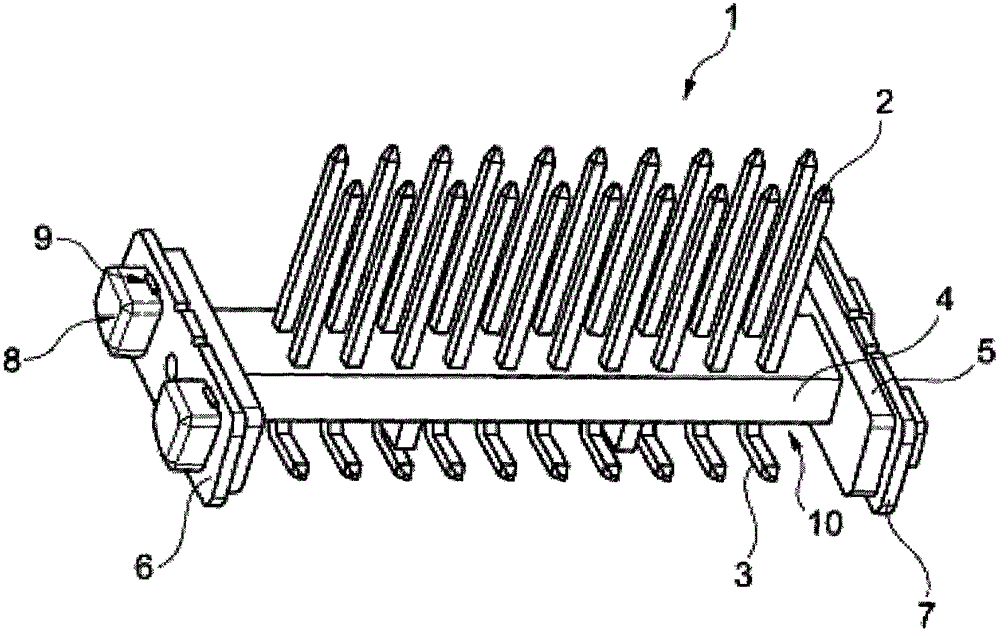

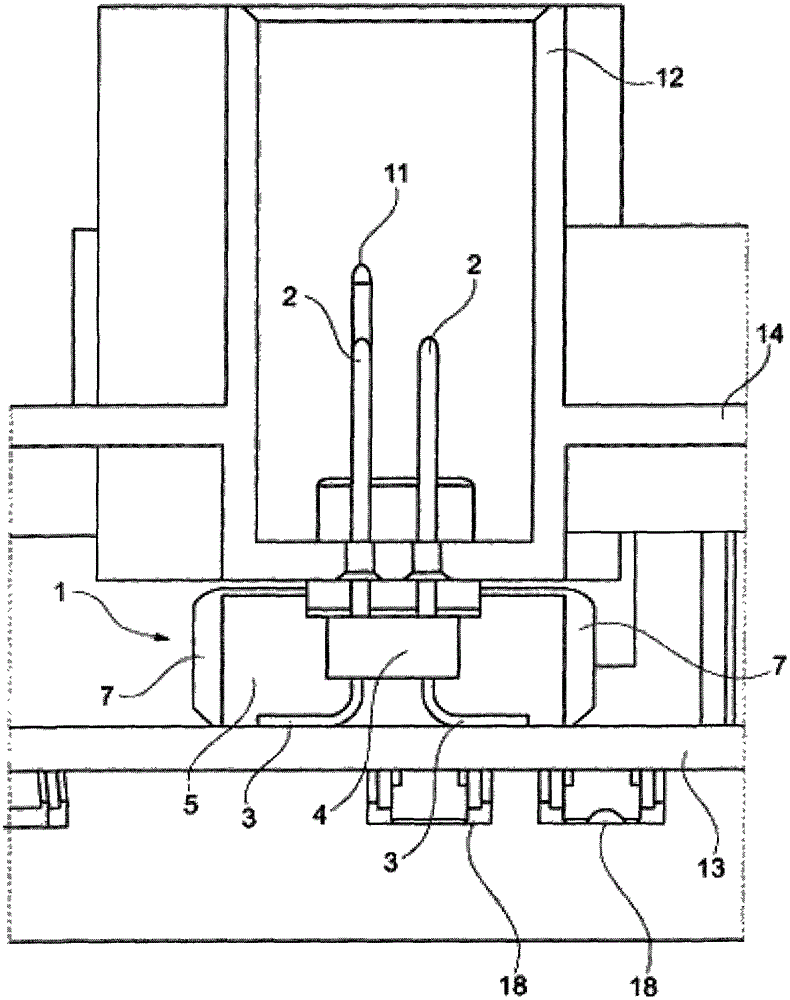

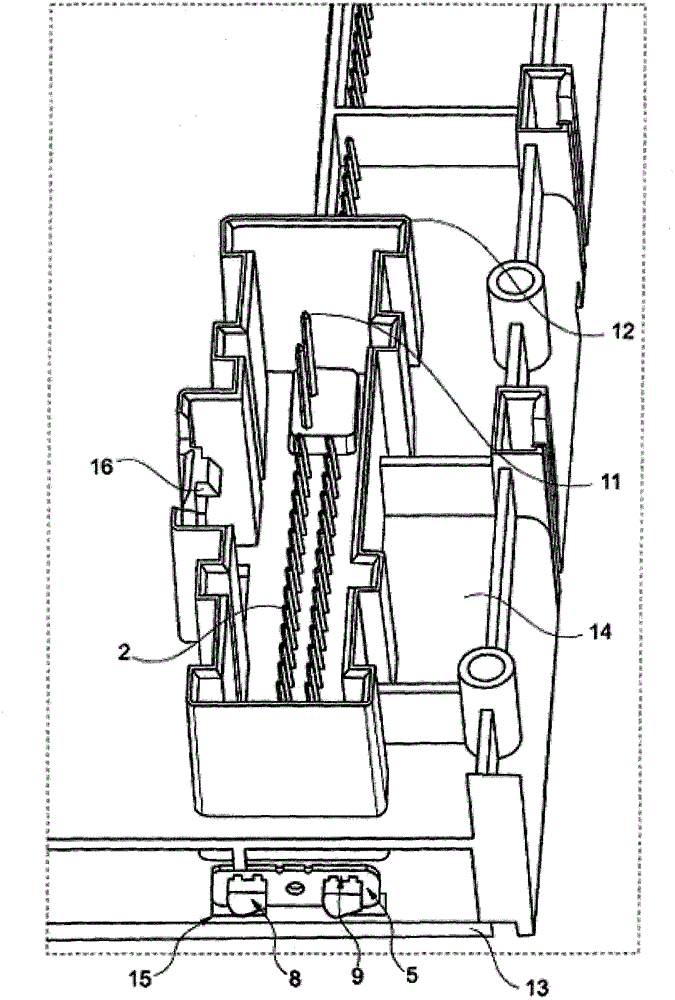

[0022] figure 1 is a specific embodiment of the present invention, wherein a pin socket is shown as the plug-in connector 1 of the present invention. The plug-in connector 1 comprises a one-piece insulating body 4 made of plastic. The insulating body 4 comprises a web-shaped central region and plates 5 on its end faces, which each extend perpendicularly to the longitudinal direction of the insulating body. A pin-shaped solderable contact 2 with a rectangular cross-section (for example made of copper) is inserted into the web-shaped intermediate region of the insulating body 4 by overmolding technology. These contacts 2 are used to establish an electrical connection with a complementary second plug-in connector (in this embodiment a card socket, which is not shown in the figure). The contacts 2 are arranged in a regular grid comprising two rows. The contact 2 includes a bent portion 3 parallel to the surface of the circuit board ( figure 1 (not shown in ), the curved portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com