Circular inverted cone type bubbling stirred tank reactor

A technology of reaction kettle and inverted cone is applied in the field of bubbling stirring reaction kettle, which can solve the problems of high power consumption, complex structure, and dead angle of stirring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

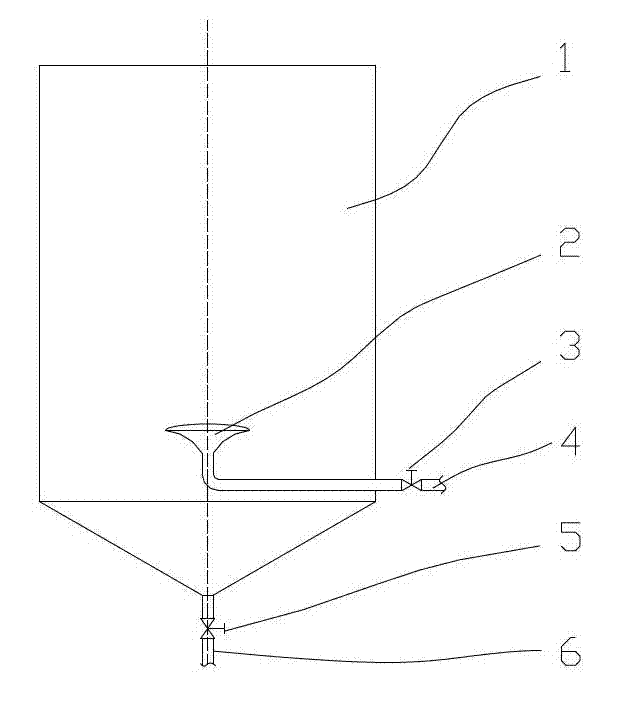

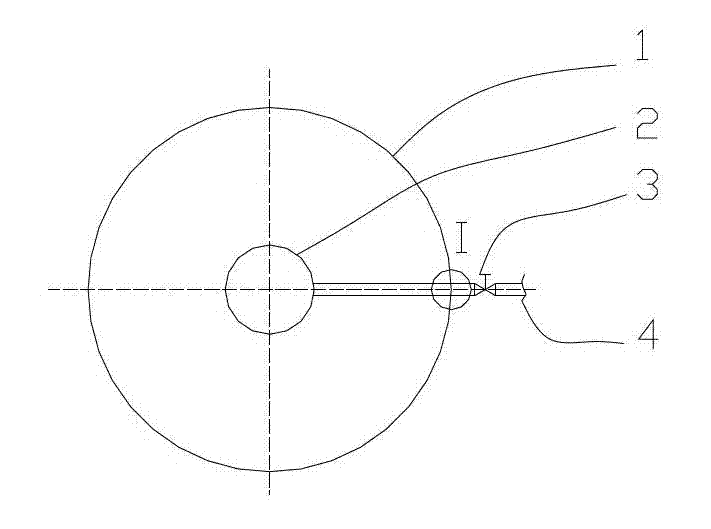

[0023] Arc inverted cone bubbling stirring reactor includes reactor 1, arc inverted cone bubbler 2, inlet valve 3, inlet pipe 4, discharge valve 5, discharge pipe 6, bubbling hole 21, inner tight Fixed screw nut 22, inner gasket 23, outer gasket 24, outer tight nut 25, ordinary fine thread 26, tapered pipe thread 27, characterized in that the center of the lower part of the reaction kettle 1 is equipped with arc inverted cone bubbling Device 2, circular arc inverted cone bubbler 2 is connected to inlet pipe 4, and inlet valve 3 is housed on the inlet pipe 4; The bottom of reaction kettle 1 is connected to discharge pipe 6, and discharge valve 5 is housed on the discharge pipe 6; The arc inverted cone bubbler is characterized in that the outer surface is an arc inverted cone, the bottom surface of the inverted cone is a convex arc surface, the side of the inverted cone is an inward concave arc surface, and the inner concave arc surface There are N bubble holes 21 of equal diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com