Washing control system for double-clutch automatic gearbox

A technology of automatic transmission and flushing system, which is applied in vehicle cleaning, electrical program control, program control in sequence/logic controller, etc. It can solve the problem of affecting the normal operation of solenoid valves and affecting the safe driving of wet dual-clutch automatic transmissions , blockage of solenoid valves, etc., to avoid excessive pressure rise, easy data collection, and flexible cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

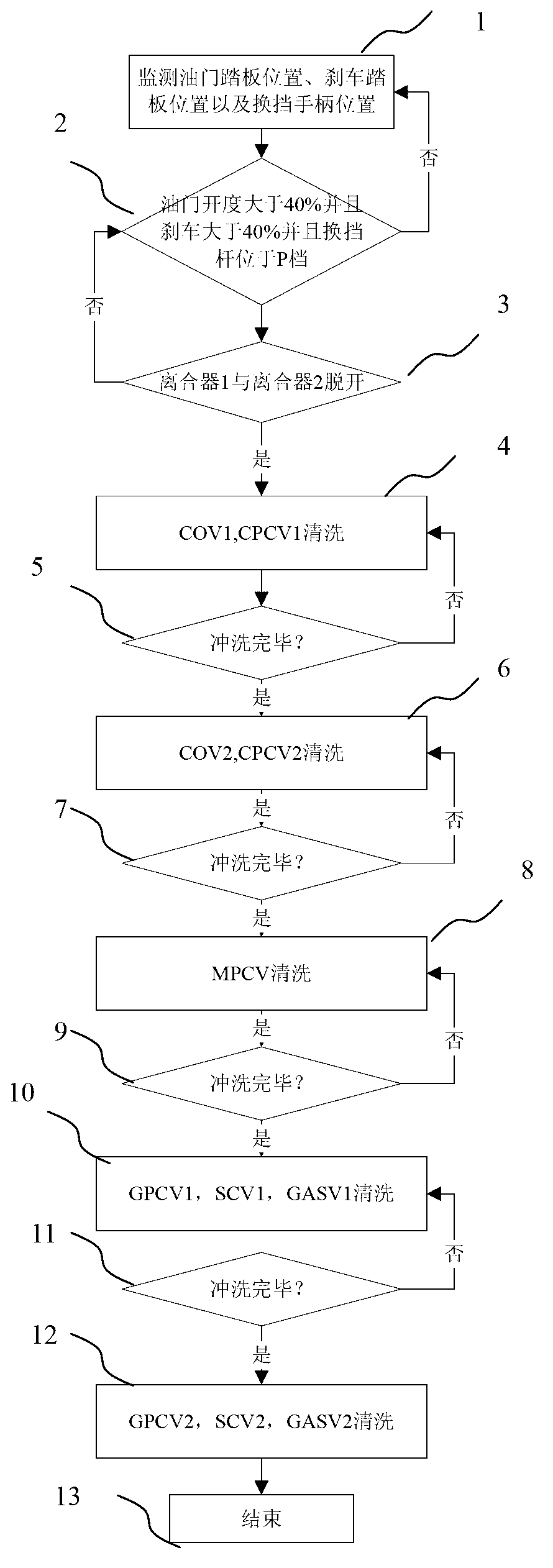

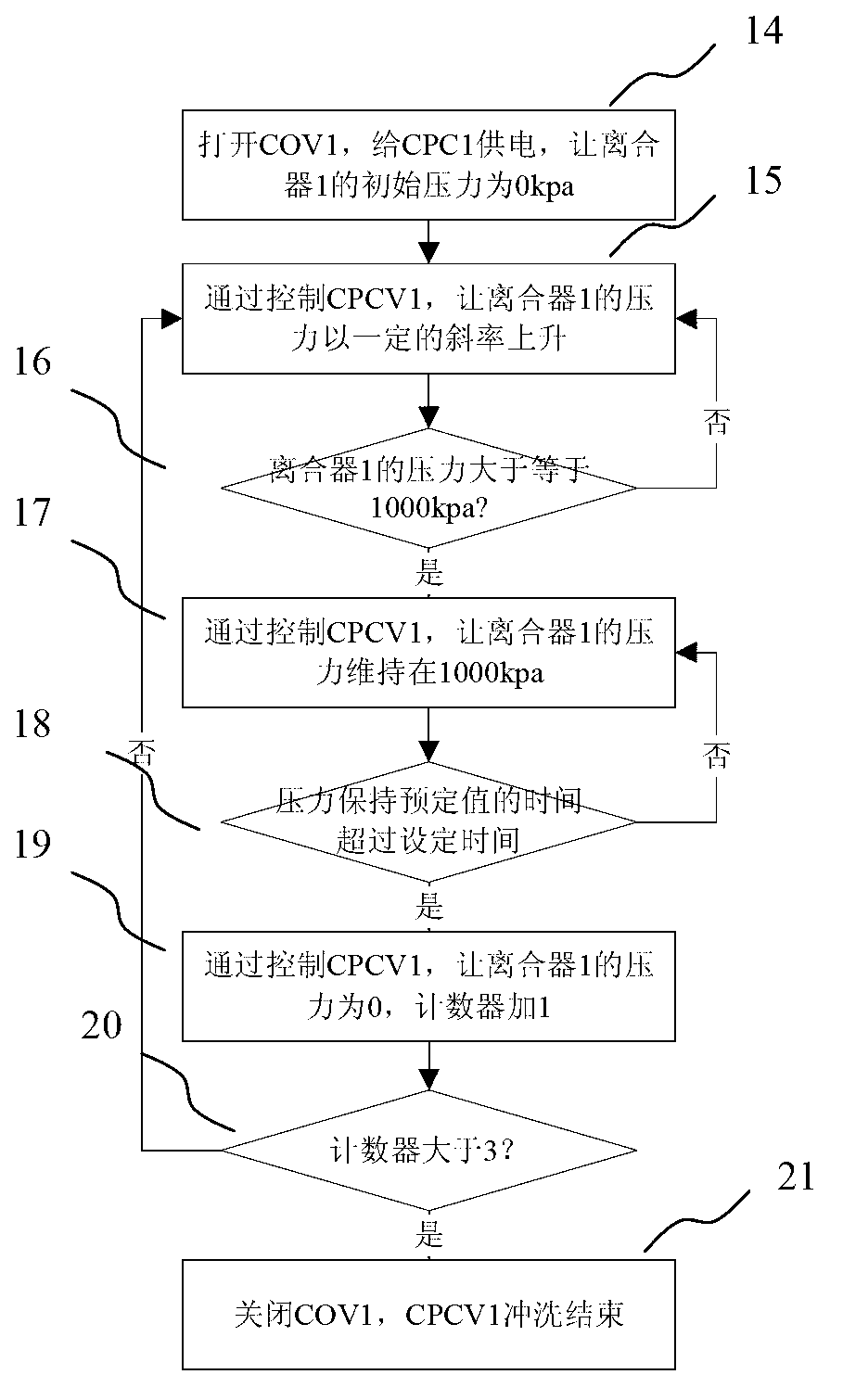

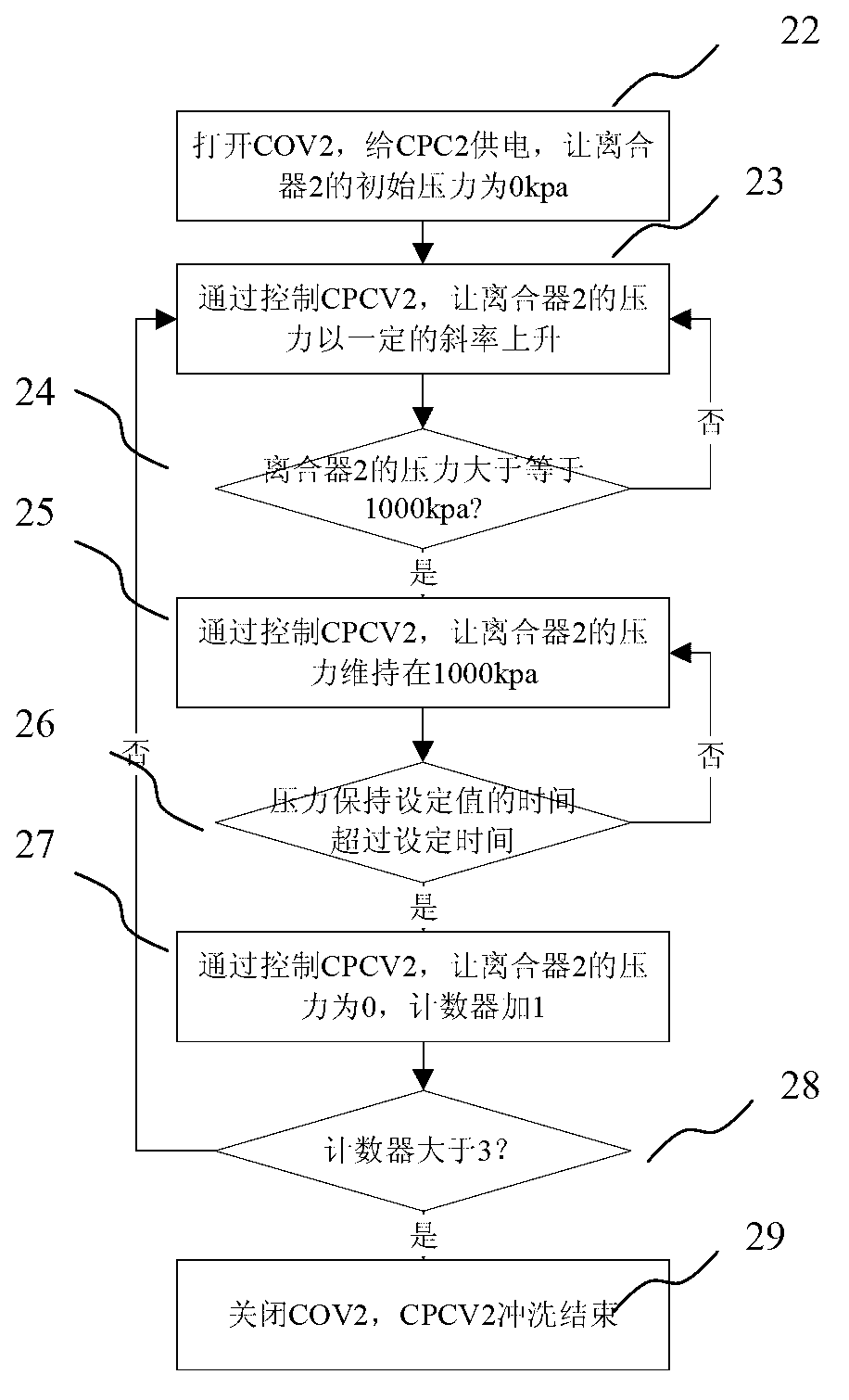

[0033] The flow chart of the flushing control of the electromagnetic valve of the wet dual-clutch automatic gearbox of the present invention is as attached figure 1 shown. Accelerator pedal position, brake pedal position and shift lever position are collected (1). Determine whether the collected accelerator pedal is depressed, whether the preferred opening is greater than 40%, whether the brake pedal is depressed, whether the preferred opening is greater than 40%, and whether the shift handle is in position P (2). If the accelerator pedal is greater than 40%, the brake pedal opening is greater than 40%, and the shift lever is in the P position (3), judge whether the pressure of clutch 1 and clutch 2 are both 0, if so, it means that clutch 1 and clutch 2 are disengaged (4). If clutch 1 and clutch 2 are disengaged, call COV1, CPCV1 cleaning function (5), if CPCV1 cleaning function ends, call COV2, CPCV2 cleaning function (6), if COV2, CPCV2 cleaning ends, call MPCV cleaning fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com