Wiring sleeve

A technology of wiring sleeves and wiring hoops, applied in the direction of connecting end caps, etc., can solve the problems of low safety, insufficient environmental protection and poor durability of black tape

Inactive Publication Date: 2012-12-26

内蒙古建设集团股份有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to overcome the disadvantages of low safety, poor durability, and insufficient environmental protection of black tape, the invention provides an insulation protection device for wiring sleeves. When the workers repeatedly pull out or push the connected wire connectors due to maintenance or other reasons, the wire connectors will not be damaged or loosened.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

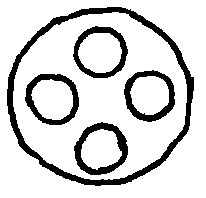

[0010] (1) In the junction box, first connect several wires that need to be jointed together from the wiring hoop ( image 3 ) through several holes;

[0011] (2) Connect the wire connector according to the standard;

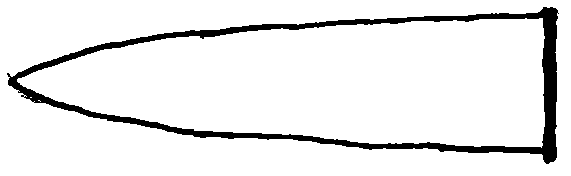

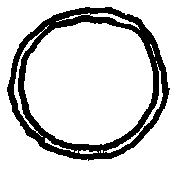

[0012] (3) Connect the connected wire connector to the wire hoop ( image 3 ) together with the terminal block ( figure 1 ) until the wiring socket ( figure 2 ) over the wire clamp ( image 3 )until.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a device for carrying out insulation protection on an electric wire joint in construction engineering. The device consists of a wiring sleeve and a wiring loop, wherein the round wiring loop is 15 mm in diameter and is made of a rubber material with the thickness of 5 mm, four small holes with the diameter of 4mm are uniformly distributed inside the wiring loop, and the wiring loop is used for fixing the electric wire joint and the wiring sleeve; and the wiring sleeve is made of rubber with the thickness of 1 mm, is 45mm long, is 12 mm in caliber, is shaped like a balloon and is used for carrying out the insulation protection on the electric wire joint. When the device is specifically implemented, some lead wires in need of jointing together in a junction box respectively pass through the small holes of the wiring loop, then the ends of the wires are jointed together, and finally, the wiring sleeve is sleeved on the ends of the wires until the sleeve opening of the wiring sleeve is sleeved with the wiring loop.

Description

Technical field: [0001] The invention relates to an insulation protection device for electric wire joints in construction engineering. Background technique: [0002] At present, the known insulating protection devices for wire joints in construction projects are generally black tapes, but the black tapes have poor durability, are prone to aging and fall off, and cannot be reused. Invention content: [0003] In order to overcome the disadvantages of low safety, poor durability, and insufficient environmental protection of black tape, the invention provides an insulation protection device for wiring sleeves. The wire connectors are not damaged or loosened when workers repeatedly take out or push forward the connected wire connectors due to maintenance or other reasons. It can even be reused. [0004] The technical solution adopted by the present invention to solve the problem is: first pass all the wires that need to be connected together in the junction box through the wi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01R4/22

Inventor 孟图力格尔

Owner 内蒙古建设集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com