Novel hollow load bearing wall

A load-bearing wall and hollow technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of poor thermal insulation effect of walls, inability to self-align seams, and not very strong bonding, etc., and achieve high construction speed. , Enhance anti-leakage performance, good shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

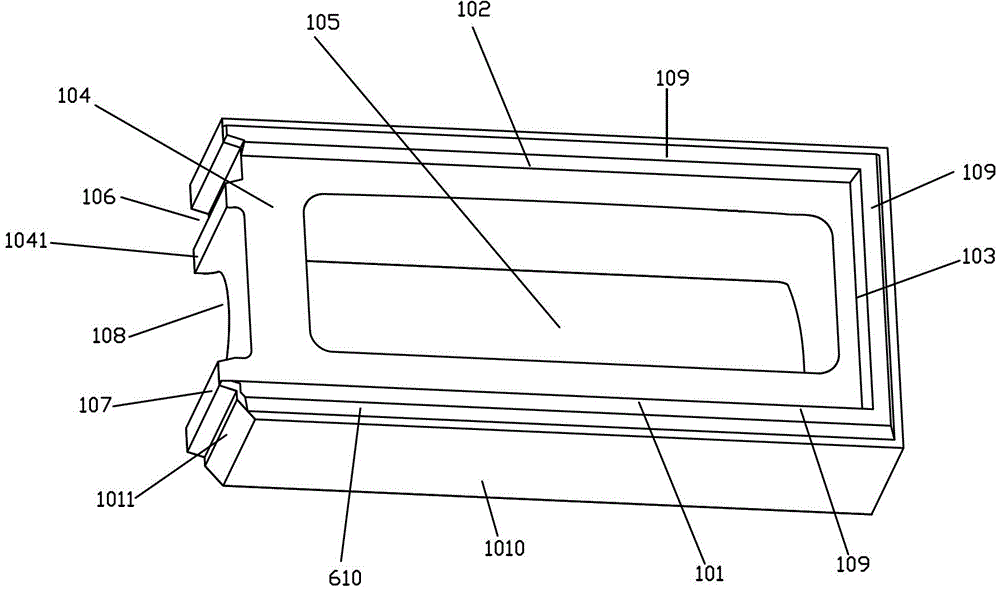

[0035] A new type of hollow load-bearing wall, which is formed by stacking several layers of corner bricks 10 on the corners and main wall bricks 11 in the middle, and the positions of the bricks on the upper and lower adjacent layers are staggered from each other;

[0036] The corner brick 10 comprises a front side 101, a rear side 102, a left side 103, and a right side 104. The middle part of the corner brick 10 is provided with a through hole 105, and the outer side of the right side 104 is The front and rear sides of 1041 are provided with corner brick vertical grooves 106 and corner brick vertical protrusions 107; the lower end surface of the right side 104 is provided with a concave arc groove 108; the front A first trapezoidal boss 109 is provided on the upper end surfaces of the side 101 , the rear side 102 and the left side 103 ;

[0037] The main wall tile 11 includes a first long side 111 and a second long side 112 arranged at a certain distance, and a rib 113 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com