Jacquard shed fast adjustment device of loaded griffe mechanism

A shed opening and knife lifting technology, which is applied in the fields of jacquard machines, textiles, textiles, and papermaking, etc., can solve the problems of reducing the strength of the sprocket adjustment, the large adjustable range of the shed, and the long stop time, etc., and reaches the adjustment range of the shed Small restrictions, fast and convenient adjustment, and the effect of saving operating hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

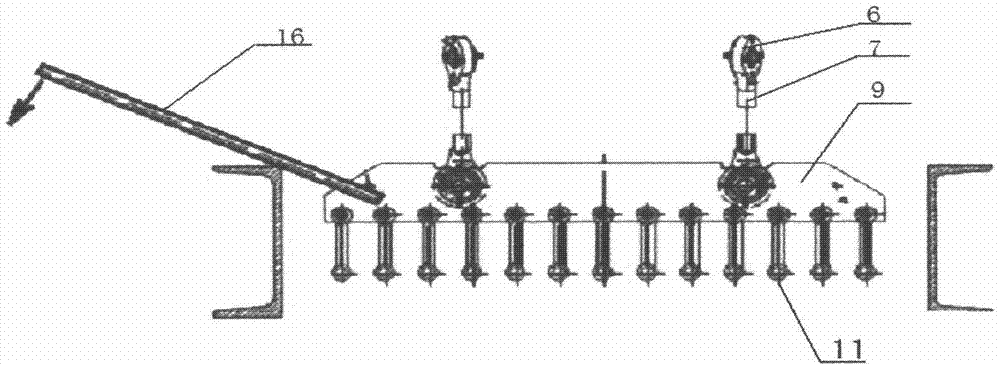

[0027] The jacquard machine shed rapid adjustment device with a load lifting mechanism includes an outer knife lifting mechanism symmetrically arranged near the outer side of the left wall panel 1L and near the outer side of the right wall panel 1R, and a shuttle symmetrically arranged above the outer knife lifting mechanism The opening adjustment mechanism, and the inner knife lifting mechanism symmetrically arranged near the inner side of the left wall panel 1L and the inner side of the right wall panel 1R, and the alternate shed adjustment mechanism arranged symmetrically above the inner knife lifting mechanism, the symmetrically arranged The inner and outer knife lifting mechanisms respectively have a pair of knife lifting frame plates, a boom set connected to the lower part of the knife lifting frame plate, and a knife lifting set correspondingly connected with the boom set.

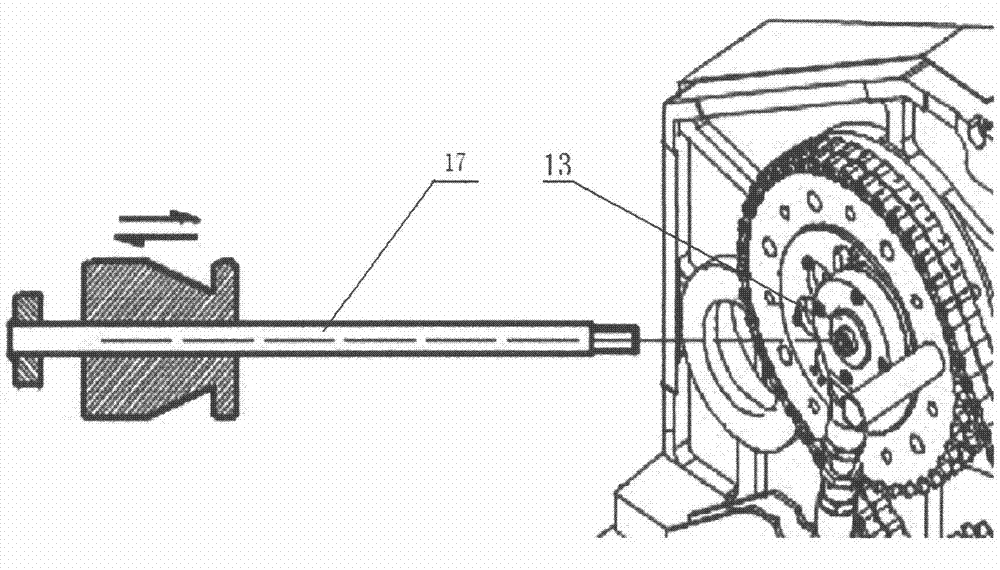

[0028] image 3 A knife-lifting plate 9a, a suspender group 91a and a knife-lifting set 9 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com