Sealing structure for rotary shaft and lamp

A technology of rotating shaft and rotating mechanism, which is applied to the sealing of the engine, engine components, and lubrication of the engine, etc. It can solve the problems that the rotating shaft cannot rotate safely and smoothly, the rubber ring cannot be used normally, and the lamp cannot be used normally. Simple and reliable, increase force balance, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

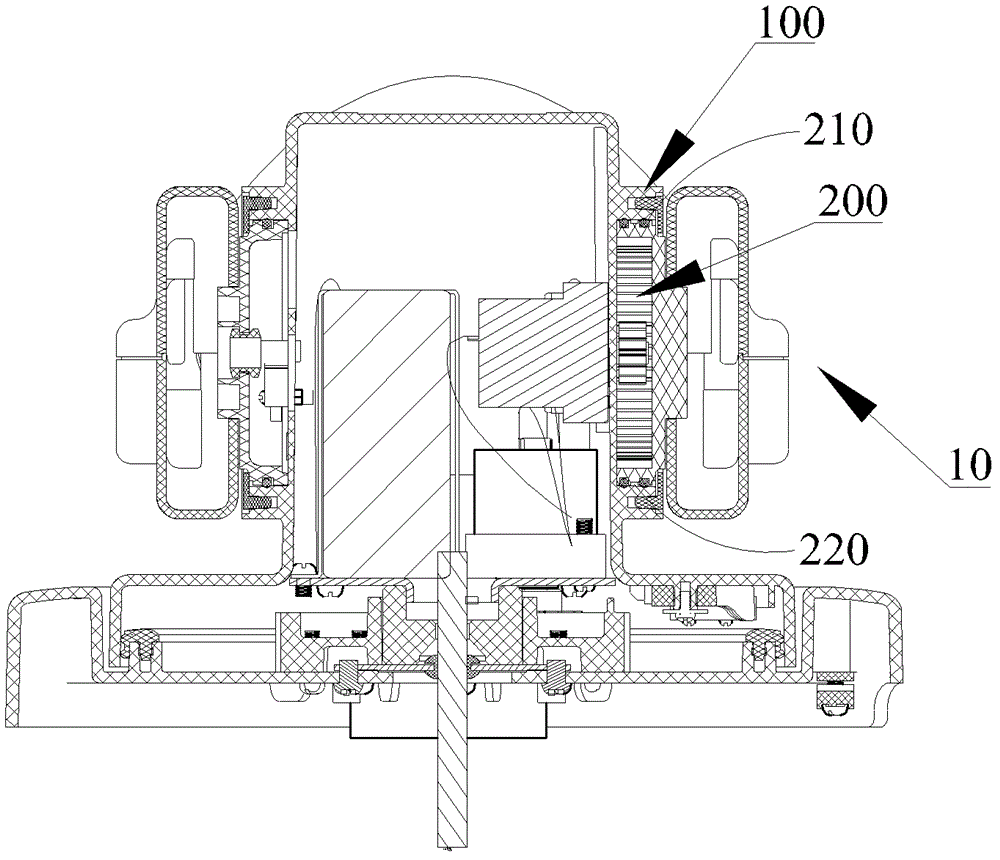

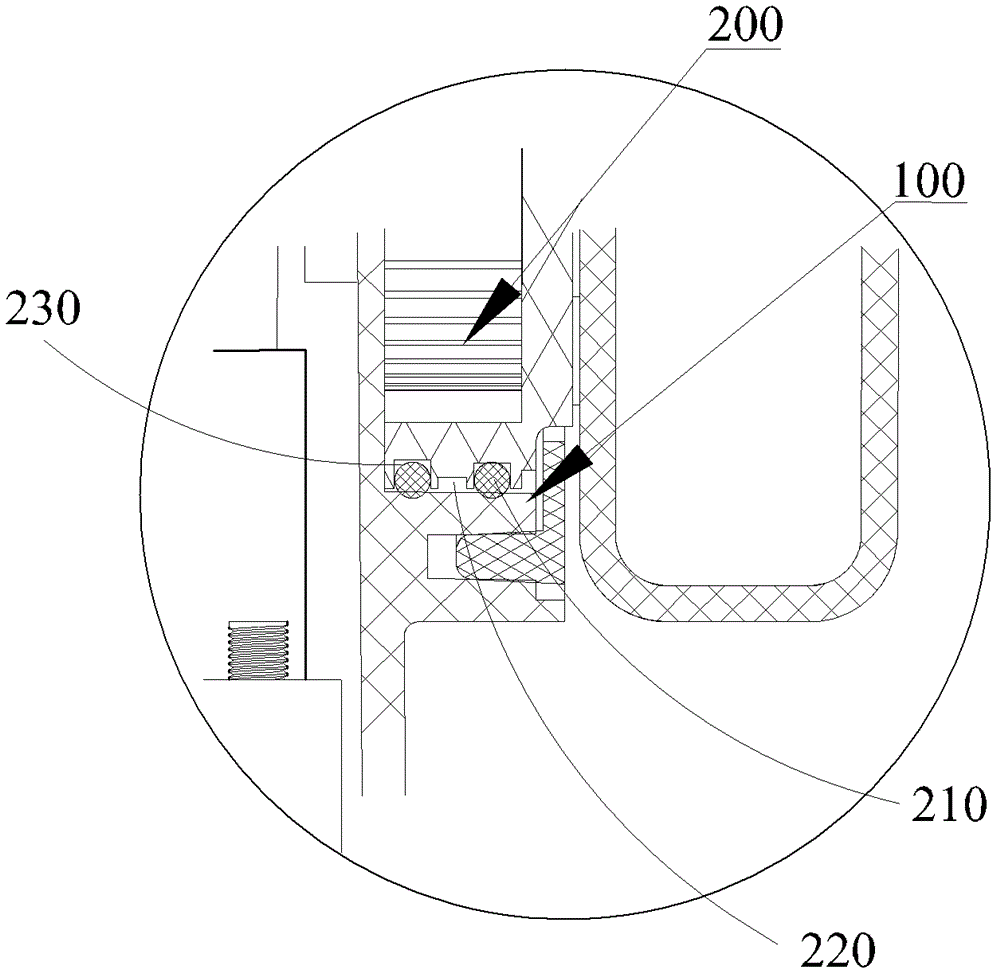

[0020] figure 1 is a structural sectional view of a lamp in an embodiment, figure 2 yes figure 1 An enlarged view of the axis of rotation 200 of the luminaire shown. combine figure 1 with figure 2 , the lamp has a rotating mechanism 10. The rotating mechanism 10 includes a bracket 100 and a rotating shaft 200 . The rotating shaft 200 passes through the bracket 100 and rotates relative to the bracket 100 . Both ends of the rotating shaft 200 along the axial direction are respectively sleeved with sealing rings 210 for sealing, and the middle part of the rotating shaft 200 along the axial direction is provided with an oil groove 220 for storing lubricating grease. The sealing ring 210 and the oil groove 220 constitute a rotating shaft sealing structure for sealing the rotating shaft 200 .

[0021] In this embodiment, sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com