Automated guide rail loopback system for railway track laying machine

A technology of a return system and a track laying machine, which is applied in the laying of tracks, roads, tracks, etc., can solve the problems of high working intensity, vulnerable workers, and uneven force, so as to ensure continuity and reliability, and improve mechanized construction. level, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

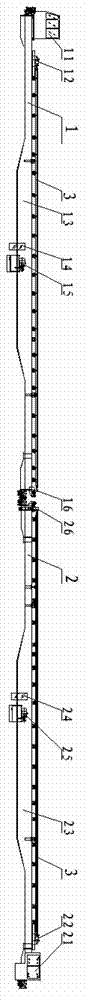

[0041] see figure 1 and figure 2 , shows a schematic diagram of the overall structure of the guide rail automatic return system of the railway track laying machine of the present invention. The guide rail automatic return system includes a main machine 1 and an auxiliary machine 2, which are used to return two parallel guide rails 3 and perform other operations.

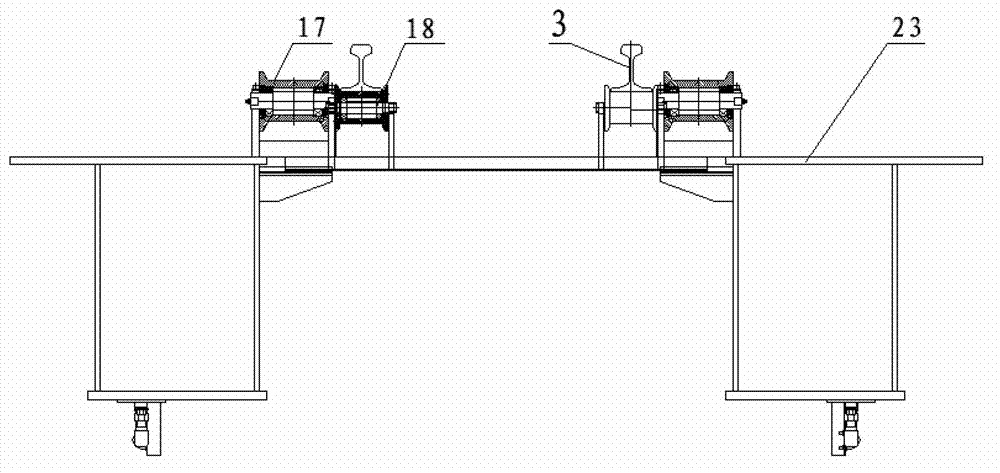

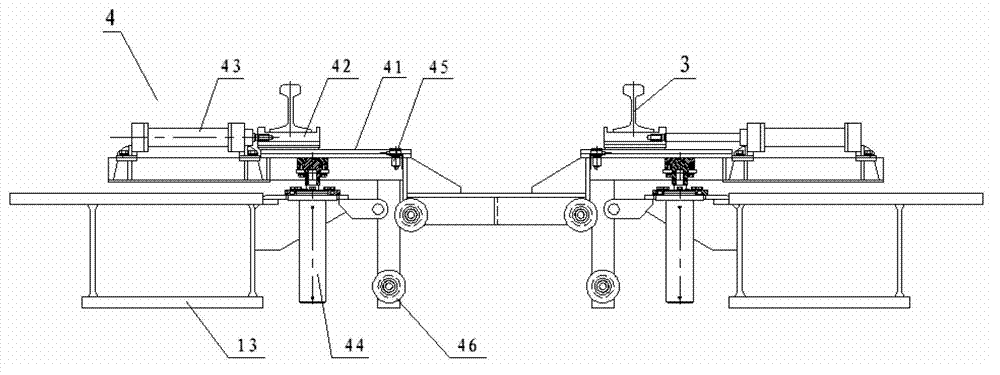

[0042] Wherein, the main engine 1 includes at least one main engine console 11, two first buffer devices 12, a main engine vehicle body 13, a main engine control box 14, a main engine hydraulic station 15, two first car sealing devices 16, a plurality of first main engine The idler roller 17 and the first secondary idler roller 18, and the main engine 1 also includes a set of electrical system and a set of hydraulic system.

[0043] The main engine console 11 is arranged on one end of the main engine vehicle body 13, and the two first buffer devices 12 are arranged side by side on the upper surface of the main engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com