Shaping device and method for wrapped edge of box sealing adhesive tape

A technology of shaping device and tape, applied in packaging and other directions, can solve problems such as product spillage, product damage, affecting normal storage, etc., and achieve ideal results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

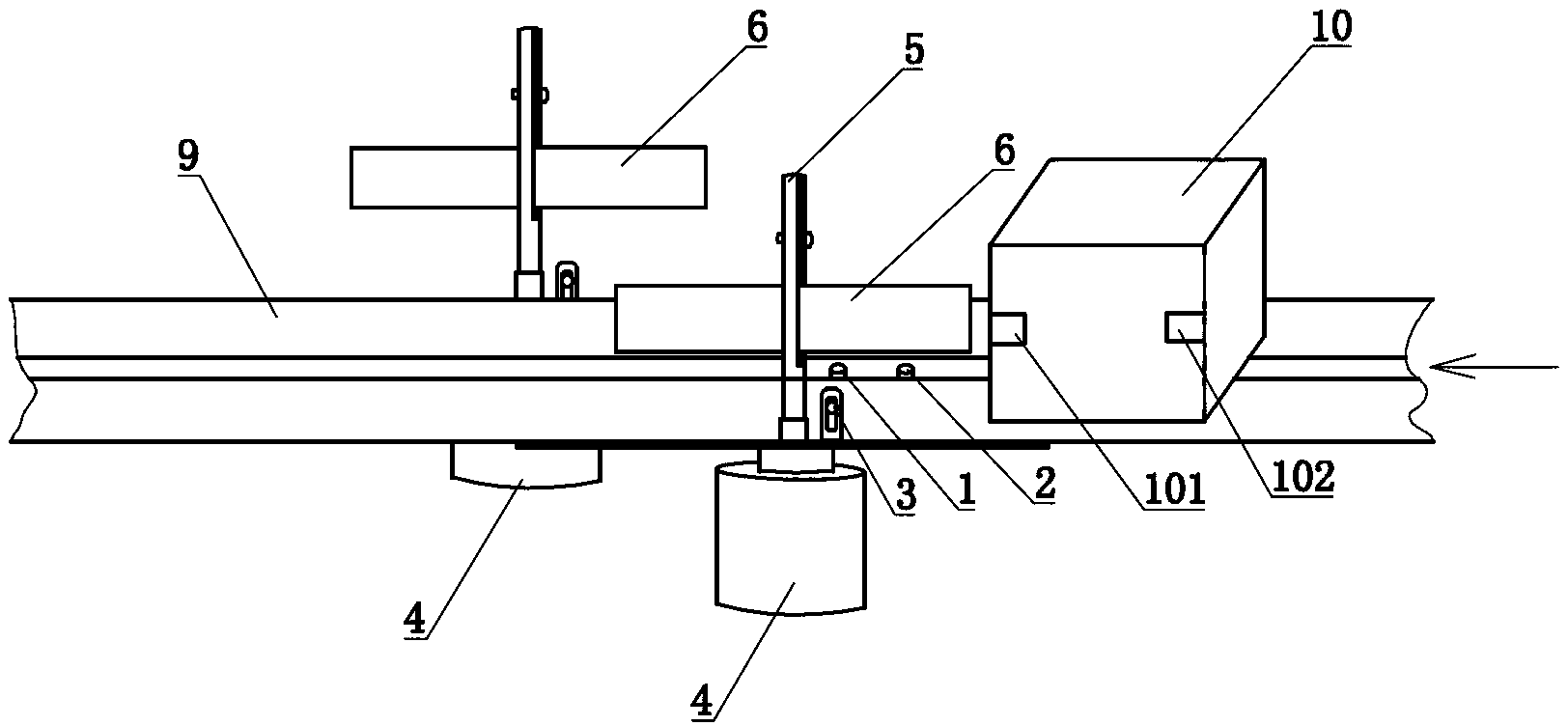

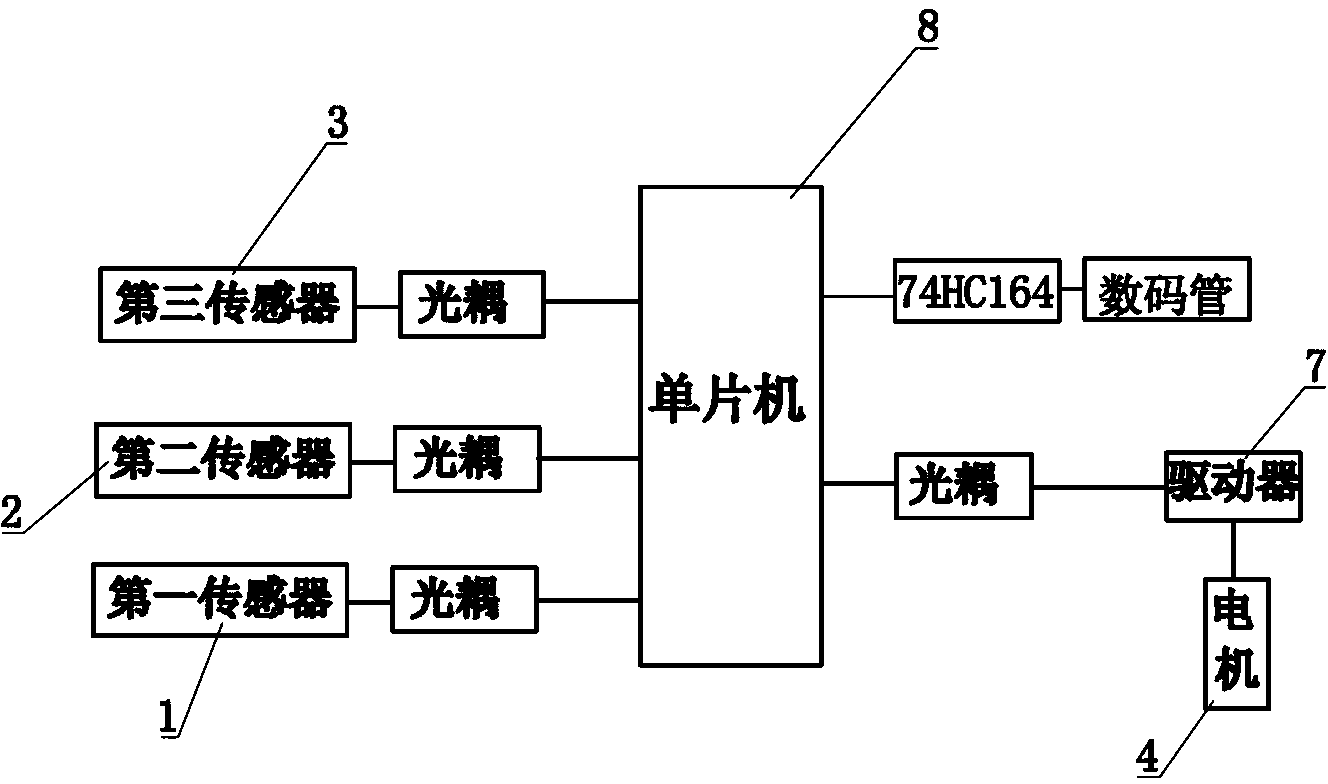

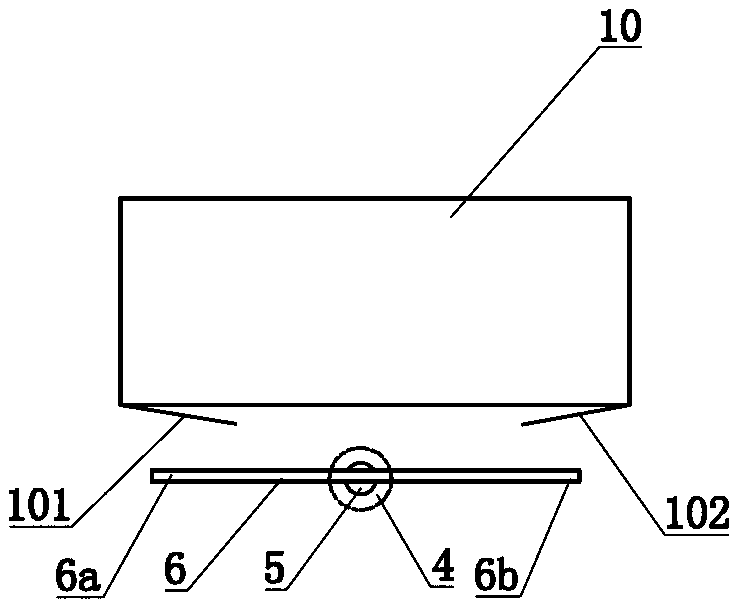

[0026] figure 1 It is the structural representation of the warped edge shaping device of the sealing tape of the present invention, the direction of the arrow in the figure is the conveying direction of the conveyor belt 9, figure 2 It is the principle schematic diagram of the control circuit of the sealing tape warping shaping device of the present invention, as figure 1 and figure 2 Commonly shown, the sealing tape edge warping shaping device of the present invention includes shaping units symmetrically installed on both sides of the conveyor belt 9, the shaping unit includes a vertically installed motor 4, and the motor 4 can adopt a stepping motor or a servo motor. The output shaft 5 of 4 is fixed with an elastic piece 6 for smoothing the warped edge of the sealing tape. On the shaft 5, the length direction of the elastic sheet 6 is perpendicular to the output shaft 5, and the elastic sheet 6 extends to both sides of the output shaft 5, and the plane where the elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com