Method for load torque limitation of a working vehicle comprising a jib

A technology for engineering vehicles and booms, applied in cranes and other directions, can solve the problems of unconsidered changes or tolerances, inability to achieve, and unfavorable accurate calculation of loads, and achieves the effect of reducing load reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments are described below.

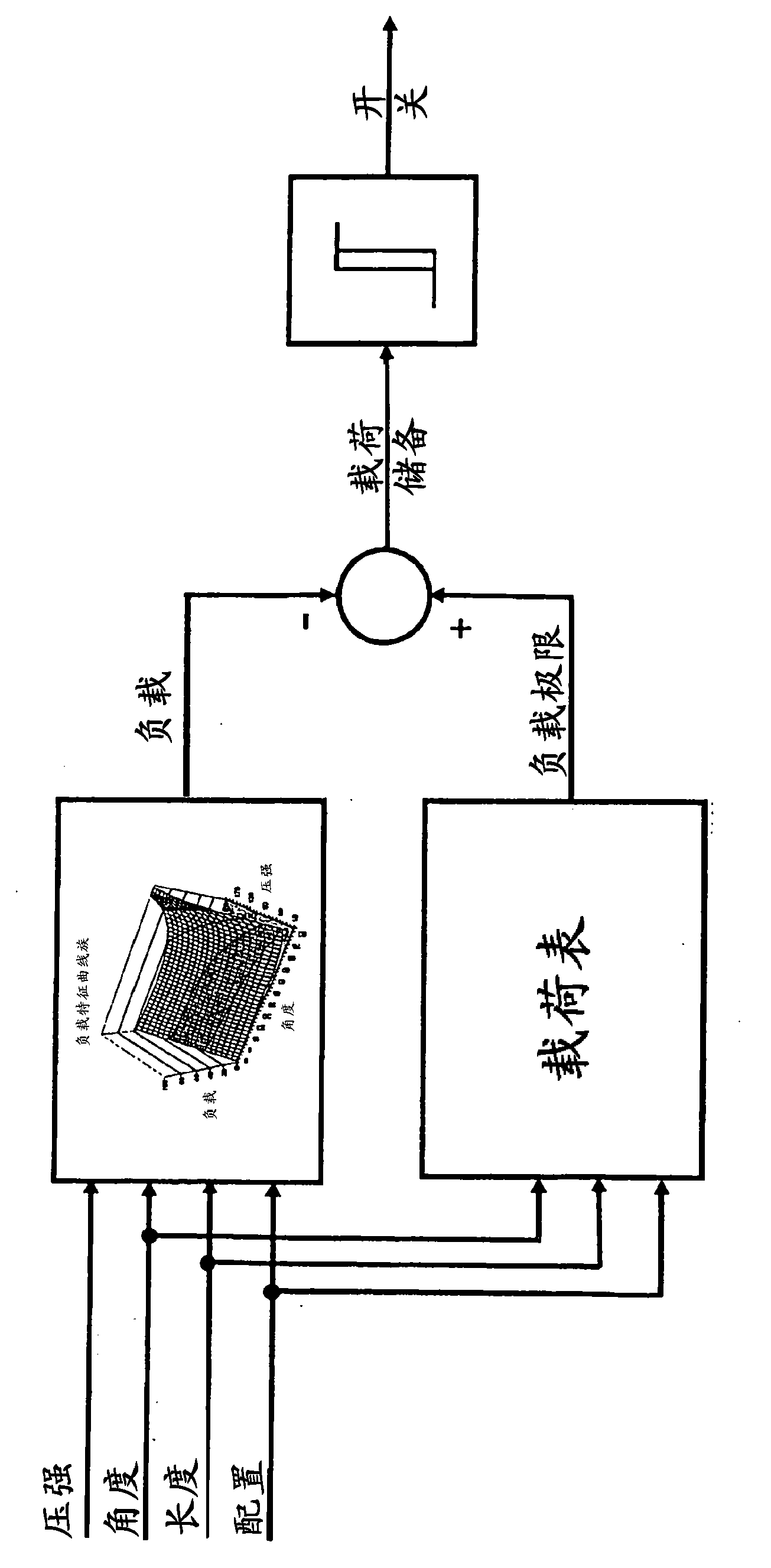

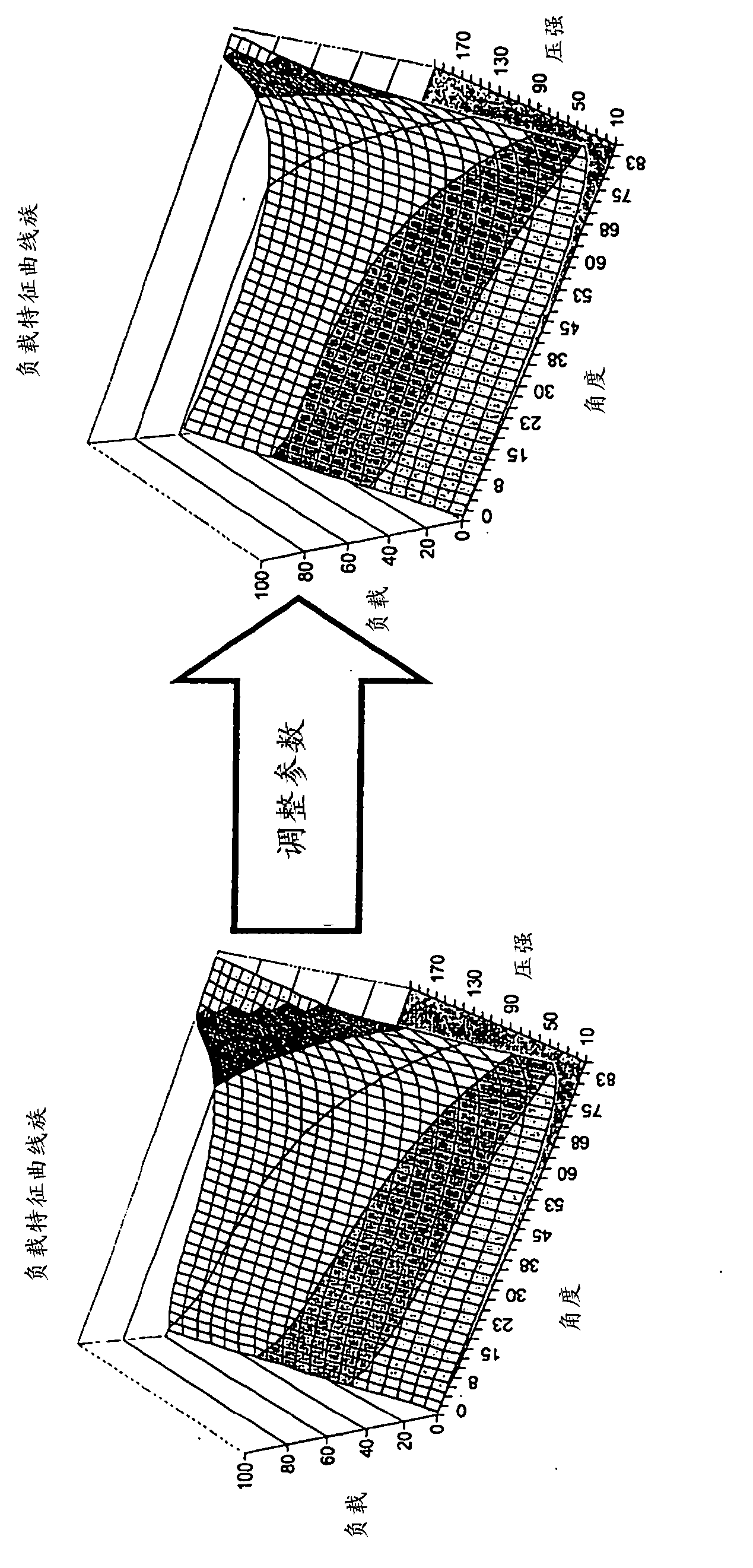

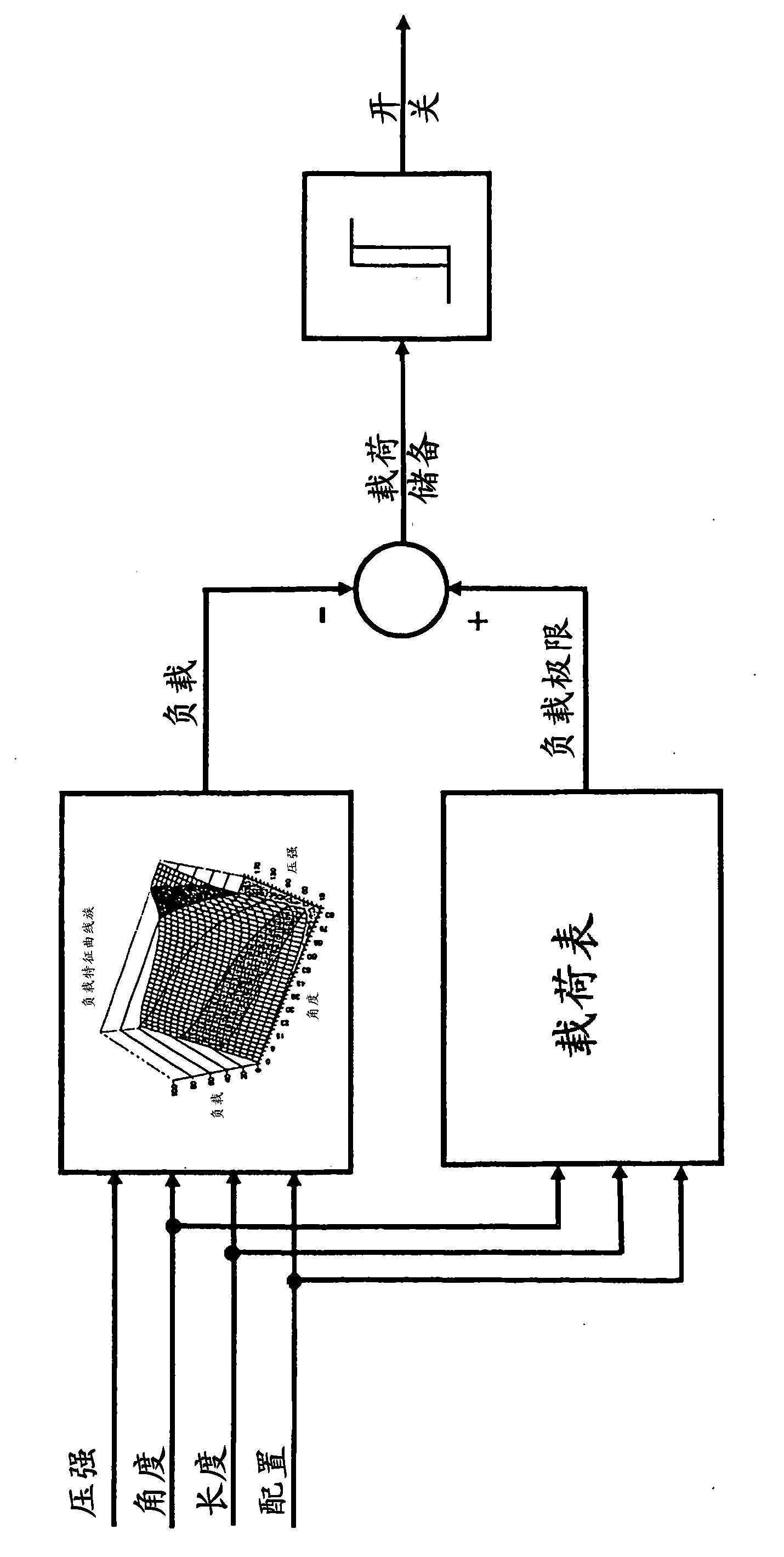

[0018] figure 1 with 2 The device for performing the method for limiting the load torque of an engineering vehicle according to the present invention is shown in detail. Similar to the arrangement shown in Figure 3, operating parameters such as pressure, angle, length, configuration, etc. are transferred to both the characteristic curve family and the load table, in which one or more multi-dimensional curve families are stored. In consideration of the calculated total potential energy of the construction vehicle and the unknown load determined thereby figure 2 The characteristic curve family stored therein is adjusted so as to provide a more accurate value of the load actually hung on the engineering vehicle compared to the load value determined by a method known in the prior art. This more accurate load value can be compared with the load limit value, which can either significantly reduce the existing load reserve to a minimum or m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com