New soil improvement method of clayey tobacco-planting soil

A kind of foreign soil and soil technology, which is applied in the field of soil improvement of sticky tobacco planting soil, can solve the problems of unsuitable use, increase of transportation cost and workload, and ineffective effect of sand mixing amount, etc., so as to increase fertilizer efficiency utilization rate, increase The effect of soil ventilation and drainage capacity and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

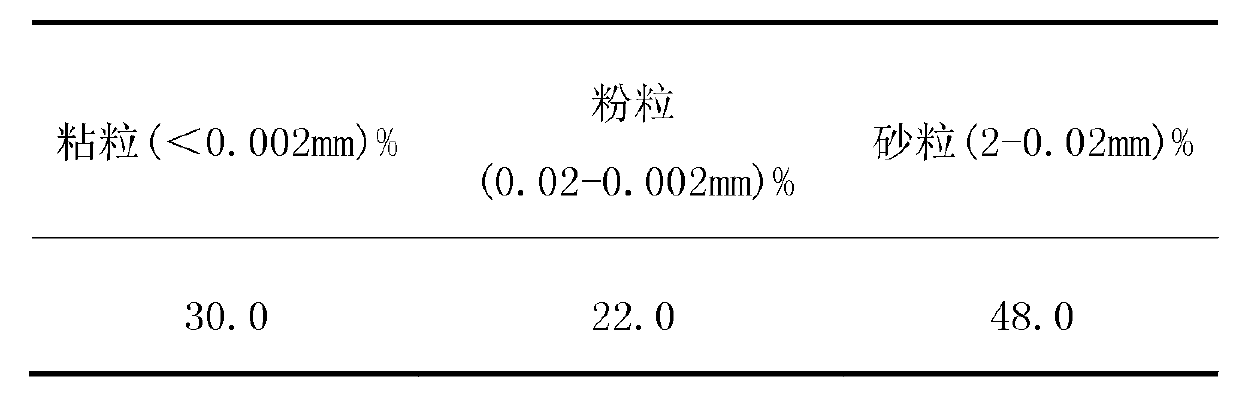

[0021] 1. The improved field is located in Guanhe Township, Huili County, Liangshan Prefecture, Sichuan Province, with an area of 2.0 mu. (Just take this field as an example, not to limit the present invention, the scheme of the present invention is applicable to soil improvement of this type in any place) After measurement, the mechanical composition of the plow layer soil before improvement is shown in Table 1:

[0022] Table 1 Soil mechanical composition before improvement

[0023]

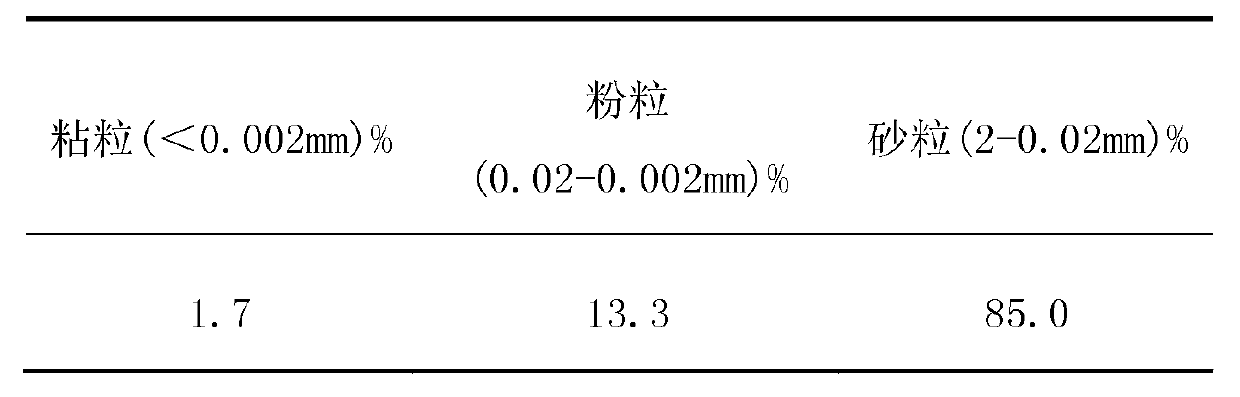

[0024] 2. The guest soil is taken from the sand and gravel soil impacted by the local river, and the mechanical composition is shown in Table 2:

[0025] Table 2 Composition of passenger soil machinery

[0026]

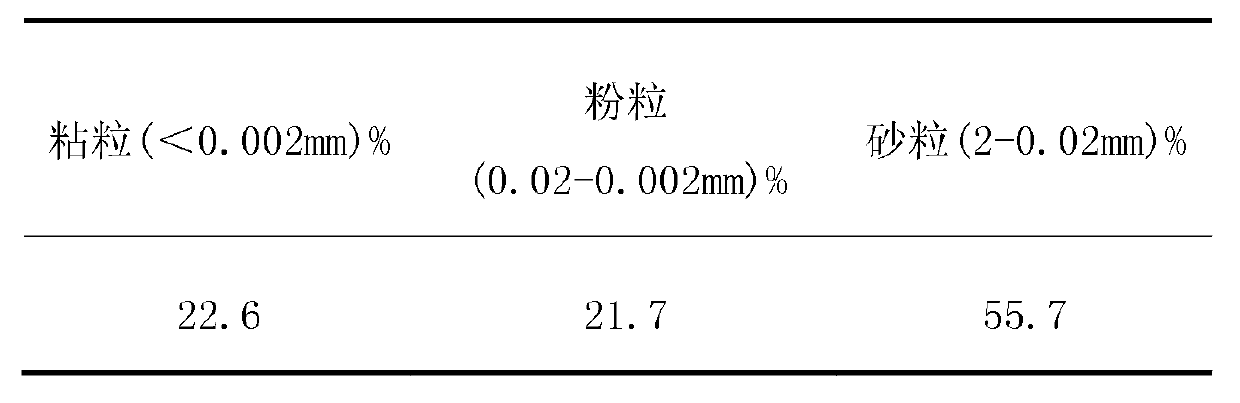

[0027] 3. Take the soil in the plow layer of the field to be improved, and mix it with the foreign soil in different proportions. After analyzing the mechanical composition of each mixed soil (with the sand content in the mixed soil > 55%, and the clay content < 23% as the tar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com