Arc chute sheet assembling and pressing device for circuit breaker

An arc-extinguishing grid and pressing device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of complex assembly, large manual operation error, high labor intensity, etc., and achieve improved assembly efficiency and consistent assembly. Good sex and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

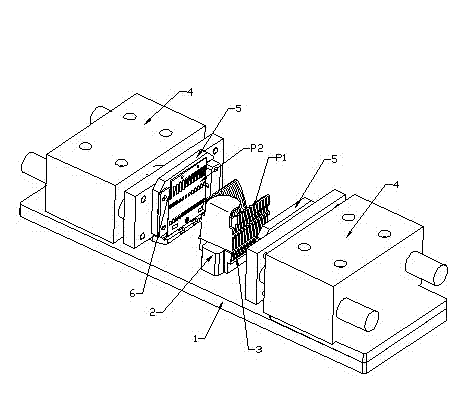

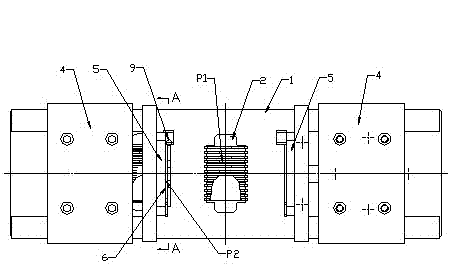

[0010] As shown in the figure, the circuit breaker arc extinguishing grid assembly and pressing device includes a base 1, a grid seat 2 is arranged in the middle of the base, and a longitudinal parallel slot 3 is opened on the grid base. The distance between the arc extinguishing grids P1 is equal, and the arc extinguishing grids to be assembled can be vertically placed in each slot 3; the front and rear of the grid seat 2 are respectively provided with a pressing plate 5 driven by a cylinder 4, and the vertical inside of the pressing plate 5 There is a concave cavity 6 matching the width of the arc breaker P2 of the product to be assembled on the straight surface. Several ball holes 7 are arranged on the side wall of the concave cavity 6. Springs 8 and balls 9 are arranged in the ball holes, so that A part of the ball 9 can elastically expand and contract on the side wall of the cavity.

[0011] Working process of the present invention is as follows:

[0012] Before pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com