Deformable baffle of conveying belt

A conveyor belt and baffle technology applied in the field of conveyor belts to achieve the effects of low manufacturing cost, convenient application, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Several embodiments of the present invention are discussed in detail below with reference to the accompanying drawings.

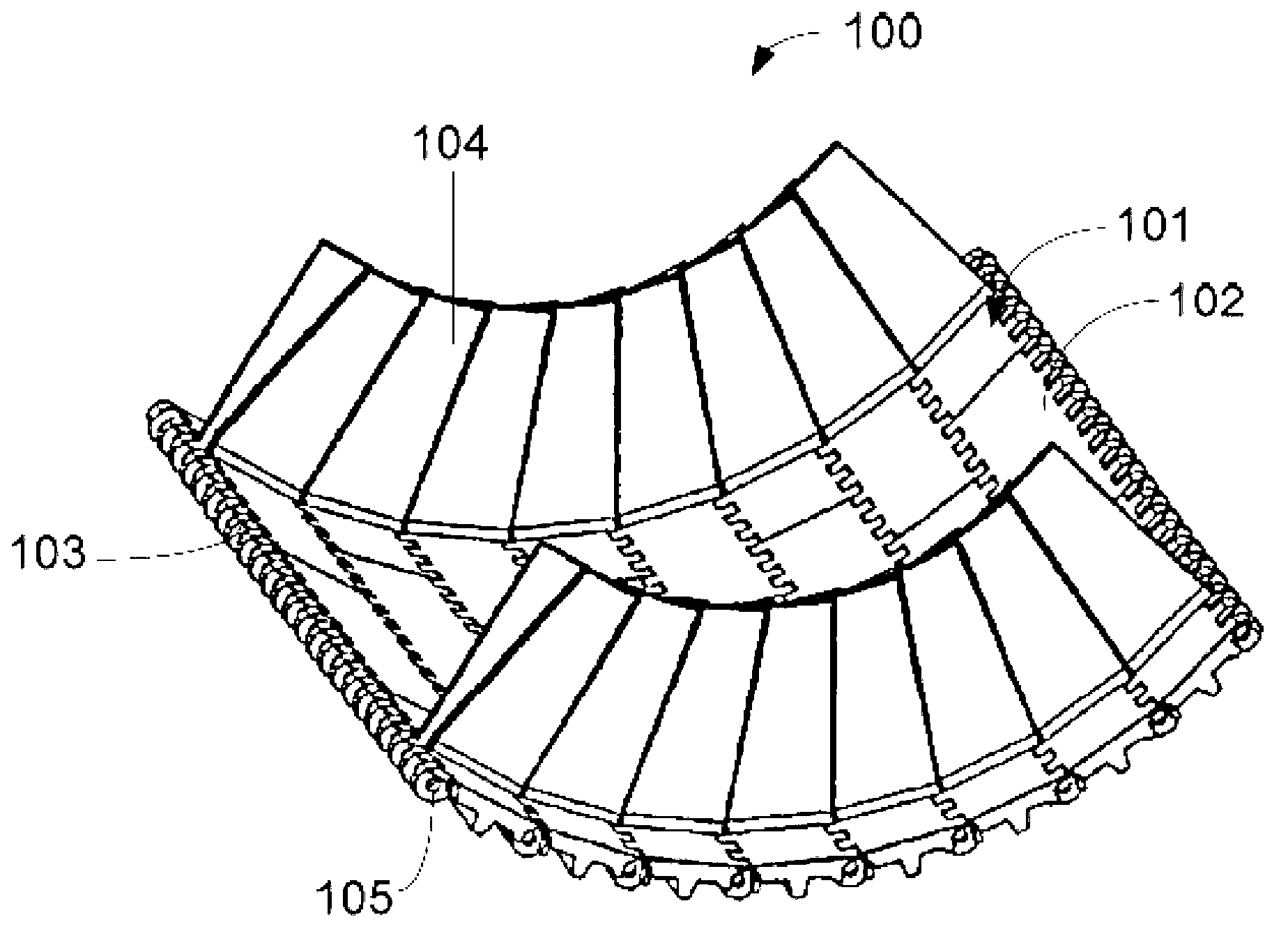

[0021] figure 1 The basic structure of the deformable baffle for the conveyor belt of the present invention is schematically shown. As shown in the figure, the deformable baffle 100 of the conveyor belt of the present invention mainly includes: a baffle 101 , a baffle 102 , a collar part 103 , a flap 104 and a connecting rod 105 .

[0022] exist figure 1 In the shown embodiment, there are a plurality of baffle plates 101 arranged side by side, and these baffle plates 101 further include: a baffle plate 102, and sleeves arranged in rows on the two long sides of the baffle plate 102 at predetermined intervals. The ring component 103 and the two flaps 104 are respectively pivotally connected to the two short sides of the blocking piece 102 .

[0023] In addition, the connecting rod 105 passes through a row of collar parts 103 on respective sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com