Marking compound for fertilizer, and method and device for controlled-release marking of granulated fertilizer

A granular fertilizer and coloring technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of polluting the growing environment of crops, endangering human health, and not easy to degrade, so as to improve the soil structure, improve the surface gloss, and smooth the appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

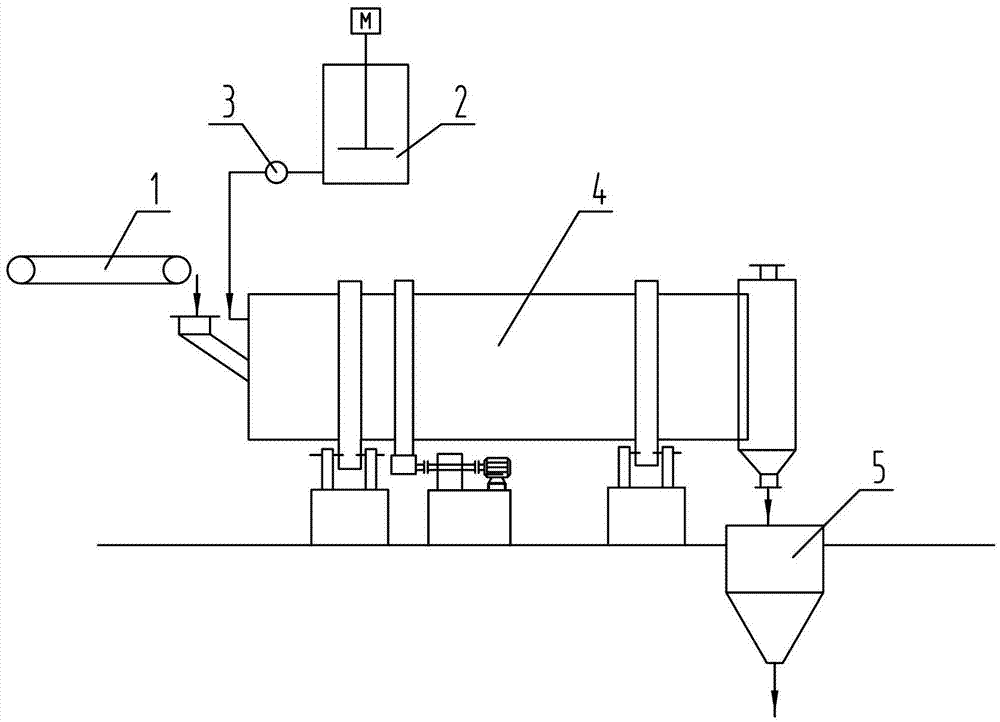

[0033] Granular fertilizer slow-release coloring device, the structure is as follows figure 1 , including: a quantitative feeder 1, a solution preparation device 2, a flow meter 3, a drum 4 and a finished product bin 5, the quantitative feeder 1 is connected to the feed port of the drum 4, and the solution preparation device 2 passes through The liquid flowmeter 3 is connected into the drum 4 , and the discharge port of the drum 4 is connected to the finished product bin 5 . The solution preparation device 2 is a pressure tank plus an air compressor, or a storage tank plus a liquid pump; the quantitative feeder 1 includes a belt scale and a conveyor belt. All components involved in the embodiments are conventional techniques in the art.

Embodiment 2

[0035] A kind of coloring agent for fertilizer, the composition of parts by weight is as follows:

[0036] 4 parts of brown dye, 15 parts of 1wt% polyvinyl alcohol solution, 2 parts of sodium water glass with a Baume degree of 25%, and 150 parts of water. The brown dye is food grade chocolate brown. Mix 1wt% polyvinyl alcohol solution, sodium water glass and water, then add dye and stir evenly.

Embodiment 3

[0038] A kind of coloring agent for fertilizer, the composition of parts by weight is as follows:

[0039] 5 parts of green dye, 20 parts of 0.8wt% polyvinyl alcohol solution, 3 parts of sodium water glass with a Baume degree of 20%, and 160 parts of water. The green dye is food-grade fruit green. Mix 1wt% polyvinyl alcohol solution, sodium water glass and water, then add dye and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com